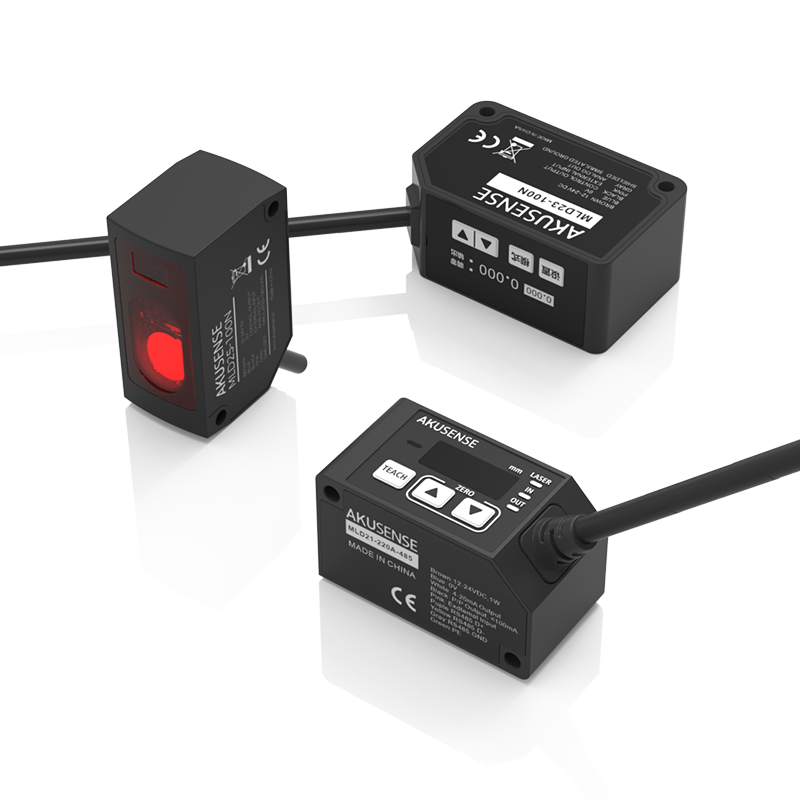

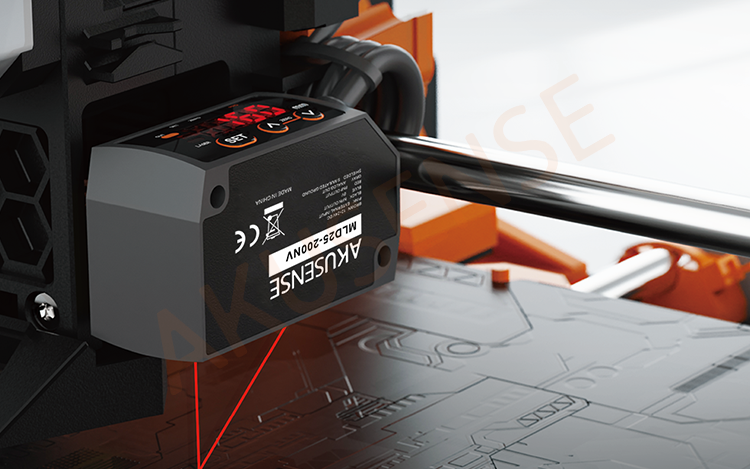

AKUSENSE MLD Laser Sensors: Micron-Level Precision for Harsh Industrial Environments

2025.06.24

Why Engineers Trust MLD Series?

1. Defy Physics, Deliver Precision

✔ Zero Flinch in Vibration: Auto-compensate up to 20g shocks

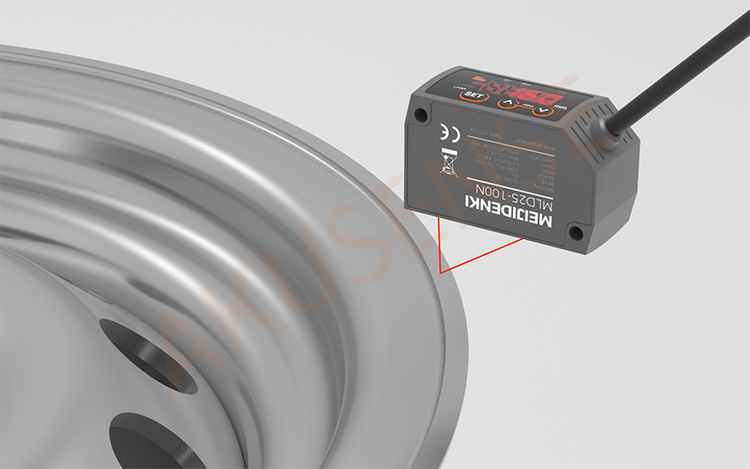

✔ Metal Surface Master: Patented Glare Suppression Algorithm for polished steel/aluminum

✔ -40 to 85 Celsius Degree Operation: Outperforms Sick/Baumer in forging plants

2. Smarter Than Standard Sensors

AI-Assisted Calibration: Self-adjust for thermal drift (saves 90% setup time)

Multi-Interface Ready: EtherCAT/RS-485/USB for PLC/robot integration

Data Logging: Store 100k+ measurements for SPC analysis

Automotive Case:

A drivetrain manufacturer reduced gear measurement errors from 12μm to 0.8μm using MLD33’s dual-axis tech, accelerating throughput by 22%.

Akusense MLD Laser Displacement Sensors Dominating Industry 4.0 Measurement

Chapter 1: The Micron-Scale Crisis in Smart Manufacturing

As global manufacturing accelerates toward Industry 4.0,a 2023 Frost & Sullivan report reveals alarming data:

-

73% of automotive plants suffer

vibration-induced measurement errorscosting $380k/hr in downtime -

68% of electronics manufacturers report

metal surface glarefailurescausing 49% false rejects -

61% of battery gigafactories battle

thermal drift inaccuraciesexceeding ±12μm

Traditional laser sensors fail to address theseIIoT integration gaps, forcing engineers into costly workarounds.

Chapter 2: MLD Series Engineering Breakthroughs

2.1 Core Photonics Architecture

-

HyperScan Technology: 650nm laser with 0.005mm resolution

-

Multi-Echo Processing: Penetrates oil/steam with 92% signal stability

2.2 Embedded Edge Computing

-

Real-time FFT vibration analysis at 50kHz sampling rate

-

Autonomous thermal compensation (-40 Celsius Degree to 125 Celsius Degree operational range)

-

On-device SPC analytics eliminating external PCs

Chapter 3: Industry 4.0 Application Mastery

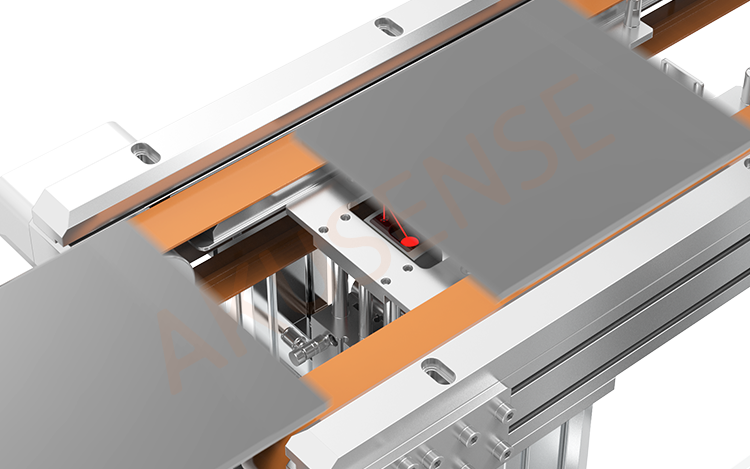

3.1 Robotic Welding Precision

-

Challenge: KUKA KR QUANTEC arms losing ±15μm positioning at 50Hz vibration

-

Solution: MLD25’s 20kHz sampling + OilDefense™ coolant resistance

-

Result: 57% downtime reduction at Bosch Rexroth

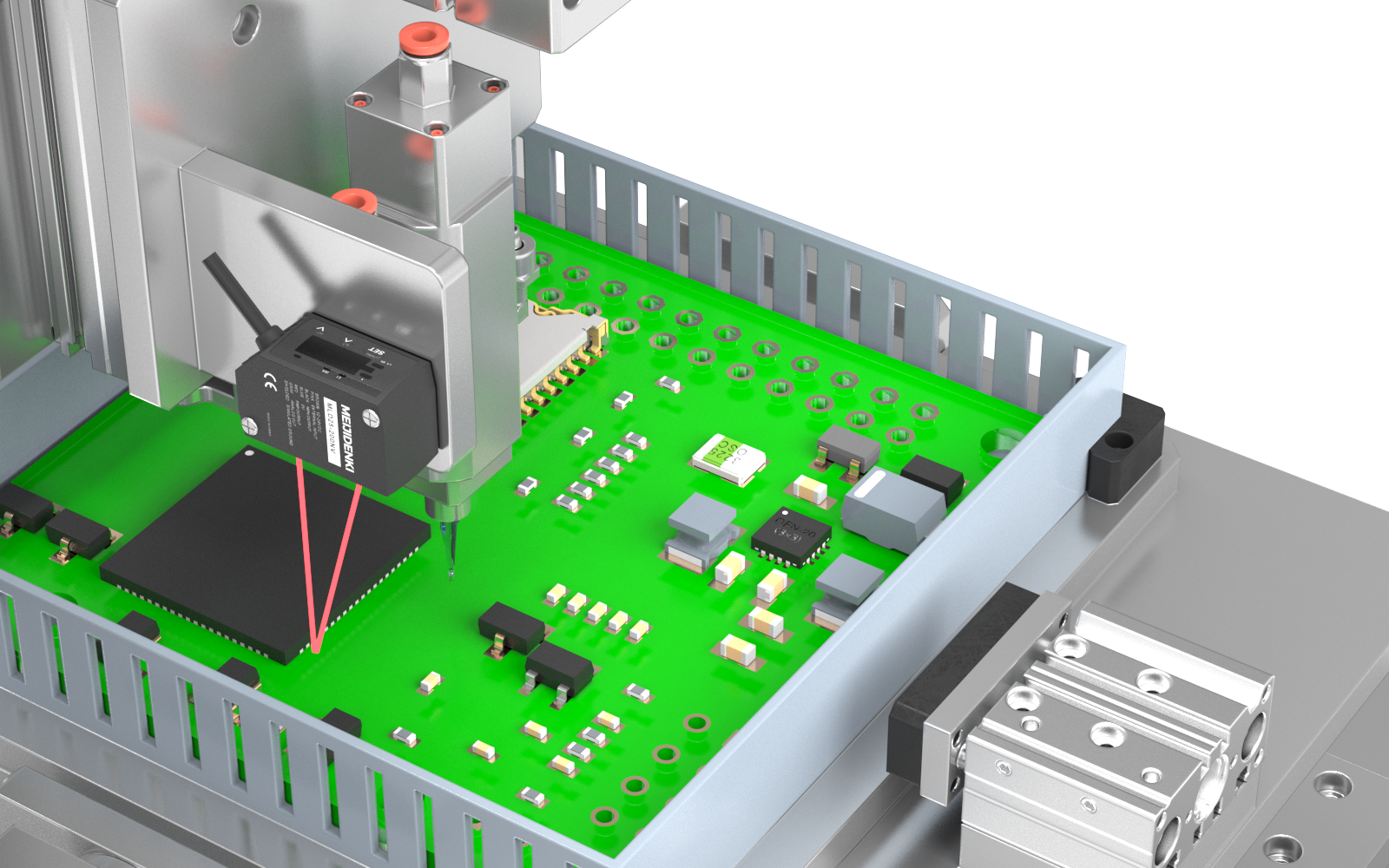

3.2 EV Battery Electrode Inspection

-

Crisis: 0.1mm coating defects triggering thermal runaway

-

Technical Edge: MLD26’s 0.005mm resolution + dynamic tilt compensation

-

ROI: CATL achieved 99.998% defect catch rate, saving $1.8M/year

3.3 Aerospace Composite Profiling

-

Precision Demand: 5μm tolerance for carbon fiber layup

Chapter 4: The Akusense Technology Ecosystem

-

Zero-Risk Deployment Protocol: 48hr global sample delivery + 3-year warranty

-

IIoT Integration Suite: Native OPC UA/EtherCAT protocols with Siemens/Rockwell templates

-

Sustainable Engineering: 95% recyclable housing

+86 18188641602