Photovoltaic oxidation process

Photovoltaic oxidation process

Photovoltaic equipment is "soaring" all the way, and their support is indispensableWith the global popularization of carbon neutrality goals, photovoltaic installations have increased rapidly. As an important supplier of photovoltaic products, domestic photovoltaic module manufacturers have a strong desire to expand production, and equipment procurement orders have soared all the way. Under the trend of rapid iteration of battery technology, capacity technology upgrades have also become the main battlefield for companies to explore value. N-type technologies represented by heterojunction, TOPcon, and IBC have appeared on the stage, and photovoltaic equipment has also ushered in a wave of replacement.

The selection and application of sensors is also a great tool for equipment manufacturers to enhance their competitiveness. With the upgrading of production needs, sensor solutions are also constantly upgrading. At present, Meiji has successively shared with you solutions for photovoltaic equipment such as photovoltaic typesetting machines and flower basket transmission equipment, revealing the sensor upgrade technology of one photovoltaic industry production workshop after another. This issue will continue to share with you the sensor application solution of oxidation process in photovoltaic equipment.

The oxidation process is a process in which silicon wafers are placed in an atmosphere of oxidants such as oxygen or water vapor for high-temperature heat treatment, and a chemical reaction occurs on the surface of the silicon wafer to form an oxide film.

01 Front-end material transportation and obstacle avoidance

Laser obstacle avoidance radar AS-33C series

Scenario requirements:

This workstation is located in the front-end material transportation process of the silicon wafer oxidation process. The laser radar is installed on the AGV car that transports the silicon wafer basket to the loading place of the rear oxidizer. One is installed at the front and back to avoid obstacles. It is required to detect obstacles within 2 meters and the response speed is required to be within 80ms

Project difficulties:

1. The workshop environment is relatively complex, so the equipment needs to adapt to the working scenes of mixed human-machine and multi-vehicle mixing

2. It is required to have equipment self-test and abnormal alarm functions

Solution:

1. AKUSENSE AS-33C model is an obstacle avoidance laser radar, which adopts the TOF measurement principle and has stable obstacle avoidance performance; 3 obstacle avoidance areas are set to meet the three states of vehicle operation, deceleration, and stop, with a detection accuracy of ±2cm

2. It can accurately measure the range of 270°, and one is installed at the front and back of the AGV car, so that the equipment can avoid obstacles without blind spots

3. With self-check function, it can detect whether the performance of the laser radar itself is abnormal, so as to avoid the equipment still operating in the event of an unexpected failure, thus causing adverse consequences

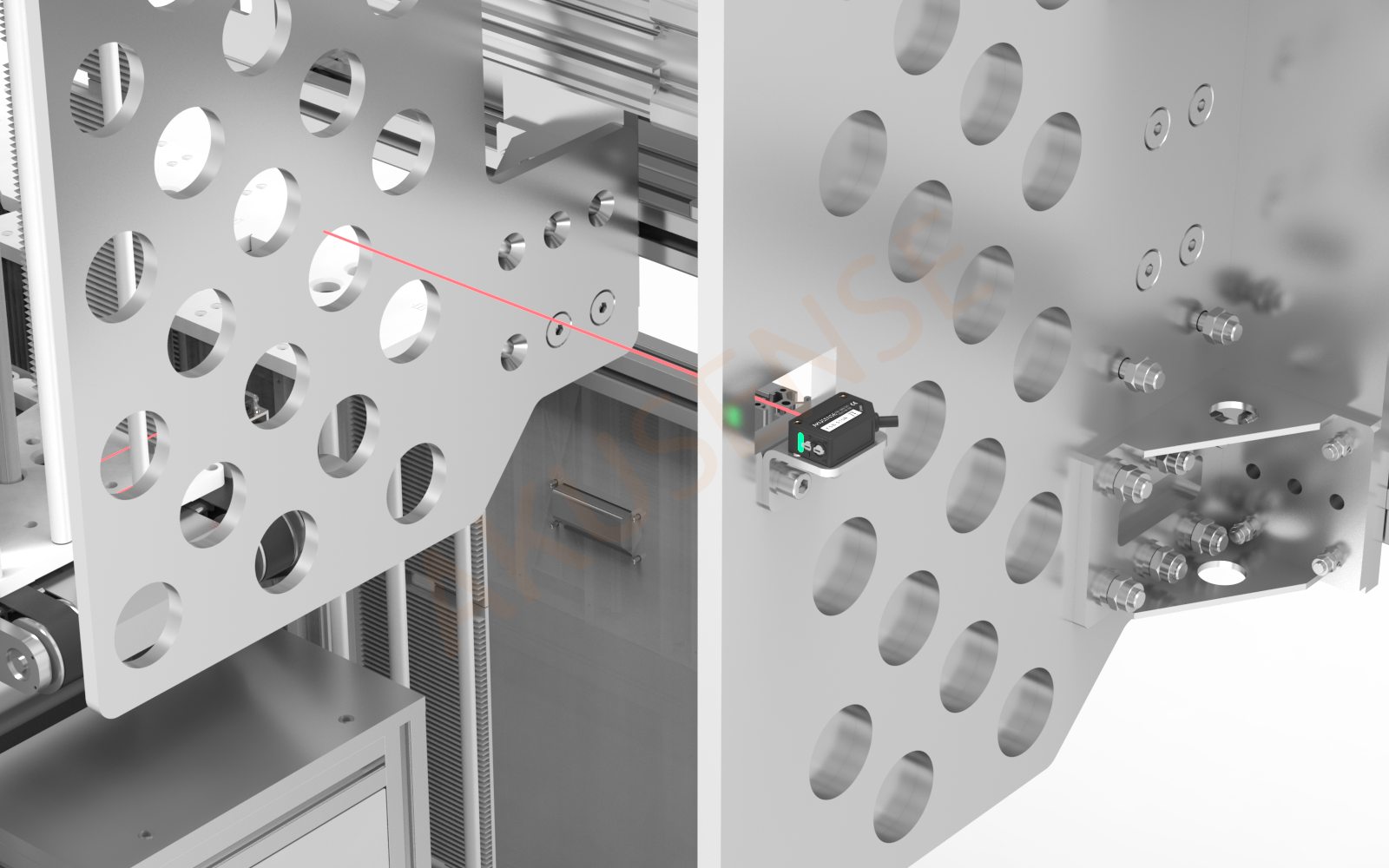

02 Protective door sensing

Proximity sensor TQN18 series

Scenario requirements:

It is necessary to install a sensor on the protective door to detect whether the door is closed tightly. The detection distance is required to be 7.5mm, and the detection repeatability accuracy is within 0.1mm

Solution:

1. It is an embedded inductive square proximity sensor with waist-shaped mounting holes for simple installation

2. The maximum detection distance is 8mm, and it is installed using M18 threads to save space

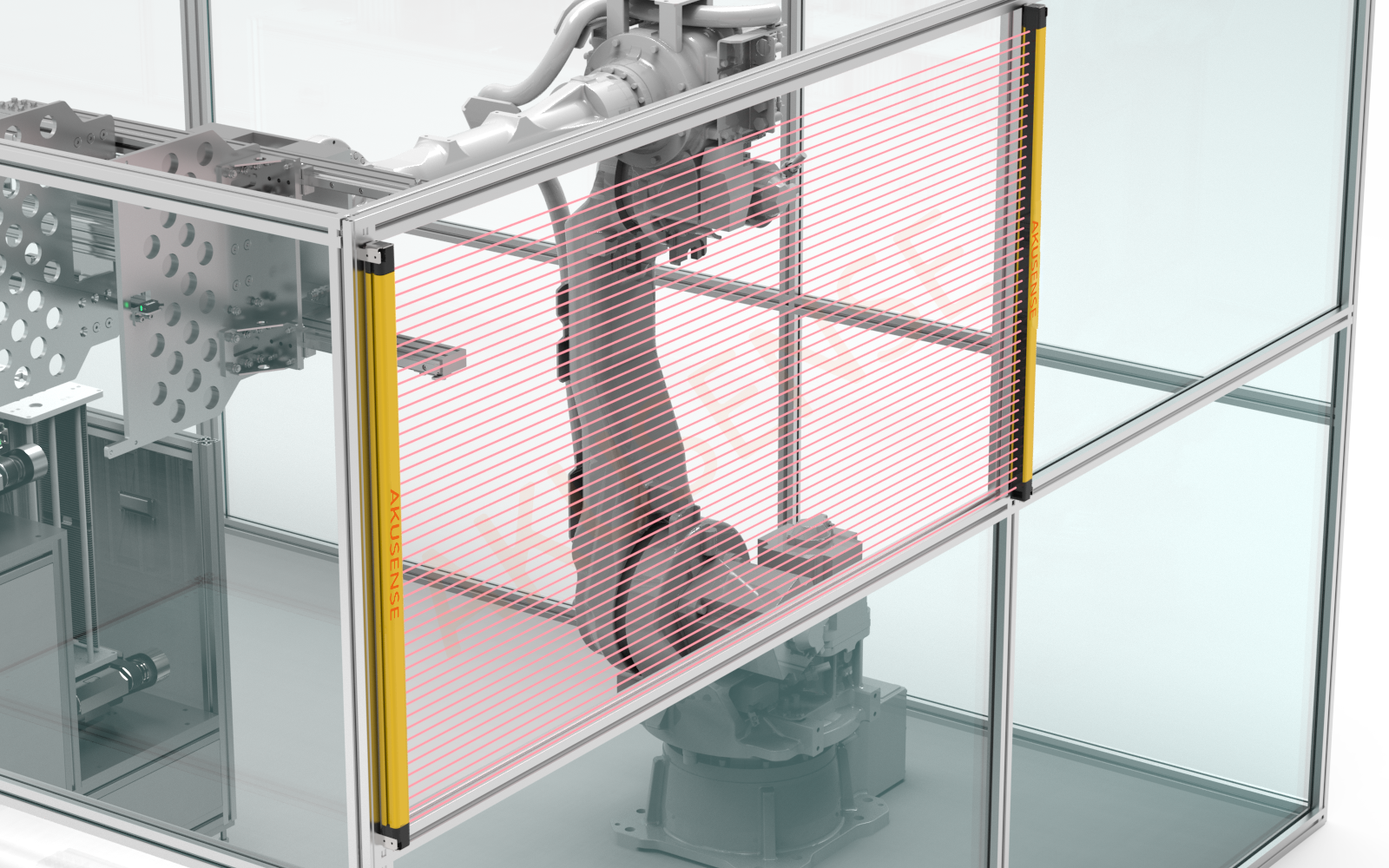

03 Regional safety protection

Safety light curtain BKL series

Scenario requirements:

Prevent personnel from entering the equipment working area by mistake and causing injury during the process of the robot grabbing silicon wafers. The response time is required to be less than 20ms and the detection is stable

Solution:

1. Use the economical light curtain BKL series, which has a variety of optical axis spacing and optical axis numbers to choose from, including 10mm, 20mm, and 40mm. Here, we need to protect the human body. We recommend choosing a 40mm optical axis spacing

2. Fast response time, less than 10ms. Once the human body enters, a signal is immediately sent to drive the machine to pause, which plays a role in protecting the human body

3. Strong anti-light interference ability, can withstand a maximum of 10000lux interference, and is not affected by other stray light on site

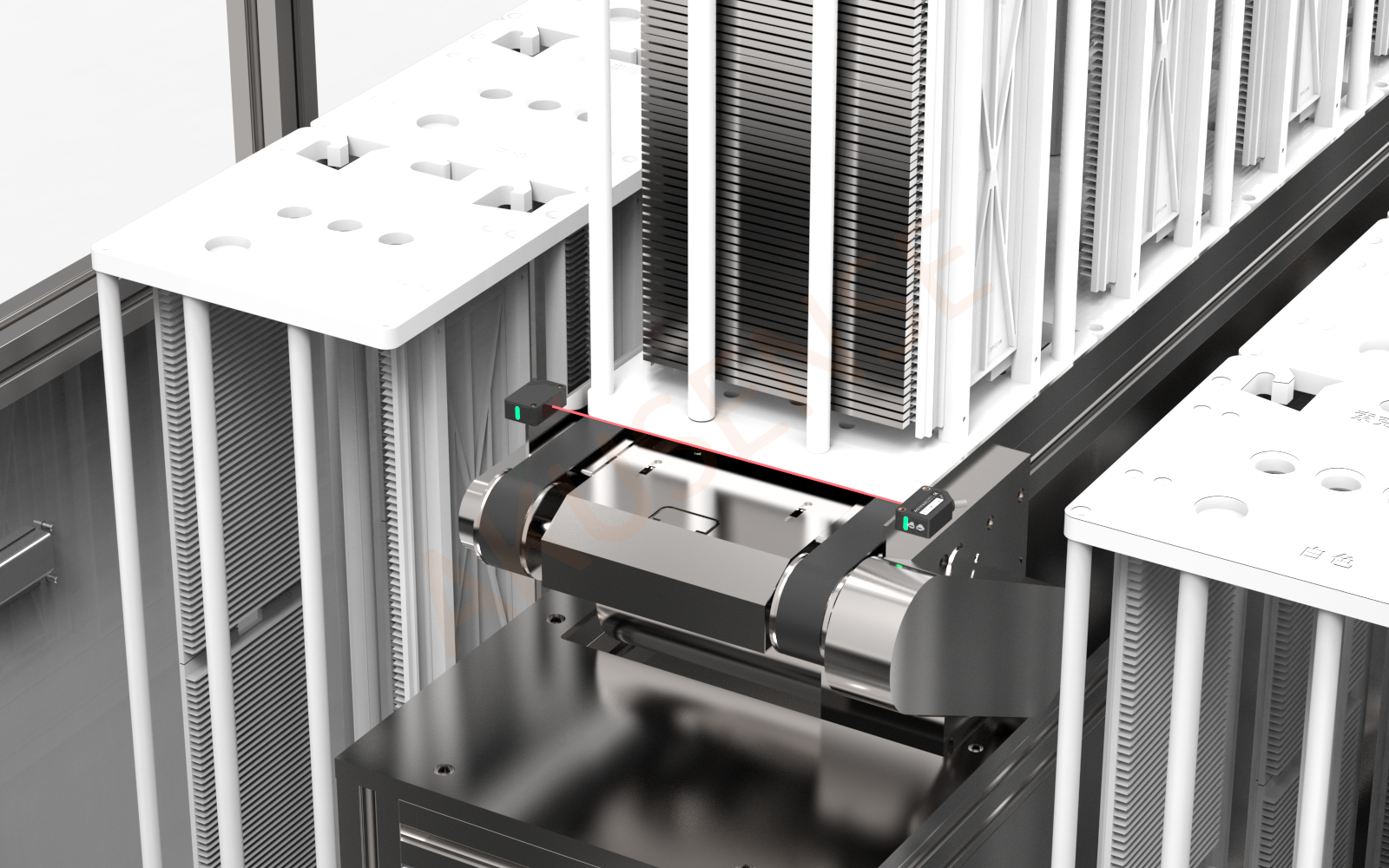

04 Robot silicon wafer grabbing induction

Background suppression photoelectric sensor ESB-S10 series

Scenario requirements:

This station is located in the middle of the silicon wafer oxidation process. A sensor needs to be installed to detect whether the robot has grabbed the silicon wafer in order to enter the next process. The detection is required to be stable and the detection distance is 50mm

Solution:

1. Install 3 background suppression photoelectric sensors ESB-S10 series on the manipulator, which are not affected by the background color and can stably detect materials of any color.

2. The detection distance is 5-100mm, which can meet the needs.

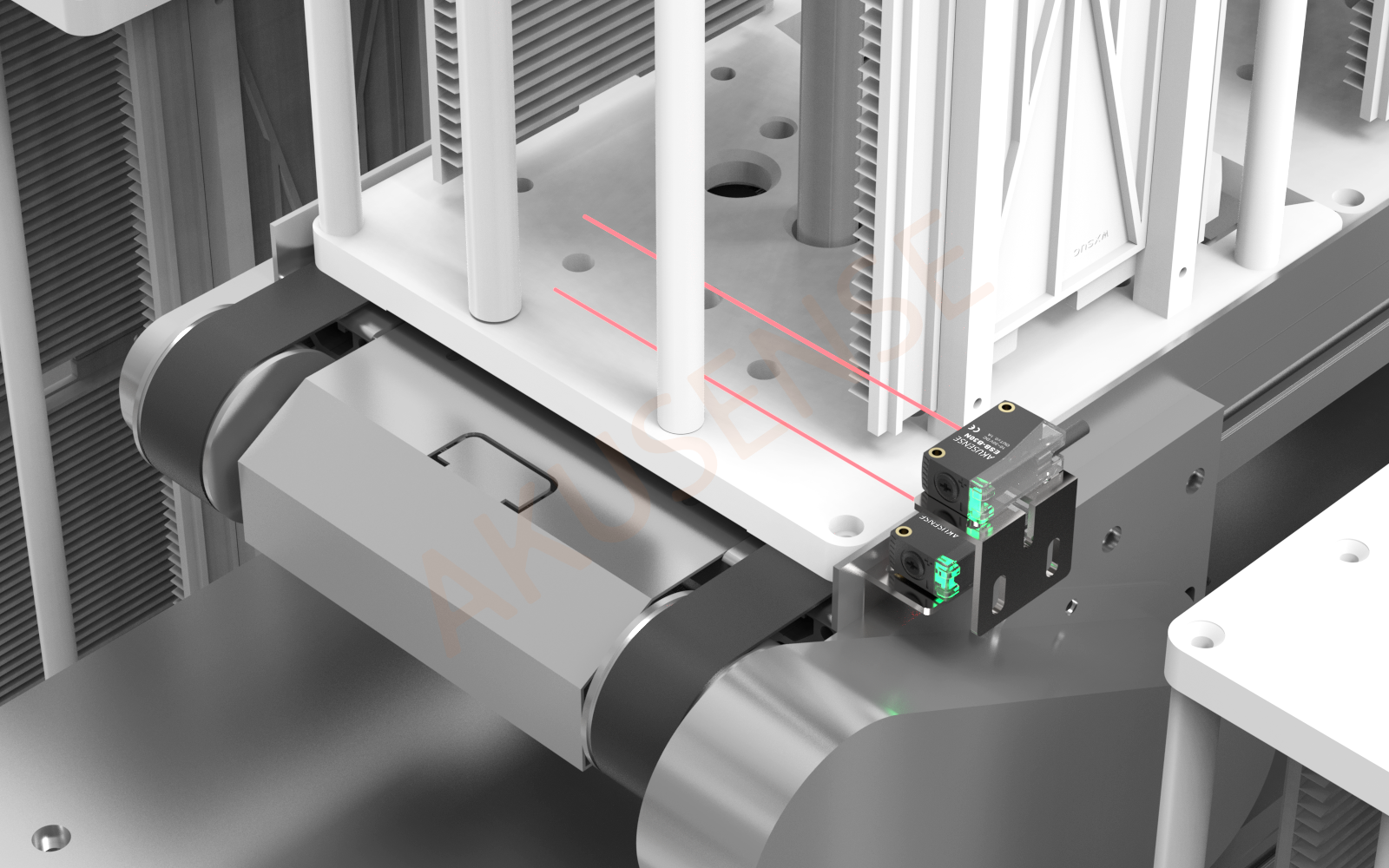

05 Wafer stacking height control

Background suppression photoelectric ESB-B30 series

Scenario requirements:

This station is located in the silicon wafer oxidation process, receiving materials transported by the manipulator, and has requirements for the silicon wafer stacking height. It is necessary to stop stacking after the materials are stacked to the specified height; the detection distance is 250mm, there is an LED lighting, and the ambient light is strong, which will interfere with the sensor. The response time is required to be less than 1ms. In addition, the customer has high requirements for detection accuracy and requires a repeatability accuracy of less than 0.5mm. At the same time, this equipment will also produce various types of silicon wafers, requiring a sensor to be compatible with all products.

Project difficulties:

There are high requirements for the sensor's ability to resist light interference, and it needs to be able to resist the interference of high reflection of silicon wafers and strong surrounding light at the same time.

Solution:

1. Use two background suppression photoelectric sensors ESB-B30N series to be installed in parallel above and below the silicon wafer stacking limit height, which is not affected by the background color and can ensure the detection compatibility of various types of silicon wafers

2. The sensor detection distance can reach 250mm, which can meet customer needs in this scenario. The detection distance is adjustable and can be adjusted through the top knob, which is convenient for installation and debugging

3. The response time is less than 1ms, which can ensure the detection efficiency while ensuring stable detection, and the light spot is small and the detection accuracy is high

4. It has strong anti-light interference ability, the sunlight can reach 10000lux, the incandescent lamp can reach 3000lux, and the anti-stray light interference ability is strong, and it is not affected by the floor surface under the robot, the metal surface of the equipment, the glass surface of the doors and windows, and the reflection of the silicon wafer

5. The sensors can be installed side by side at zero distance, and there will be no mutual interference when installed side by side at close distance

+86 18188641602