Empowering injection molding machines with super "plastic" power

Empowering injection molding machines with super "plastic" power

The Injection molding machine is widely used in industrial production. They are used to inject molten plastic or other plastic materials into molds, cool and solidify them, and finally form the required plastic products or parts.The Injection molding machine is widely used in industrial production. They are used to inject molten plastic or other plastic materials into molds, cool and solidify them, and finally form the required plastic products or parts.

As one of the important industrial mother machines, it involves a wide range of downstream products, and the finished products range from toys, lighters, and mobile phone shells to electric vehicle frames and automobile plastic bumpers, covering all aspects of life and production.

With the development of injection molding machines and the continuous expansion of the international market, China has become the world's largest injection molding machine producer, and the export volume of injection molding machines has increased and is generally on the rise. The Data shows that chinese injection molding machine exports volume in 2022 is 60,578 units, increasing 22.20% year-on-year. With the surging wave of Industry 4.0, the demand for intelligent injection molding machines has also become one of the focuses of attention of giants.

This case will show the application of AKUSENSE on the injection molding machine of a leading socket company

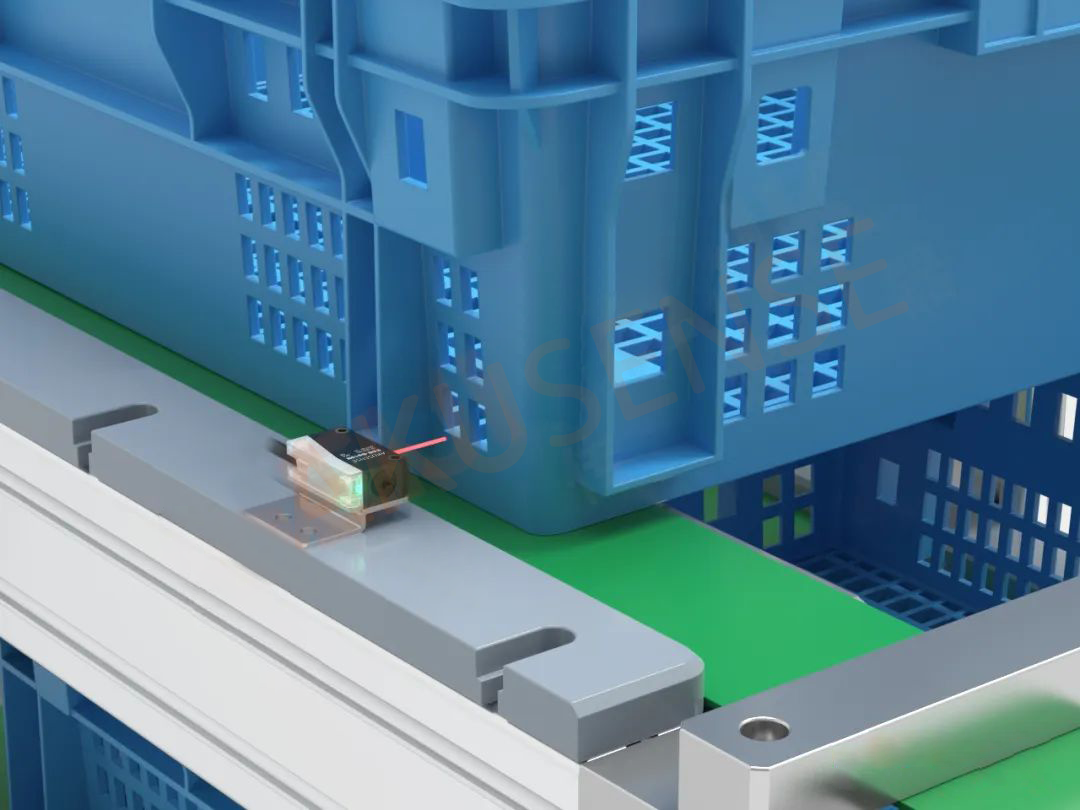

01 Material box transmission detection

Background suppression photoelectric ESB-BS15N

Application scenario:

When the material box is transported to the assembly line by the AGV, a sensor needs to be installed to detect whether the material box is in place to trigger the next station action

Detection difficulties:

1. The box body is of various colors/various sizes/There is a chance that there will be residual paper material order numbers on the box body, and the sensor is required to be unaffected by the object being measured

2. The size of the sensor bracket detection hole is small, and the sensor spot size is required to be small and not affected by the detection hole

3. There is a high-brightness LED light above the equipment, which will cause external light interference to the photoelectric sensor

4. Part of the equipment structure uses acrylic board. Protection may cause the sensor to abnormally reflect part of the light, which may cause the risk of false signal triggering

Solution:

1. A background suppression photoelectric sensor ESB-BS15N is used, which is not affected by color. The sensor uses a dynamic filtering algorithm inside to achieve the best detection effect in various environments.

2. High-precision optical lens design makes the sensor's light spot clearer and brighter, and the light spot is small

3. The product has strong anti-light interference ability, sunlight can reach 10,000 lux, the incandescent lamp can reach 3,000 lux, and stable detection is still possible when there is lighting interference during equipment operation

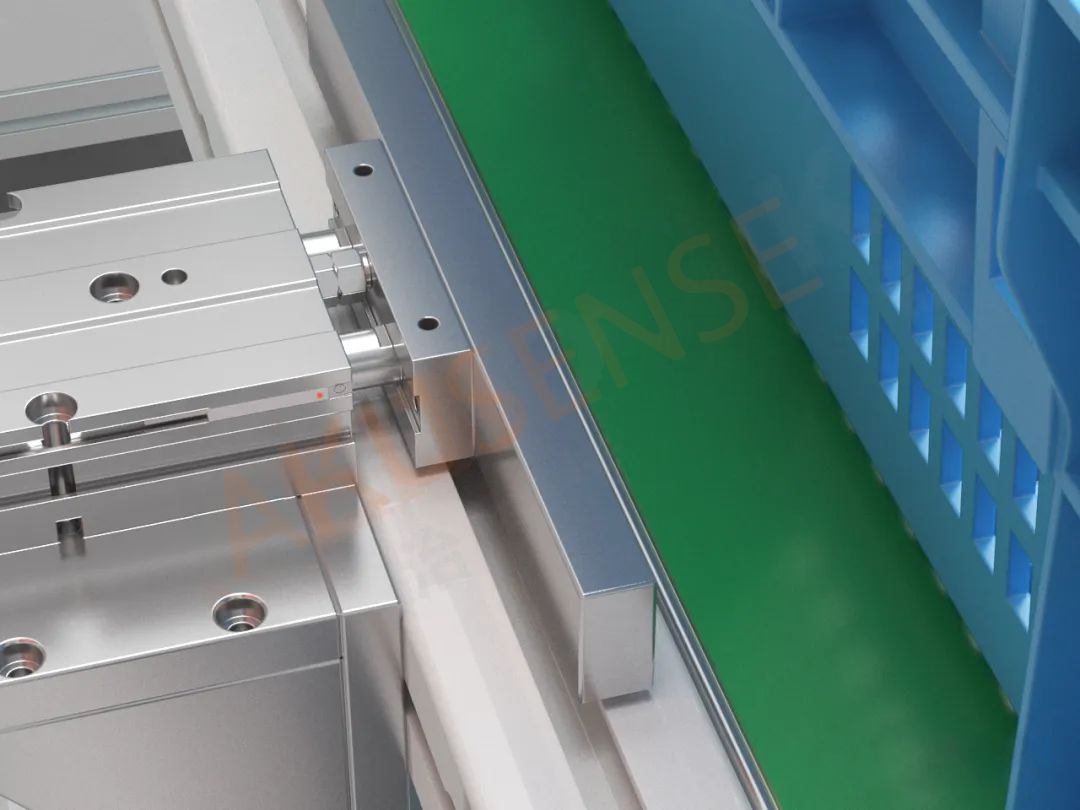

02 Detection of cylinder extension

MR-C81 cylinder sensor

Application scenario:

When the material box enters the waiting area of the streamline, the cylinder will extend to block it. A cylinder sensor is needed to detect whether the extension is in place

Solution:

1. MR-C81 series cylinder sensor, with high positioning accuracy, reliable performance, and surge absorption protection

2. The maximum switching frequency can reach 1000Hz, and high-speed scenes can be stably detected

3. The sensor is resistant to vibration or heat (temperature resistance up to 70℃) and has strong anti-interference in harsh environments

4. IP67 protection level, dustproof and waterproof, rejecting various interference factors

5. Small size, can be integrated in various narrow installation environments

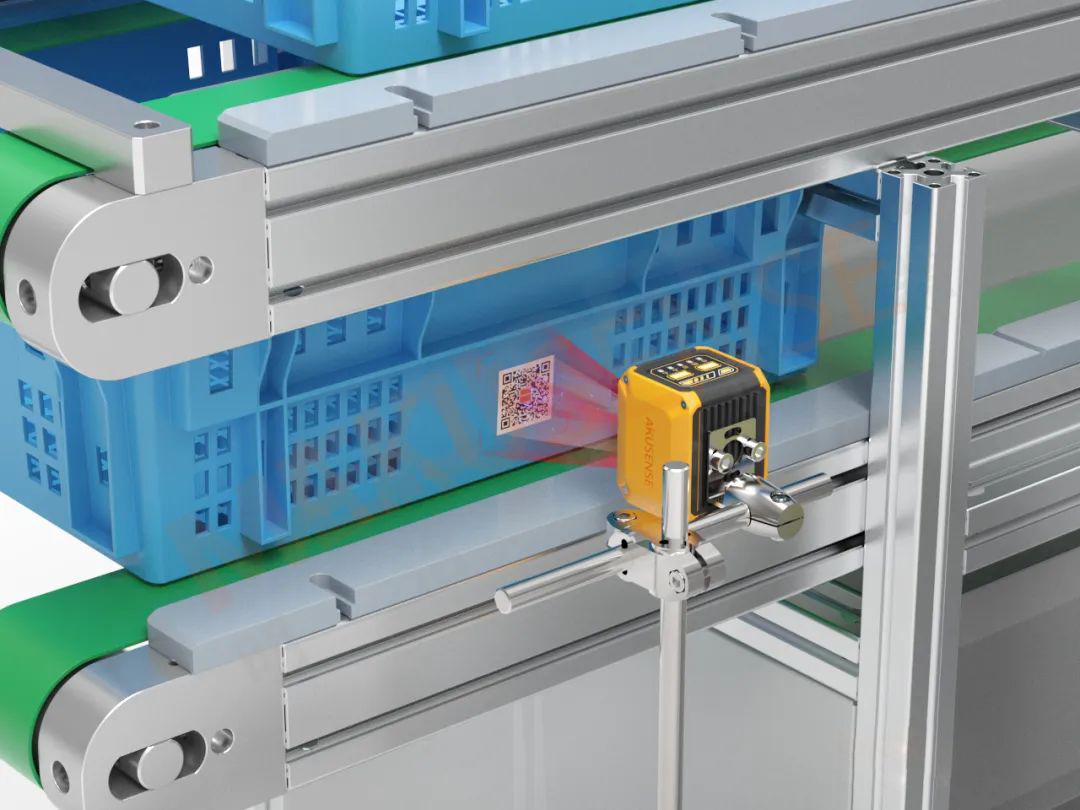

03 Material box QR code reading

Smart code reader RCD-AI100-X08WD

Application scenario:

When the material box is filled and flows to the discharge port through the transmission line, a code reader needs to be installed to identify the QR code information on the box and send it to the AGV transporter

Detection difficulties:

1. The code reader is required to quickly identify the QR code on the box

2. The light at the discharge port is dim, and the code reader needs to be able to identify the QR code in a dim scene

3. The width of the discharge flow line is wide/the position of the QR code on the box will have a certain position deviation, which will affect the recognition effect of the code reader and the response time of the output signal

Solution:

1. RCD-AI100 series intelligent code reader, configured with Cortex 4-core processor, single core up to 1.8GHz, maximum reading speed 60/second, can stably detect high-speed moving objects

2. Adopt ultra-flexible light source system, red/white light can be customized according to the scene, 4 groups of light sources can be independently controlled, high flexibility

3. Cover the mainstream code reading distance, the maximum reading distance is 1000mm, the field of view can reach up to 480*300mm, even if the position of the QR code has a certain deviation, it will not affect the recognition effect

04 Handling module suction cup negative vacuum pressure monitoring

MQ-03D series Barometer

Application scenario:

After each layer of material is placed in the material box, the negative pressure suction cup on the handling module will suck the protective film and place it on the material to prevent the material from being stacked randomly

Solution:

1. MQ-03D series barometer, the product has undergone more than 2000W pressure shock tests and output signal reliability tests before leaving the factory, and the service life is guaranteed

2. The sensor response speed is 1ms, and all pressure gauges of the same type on the market have the same repeatability as well-known Japanese brands

3. The sensor is equipped with an analog module inside, which can output analog voltage & current, making it more convenient to use

4. Products can be customized according to customer needs, and openness meets product upgrades

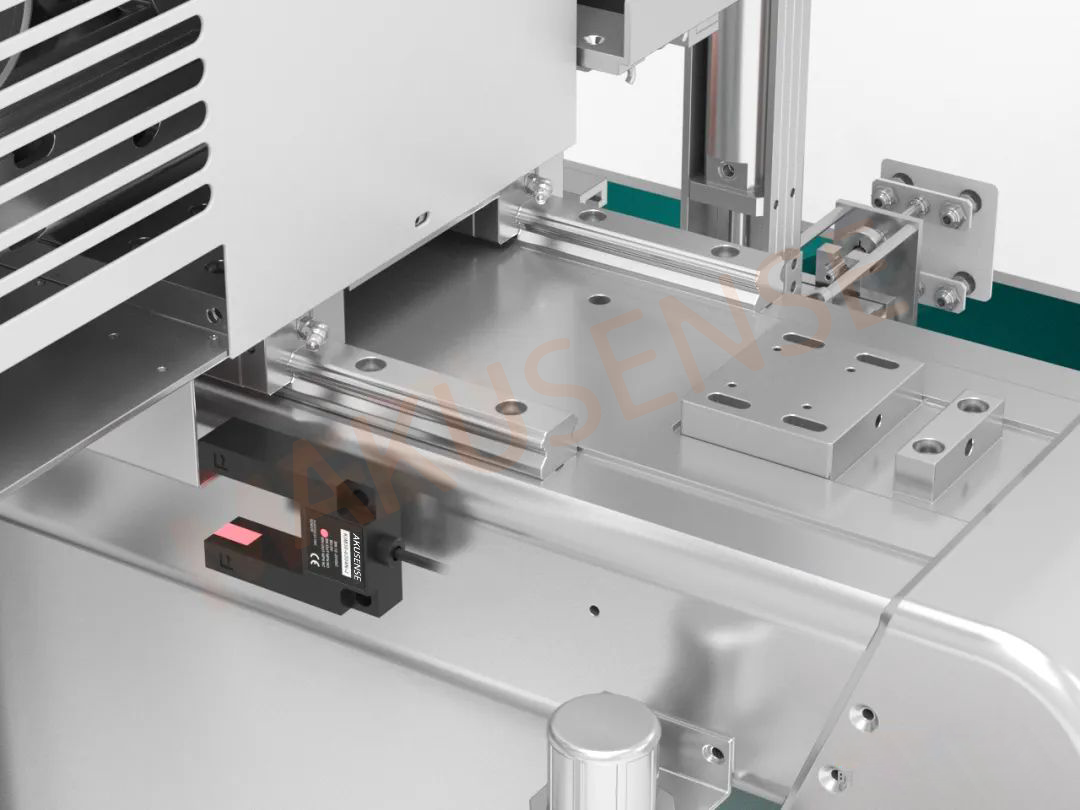

05 Servo module position detection

Operation sensor KIM30-0304N-J

Application scenario:

After the injection mold is formed, the servo module will move to a fixed position to absorb the finished product and place it in the material box. The slot sensor is used to detect whether the moving action is in place. The repeatability is high and less than 0.5mm; the response is fast and needs to be less than 1ms; there is a stepper motor next to the workstation, which will generate an electromagnetic field during the work process and interfere with the sensor

Solution:

1. Excellent anti-interference performance, good stability of the beam detection principle

2. The response speed is less than 0.6ms, the detection accuracy is high, the repeatability is 0.01mm, and the output mode is optional

3. Non-contact detection, long service life, and convenient wiring

06 Protection module in place to ensure

Safety door lock AR3-4M1UA

Application scenario:

When the PVC liquid dissolved at high temperature flows through the pipeline to the injection mold, a protection module will be configured above the pipeline to prevent the high-temperature liquid from splashing. Requires installation of protective devices, high tensile strength when locked, shielding protection function; requires sensors to be dustproof, waterproof, and shock-resistant

Solution:

1. AR3 series security door locks can operate stably in -10℃-55℃ environment; protection level is IP67 high protection level, meeting various scenarios and working environments

2. The service life of the sensor is up to 100W plug-in and pull-out times, the internal hardware adopts precision design, and the forced pull-out strength is 1300N when locked

+86 18188641602