Battery cover

Battery cover

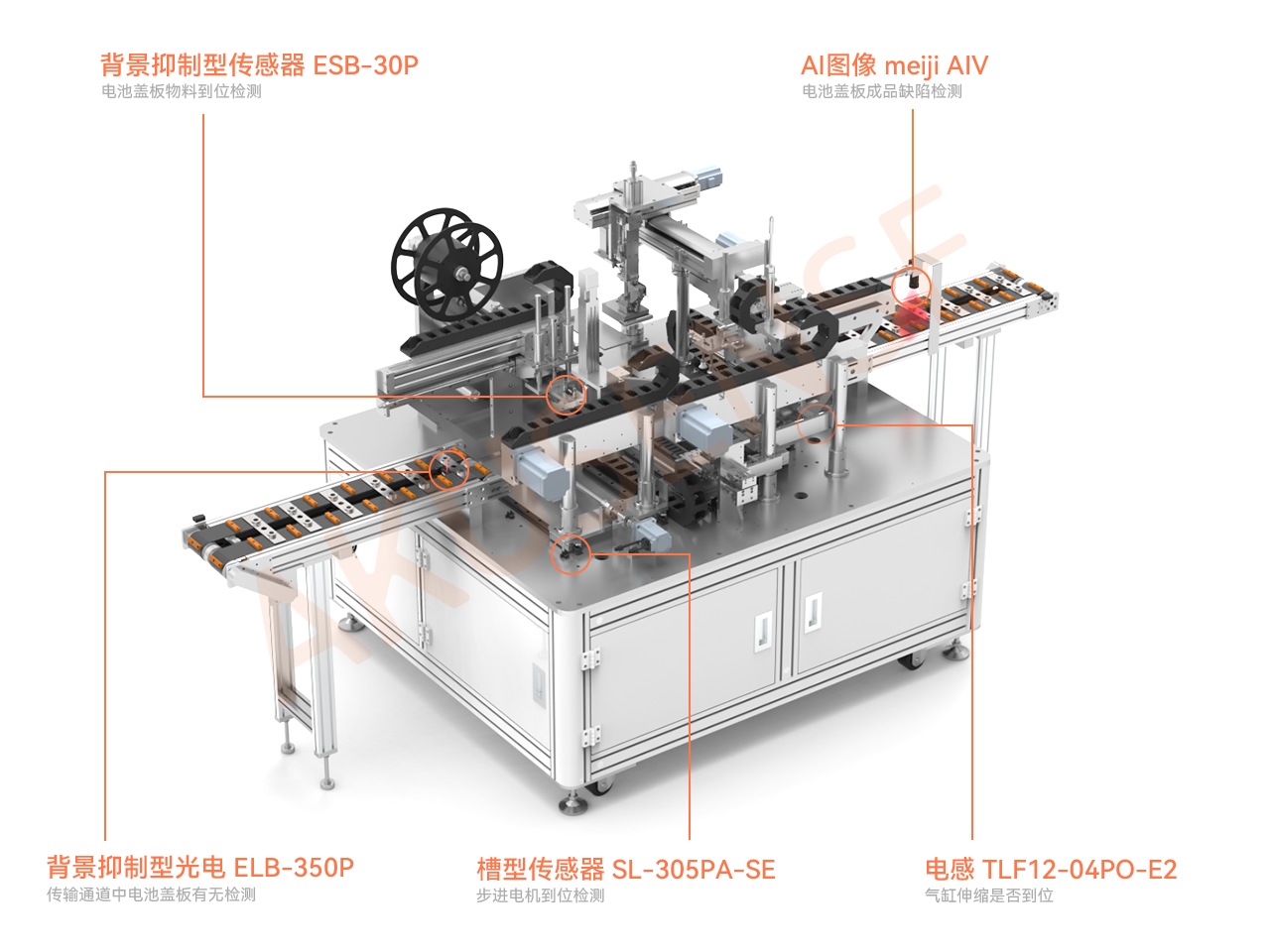

To create a smart solution for new energy battery cover, these sensors are indispensableIn the wave of new energy industry development, batteries play a pivotal role.

Each square battery shell is composed of a shell and a cover. The battery cover is the core component to ensure the safety of lithium batteries. It seals the shell with the battery cell, outputs the internal energy, and ensures the key component of the battery cell safety. It has strict requirements on the sealing of components, the pressure relief pressure of the safety valve, electrical performance, size and appearance.

AKUSENSE has mature solutions for the fully automatic assembly and testing production line of battery covers. In this issue, Xiao Ming will share with you AKUSENSE's solution in battery cover-shaping equipment.

This solution aims to help automated equipment realize the automation, dataization and systematization of cover shaping, which can greatly improve the shaping quality and efficiency of battery covers and ensure the qualified rate of products.

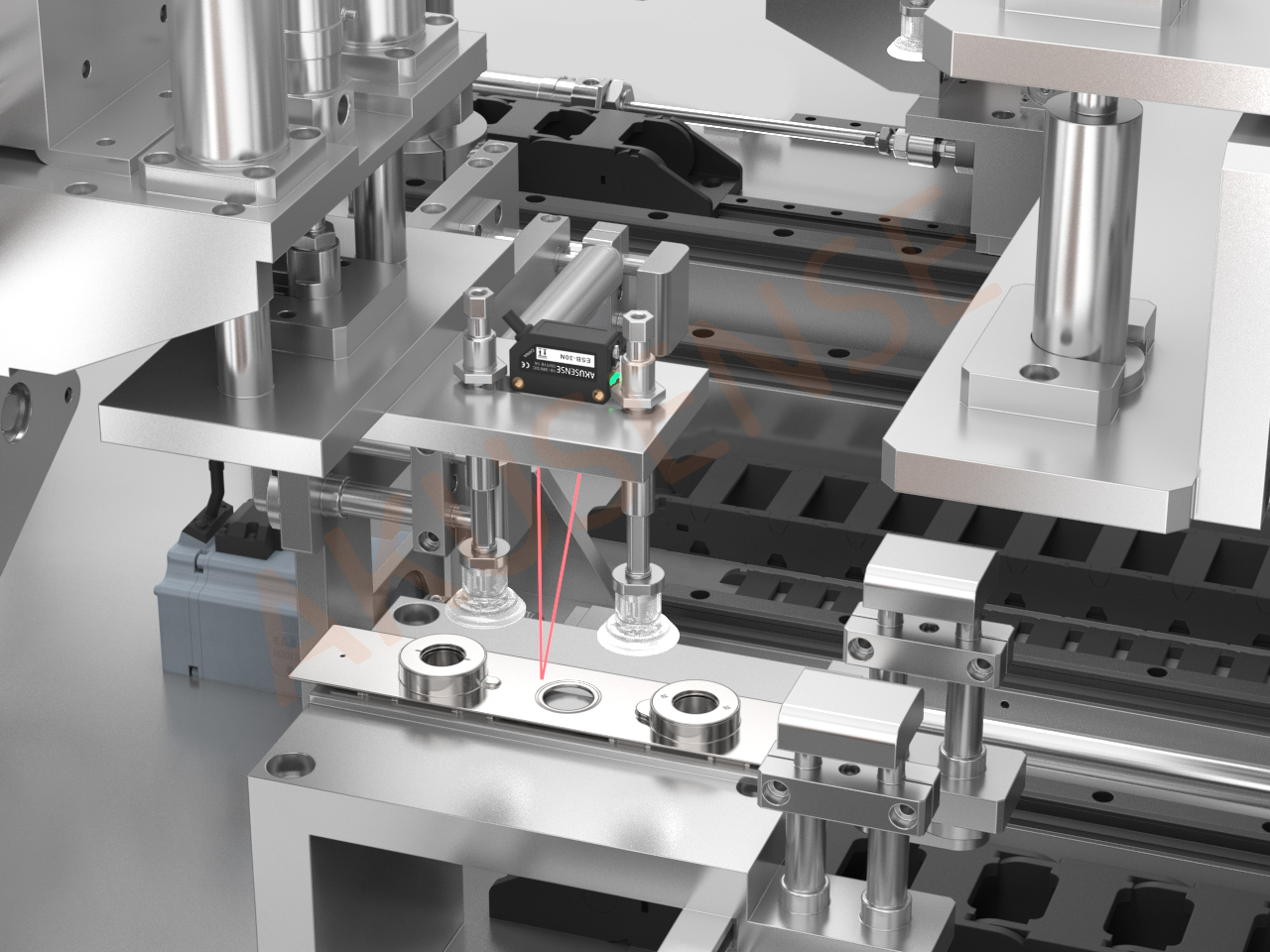

01 Battery cover material in place detection

Background suppression photoelectric ESB-30P

Application scenario:

The battery cover does not give a signal to the position sensor. When the cylinder moves down 10mm to absorb the battery cover, the sensor gives a signal and moves to the next station.

Solution:

1. The cover detection area is metal, highly reflective and with an uneven surface

2. The battery cover does not give a signal to the position sensor. When the cylinder moves down 10mm to absorb the battery cover, the sensor gives a signal. The accuracy of the detection distance is required. The detection distance must be reduced as much as possible to ensure stable detection

3. The material transmission speed of the production line is fast, about 5pcs per second, and the response speed is required to be within 100ms

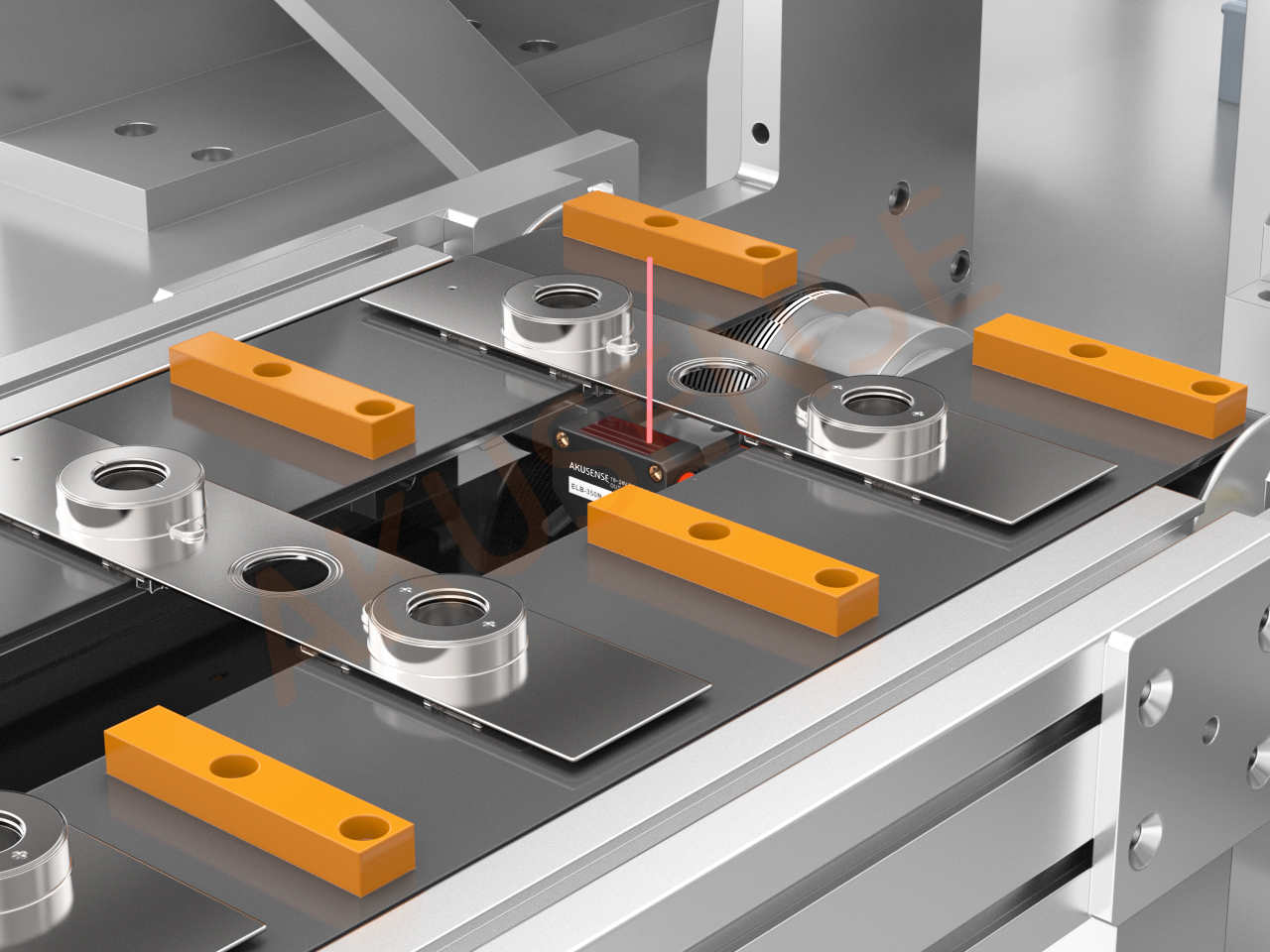

02 Detection of battery cover in the transmission channel

ELB-350P laser sensor

Application scenario:

It is necessary to detect whether there is a battery cover on the track to ensure that the trigger mechanism performs the next action when the battery cover is in place.

Solution:

1. The battery cover is a highly reflective aluminum surface, so you need to choose a sensor that is not affected by the background color, and the light spot should be as small as possible to avoid misjudgment

2. Laser sensor ELB-350P, laser light source, ultra-small light spot, the maximum diameter of the light spot is only 1.5mm, it is an ideal choice for long-distance detection of tiny objects

3. Built-in multi-turn potentiometer, can achieve fine adjustment of sensitivity

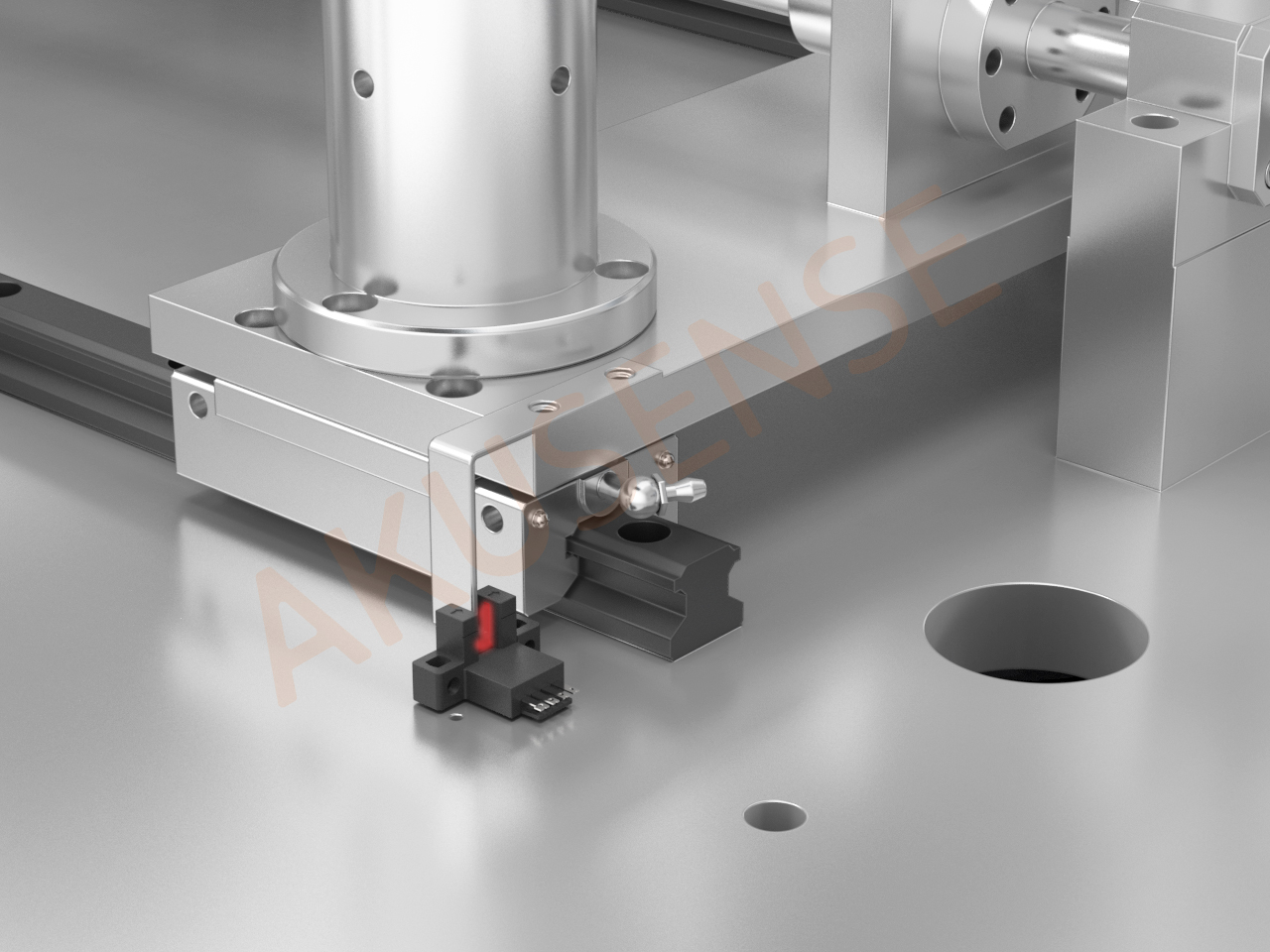

03 Stepper motor in place detection

Slot sensor SL-305PA-SE

Application scenario:

You need to select a sensor to send a signal to trigger the motor to stop and wait for the next movement after the induction motor is in place.

Solution:

1. Choose the preferred mechanical limit product slot photoelectric SL-305PA-SE, which has a high response frequency

2. Various shapes and installation methods

3. Principle of cross-beam detection, stable performance

04 Whether the cylinder is extended and retracted in place

Proximity sensor TLF12-04PO-E2

Application scenario:

A sensor is needed to detect whether the extension of the flip cylinder is in place. When the sensor senses the moving load, it sends a signal, and the upper cylinder presses down to shape the battery cover

Solution:

1. The cylinder moves back and forth at a fast speed and has a vibration effect. Therefore, it is necessary to choose an inductive proximity TLF12-04PO-E2 with high positioning accuracy, which has a surge absorption protection function and stable and reliable performance

2. The maximum switching frequency can reach 1000Hz, and it can still be stably detected in high-speed scenarios

3. Metal material, the appearance is not easy to wear and has a long service life

05 Whether the cylinder is extended and retracted in place

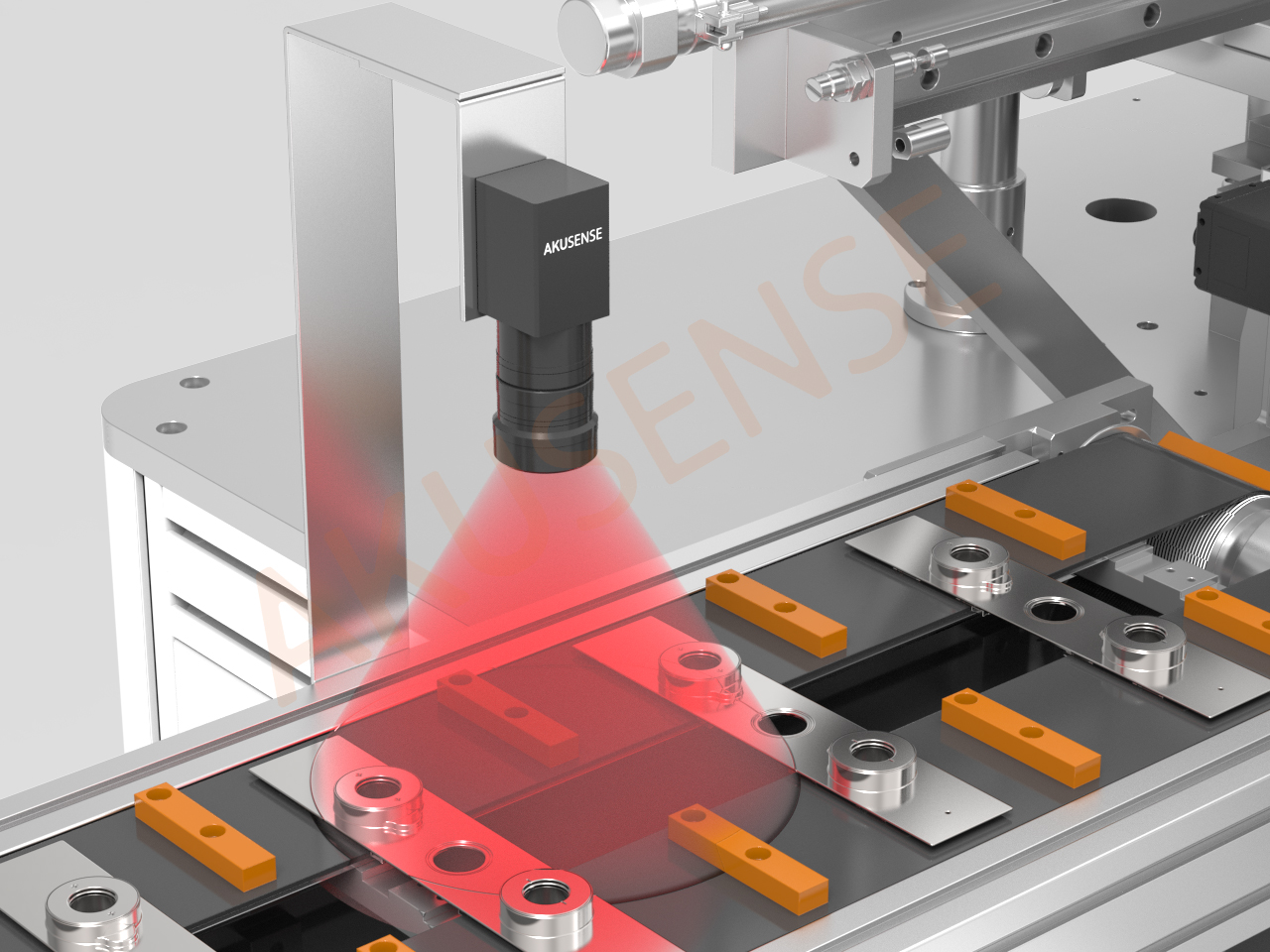

Customized visual inspection solution

Application scenario:

The processing of the cover requires special attention to ensure the processing accuracy and surface quality to avoid deformation, cracks and other problems. When the material is moving in the track, the visual system needs to inspect the material one by one for defects (including the front and back of the battery cover, color difference, deformation, crack defects, etc.)

Solution:

AKUSENSE tailors a visual customized camera solution to the project requirements to achieve full inspection. The front and back of the product, appearance defects, and color differences can be stably detected with an accuracy rate of 99.8%.

+86 18188641602