Syringe packaging equipment

Syringe packaging equipment

Go with health! Sensors assist fully automatic syringe packaging equipmentAs the last procedure in pharmaceutical production, pharmaceutical packaging is related to the quality assurance of drug storage, transportation, circulation and use.

In today's rapid development of automation, pharmaceutical packaging automation has become an inevitable trend. The use of automated control technology in pharmaceutical packaging not only helps to improve production efficiency and save labor costs, but also has extraordinary significance for product quality assurance, and sensors are also busy in automation equipment.

In this issue, let's share the application of AKUSENSE on automatic syringe packaging equipment~

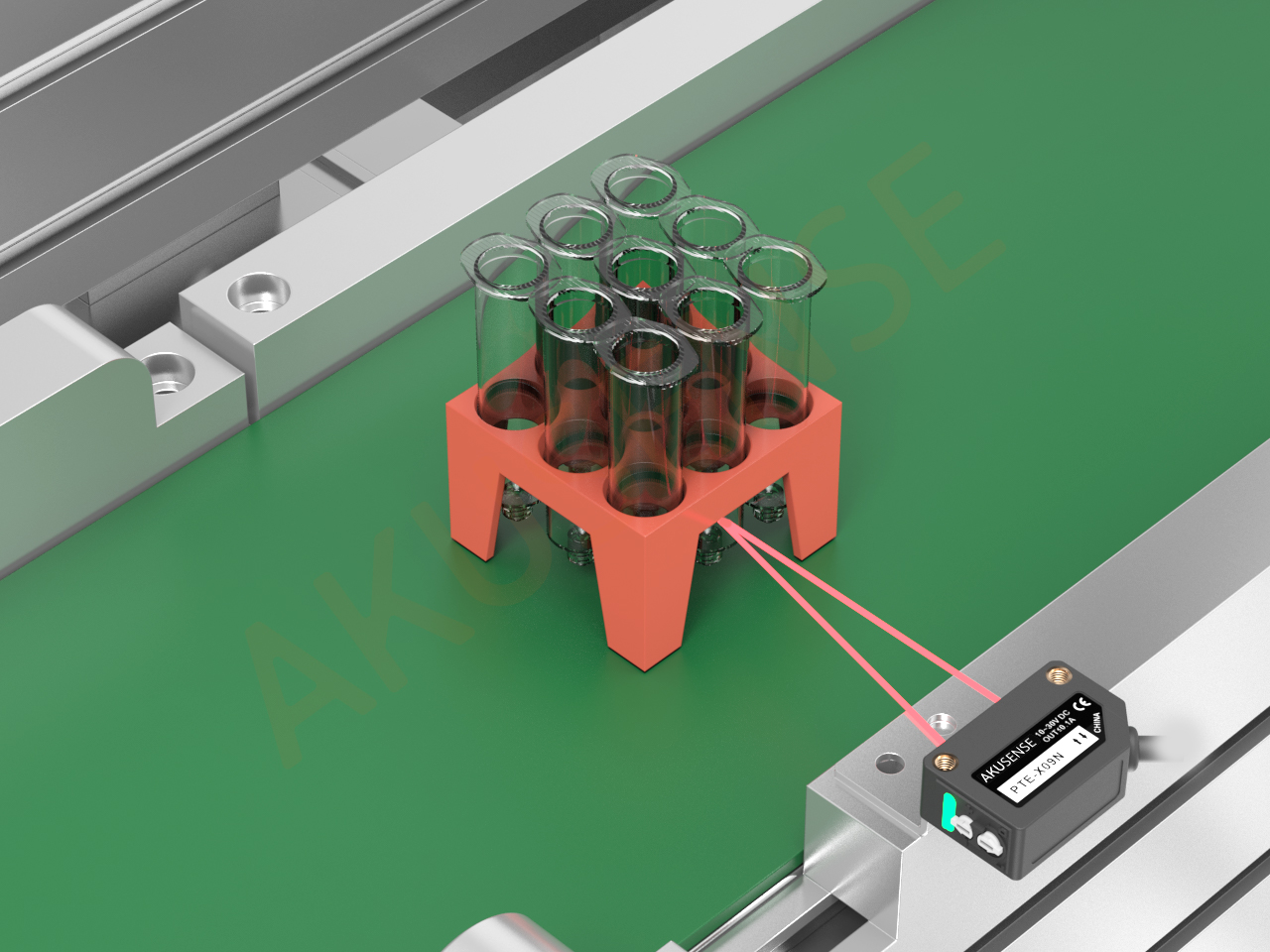

01 Syringe presence detection

Photoelectric sensor PTE-X09

Application scenario:

Whether there are syringe materials on the conveyor disc on the conveyor belt. The syringe is transparent and the detection distance is about 100mm. The detection speed is required to be stable within 1 second

Solution:

1. Use photoelectric sensor PTE-X09N to limit the reflection principle, so that the sensor is not easily affected by the color of the detected object, the gloss and tilt of the detected object, and has strong stability

2. The detection distance is 5-140mm, and objects at 100mm can be stably detected

3. The response time is less than 1ms, which can meet high-speed scene detection

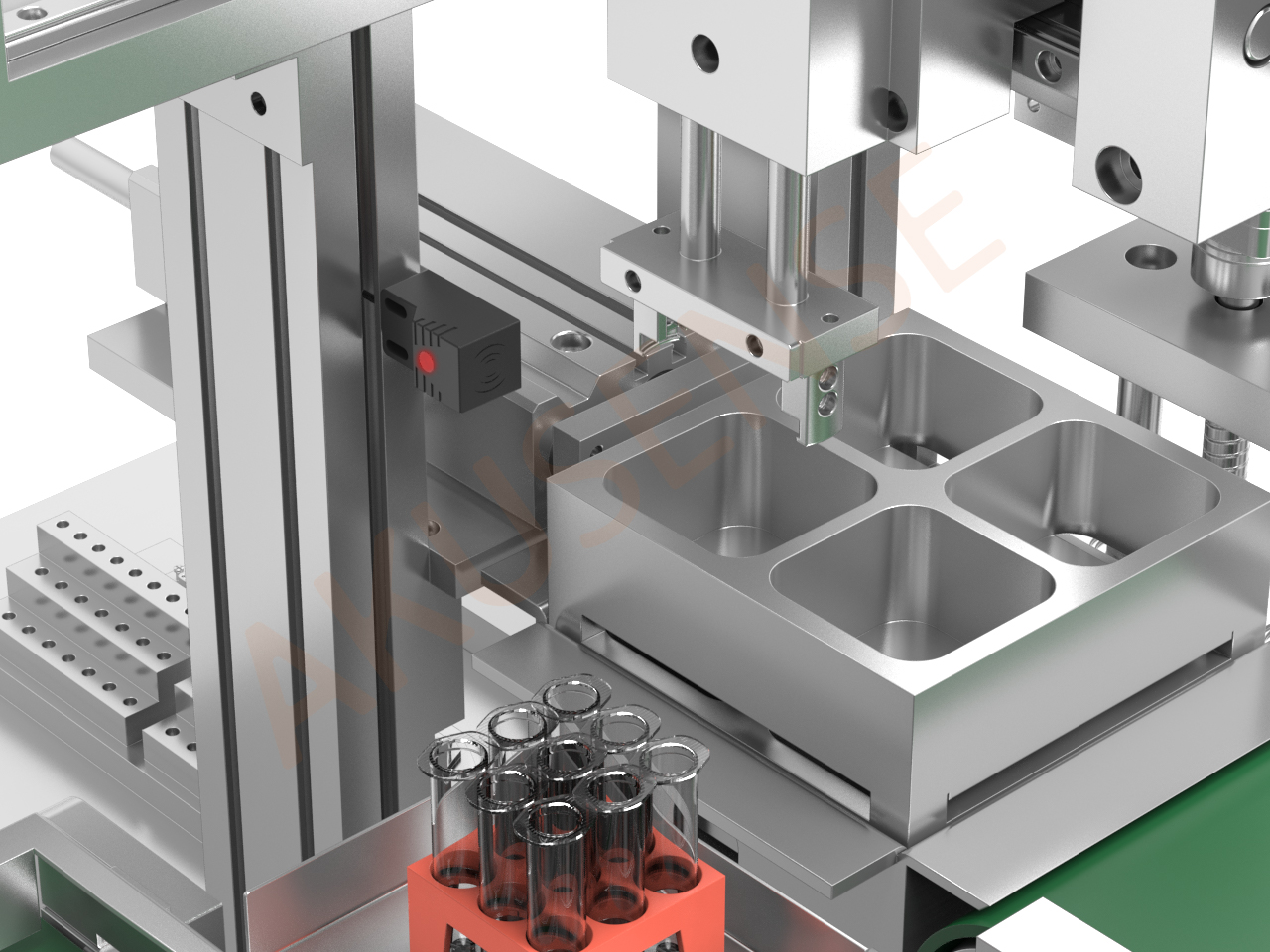

02 Detection of the arm position

Proximity sensor TQF18-05NO

Application scenario:

When the arm removes the syringe from the conveyor table/replaces it with another batch of syringes, a sensor is required to detect whether the final position of the arm is in place. The sensor's repeatability is required to be less than 0.5mm; the response is less than 2ms; it should be noted that there is a stepper motor next to the workstation, which will generate an electromagnetic field during operation and cause a certain degree of interference to the sensor

Solution

1. Use embedded inductive square proximity sensor TQF18-05NO to reliably detect metal swing arms

2. The repeatability is as high as 1%F.S, about 0.05mm, which can accurately avoid the situation where the swing arm position moves and causes incorrect up and down movements, resulting in material waste

3. The detection distance is 5mm; the response frequency is 1KHz, and the response time is less than 1ms, which can meet high-speed detection scenarios

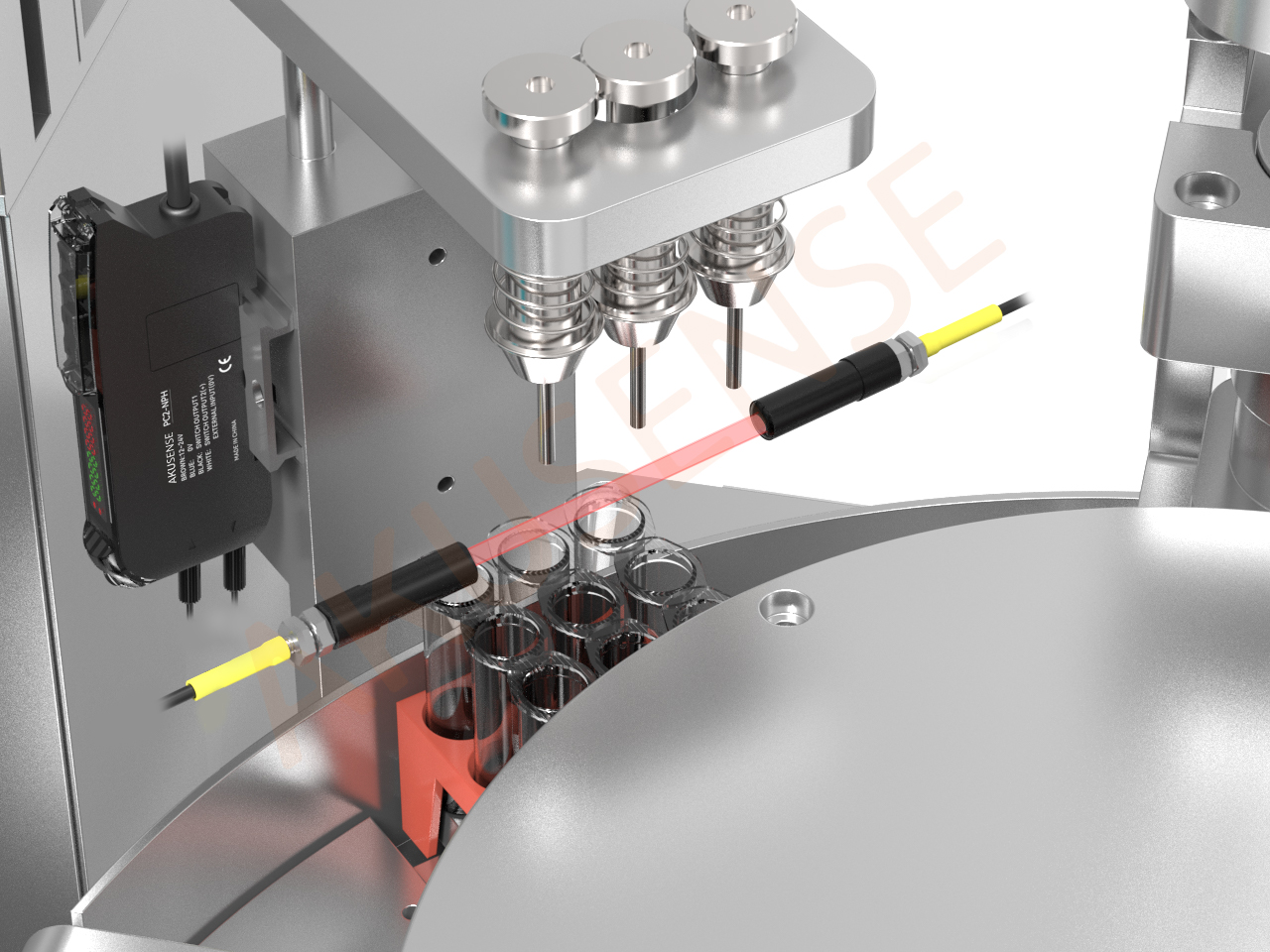

03 Blowing needle in place detection

Fiber optic sensor PC2+PT-32+PF-4T

Application scenario:

A sensor is needed to detect whether the blowing needle is in place. The needle size is small, only about 10mm, and it is required to be able to detect tiny objects; the production line speed material transmission speed is about 1 second 5pcs. The response speed is required to be within 100ms

Solution:

1. Use the fine beam of the optical fiber sensor to detect whether the blowing needle returns to its starting position correctly

2. The PC2-NPH amplifier accurately adjusts the parameters through the digital display, and the microsecond response speed supports the equipment to achieve high-speed and stable detection under mobile conditions

3. PC2-NPH has 7 gear adjustments, which can adapt to various detection needs; NPN/PNP output can be switched freely, easy to use

5. PT-32 is a beam-through optical fiber, used with the PF-4T focusing lens, which makes the light source more concentrated and easily realizes the detection of tiny objects

04 Level detection in the funnel

Proximity switch CKN12-06NO

Application scenario:

Here, the sensor is used to detect the material level in the plunger hopper: when the minimum signal is received, the system starts to add the plunger to the hopper, and stops feeding the hopper when the maximum signal is received. The sensor is required to be small and easy to install.

Solution:

1. Install a capacitive proximity switch CKN12-06NO at the highest and lowest positions installed at this station

2. M12 non-embedded type, adjustable detection distance 1-6mm, easy to install

3. Protection level is IP67, good dust and waterproof performance

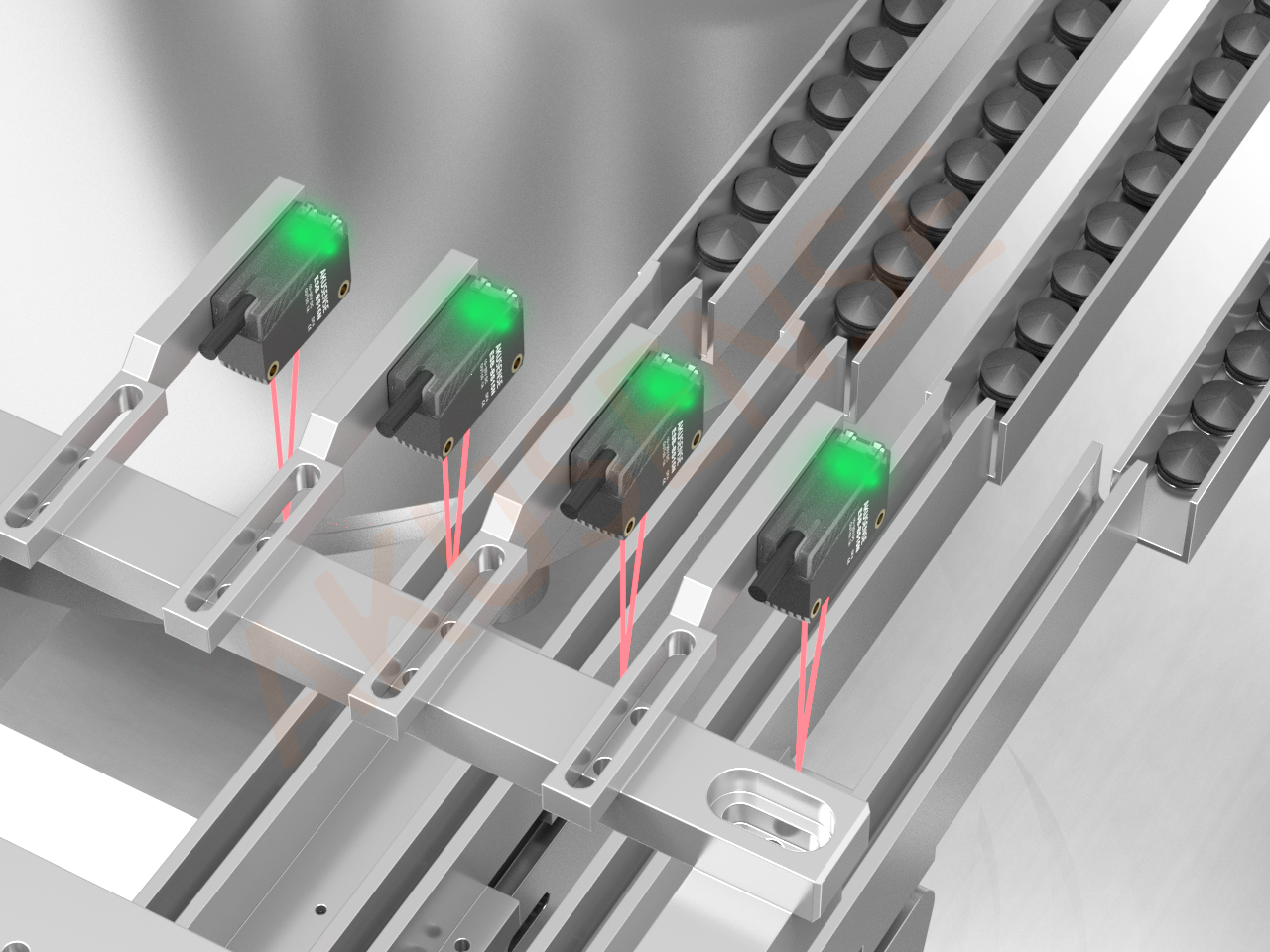

05 Black plunger detection

Background suppression photoelectric sensor ESB-BS15N

Application scenario:

The sensor is selected to monitor whether there is a black plunger in each feed channel. The sensor is required to be able to detect stably at a detection distance of 100mm; the response degree is required to be <1ms; the ambient light around this station is strong, and the sensor is required to be resistant to strong light

Solution:

1. Select the background suppression photoelectric sensor ESB-BS15N, which has a small light spot, high detection accuracy and strong stability

2. The detection distance is 150mm, and the detection distance can be adjusted by the top knob, which is easy to install and debug

3. The response time is <1ms , while ensuring stable detection, it has strong anti-light interference ability, can resist sunlight up to 10000Lux, and can resist incandescent lamp up to 3000Lux

06 Hatch door switch status monitoring

Safety door lock AR3-MBUA

Application scenario:

To detect the switch status of the hatch, the safety switch needs to have an independent actuator to prevent the hatch from being opened.

Solution:

1. Choose the safe and reliable Meiji safety door lock AR3-MBUA

2. With multiple certifications, including TUV, CCC, CE, SIL4

3. Built-in multi-contact structure is available, and the installation method and head installation direction can be selected

4. IP67 protection level, good waterproof and dustproof performance, and can be unaffected in harsh working environments

As the pharmaceutical market has increasingly stringent requirements for packaging, packaging technology needs to be continuously improved, and as a carrier of pharmaceutical packaging, pharmaceutical packaging equipment also needs to be continuously improved to meet the growing demand of the pharmaceutical packaging market; Meiji Sensing will also follow the needs of equipment manufacturers and match more efficient and applicable intelligent sensing solutions.

+86 18188641602