Semiconductor uniform glue developing machine

Semiconductor uniform glue developing machine

The role of the sensor in the glue leveling and developing machineSemiconductor leveling and developing machines generally consist of a power system, a developer tank and a spray pipe, a water washing tank, a squeeze (water) roller, a glue coating tank and other parts. It is suitable for semiconductors, chemical materials, silicon wafers, wafers, substrates, etc. Conductive glass and other processes, surface development of plate making.

In this issue, let’s share the role of the sensor in the glue leveling and developing machine~

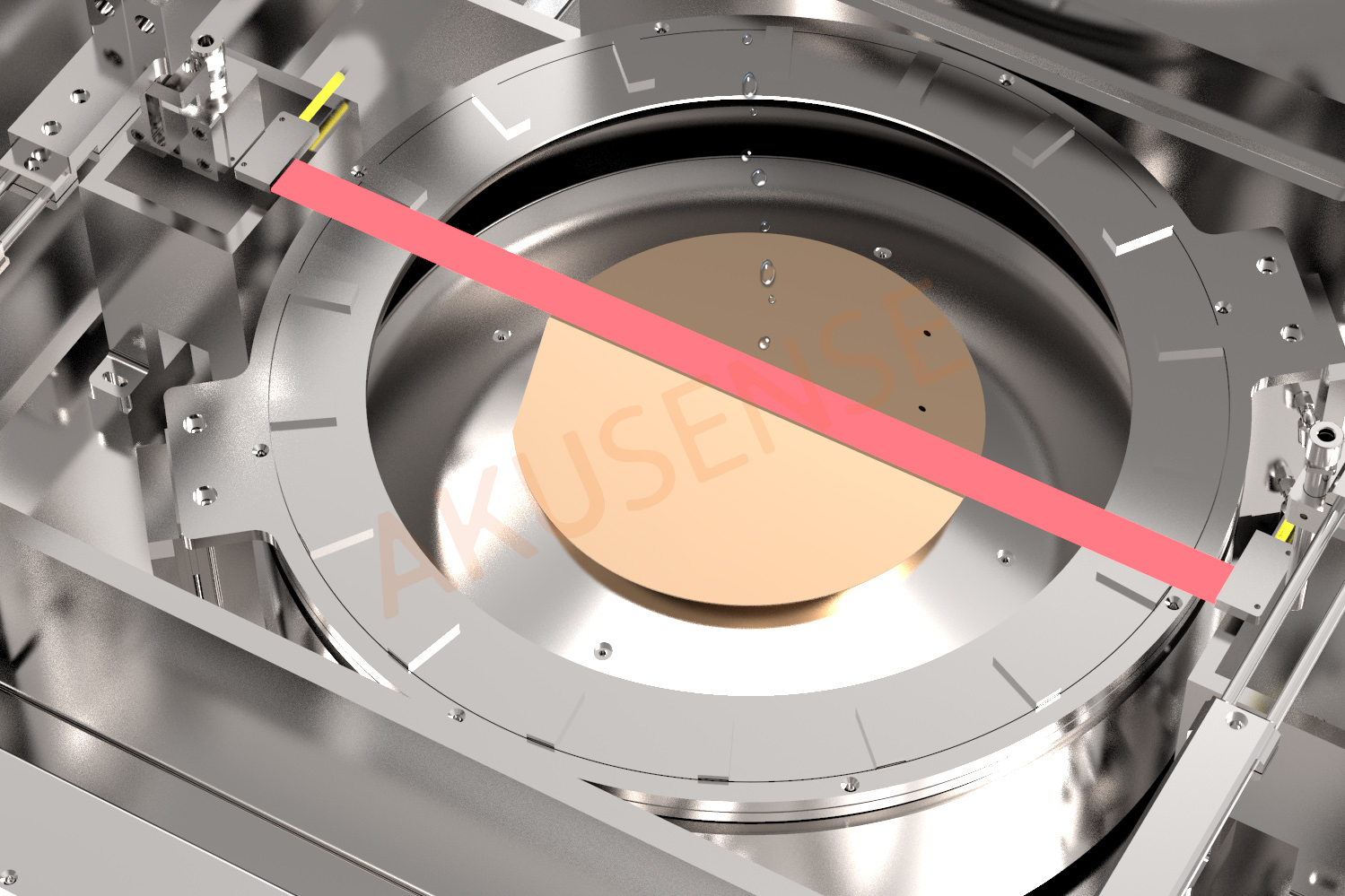

01 Detect water droplets/glue droplets

Fiber optic sensor PG1+ PT-30ML

1. The use of regional through-beam optical fiber covers a wide area. Even if there is a slight deviation in the path of the water droplet, it will still be within the detection area and can be stably detected.

2. High power, clear and bright optical axis, and the position of the optical axis can be easily adjusted

3. The amplifier is equipped with an ultra-high-speed mode and a microsecond-level response time, enabling stable and rapid detection.

4. SET button debugging, easy to use

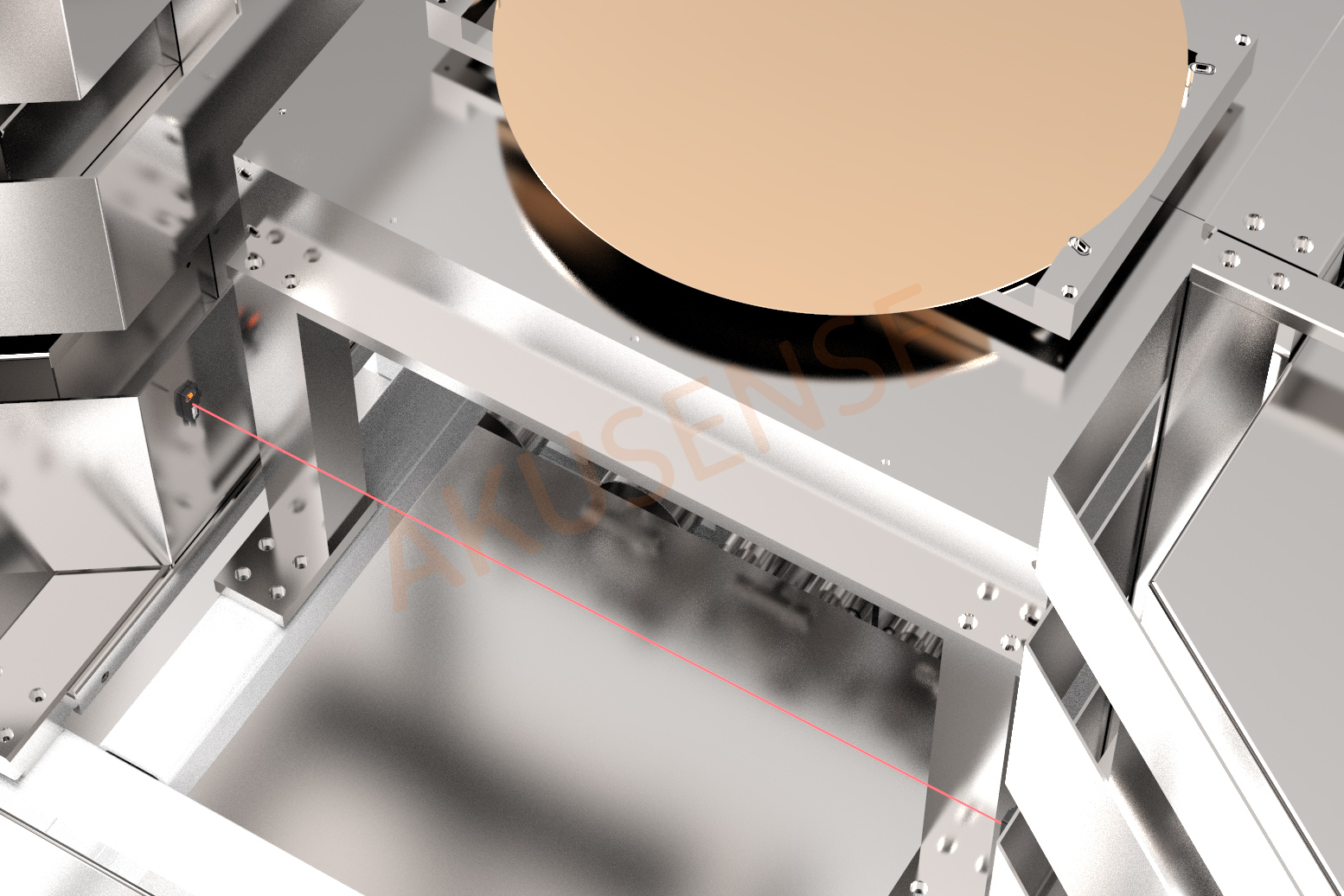

02 Detect chip position

Laser sensor ELE-RM05N

1. The light intensity value deviation caused by changes in the color and shape of the wafer transfer box is very small. It is necessary to select a retroreflective sensor for stable measurement and install a reflector to reduce wiring troubles.

2. The light spot is small, and the sensor can be installed on the outside, through the hole to detect internal materials, and easily identify the misalignment of the chip such as tilt/lack of material, etc.

3. The laser has good directivity, small spot, and is easy to install.

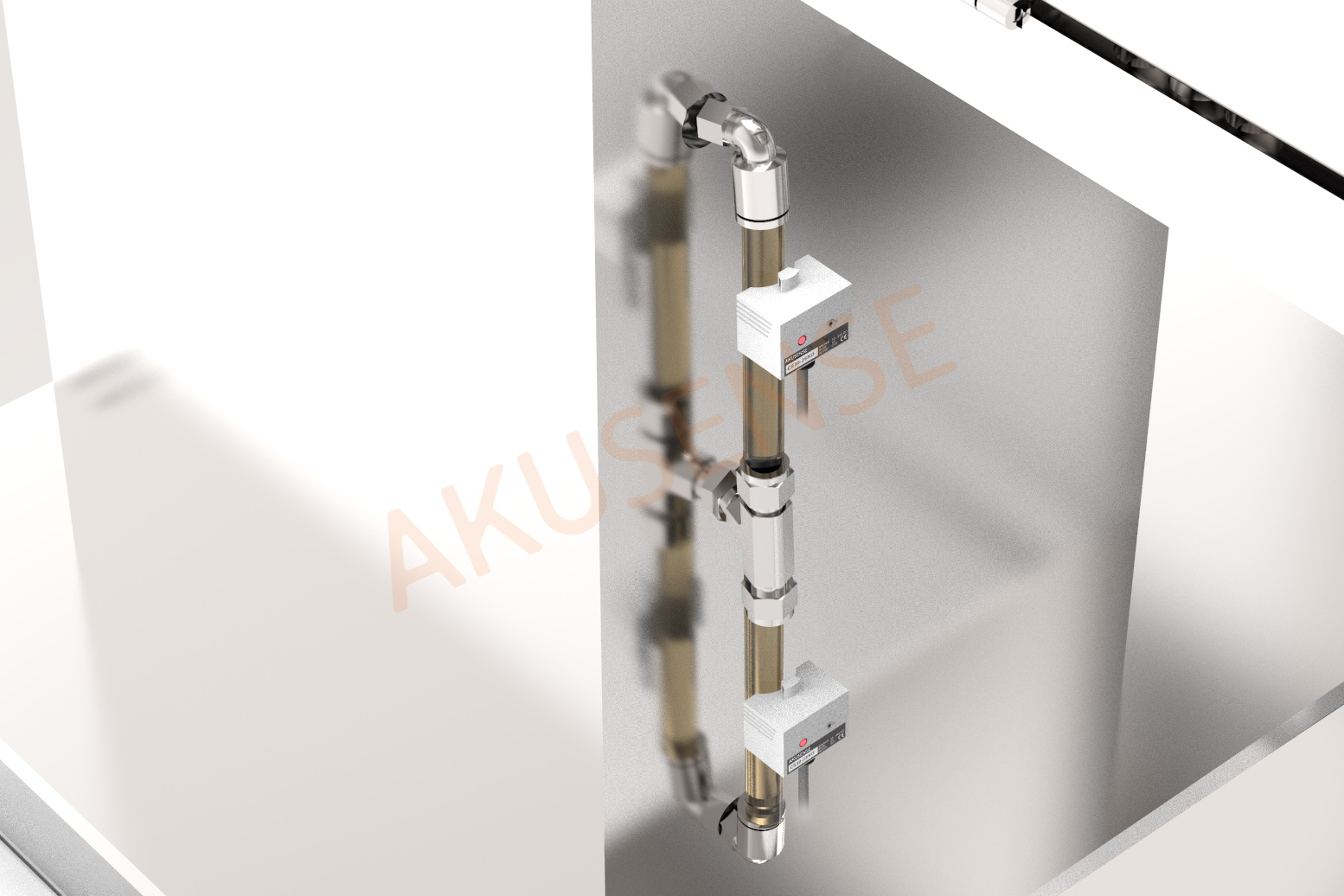

03 Control the hydrophobic liquid level

Liquid level sensor CE30-26NO

1. When there are bubbles in the grooved tube, ordinary optical sensors are likely to cause misjudgment.

2. Product protection level IP67, waterproof and dustproof

3. The sensor fixation method is flexible and the detection position can be easily moved at will.

04 Lower limit detection of cassette stage

Proximity sensor ESL-T50NO

1. Ultra-thin size, only 4mm thick, can be installed in any small space

2. Adopt through-beam detection principle, stable and reliable

3. The detection distance is up to 50cm, and can be used in equipment scenarios of any size.

+86 18188641602