Reagent filling machine

Reagent filling machine

To significantly reduce the cost of nuclear testing, just using these sensors is enoughSince the outbreak of the new coronavirus, "nucleic acid testing" has begun to appear repeatedly in our lives as an important indicator for detecting infection. As epidemic prevention and control continues to advance, there is still a large gap in the supply and demand of COVID-19 testing, and this demand may last for a long time. The nucleic acid reagent production environment has very high requirements for cleanliness. Dander, dust, settled bacteria, and floating bacteria must not exceed standards. Production materials must also be strictly processed in the buffer room before they can enter.

Faced with such huge demand and strict production standards, a large number of supporting automation equipment emerged at the historic moment. However, when manufacturers use early-stage equipment, they often encounter problems such as slow speed and low efficiency, and the inability to identify defective products. So I found Meiji to customize a complete set of equipment sensor solutions, hoping to help solve the pain points of the original equipment, thereby improving the efficiency and yield rate of the equipment to achieve the goal of reducing costs and increasing efficiency.

What is a nucleic acid reagent filling, sealing and labeling all-in-one machine?

The reagent filling machine belongs to the application field of liquid filling and capping machines. It is composed of a fully automatic bottle and cap unscrambler mechanism, a filling and capping machine, and a labeling machine. The degree of automation of production is greatly improved; by setting parameters such as filling volume in advance, the filling machine can realize automatic filling, capping, etc., thus reducing manual work positions and reducing production costs.

01 Test tube clamping jaw loading

Fiber optic sensor PG1+PD-E32

When loading transparent test tubes, it is necessary to detect whether there is any in the loading area to drive the gripper to pick up the material.

The installation distance here is relatively close, so the detection distance of the sensor does not need to be too far; considering the different materials of the test tubes and the convenience of transformation after the epidemic, it is recommended to choose optical fiber sensors with richer functions. Coupled with the adjustment of the mechanism, it not only replaces the previous workload of manual feeding, but also speeds up the speed of feeding. Manual feeding is 60 pieces per minute. After optimization, it not only replaces manual labor, but also increases the speed to at least 160 pieces per minute. .

①The optical fiber amplifier can adjust the sensor brightness threshold according to the different reflective amounts of different test tube materials.

②Adopt the through-beam working principle to make the detection effect more stable

③ This equipment has many moving mechanisms (servo motors and frequency converters will cause interference to the sensor). The fiber-optic sensor is of the optical transmission type. The amplifier and fiber head are installed in different positions. You only need to shield the amplifier to avoid unnecessary noise. Electromagnetic interference.

02 Status detection of clamping jaw cylinder, pushing cylinder, etc.

Cylinder sensor MR-C8-C-S

Test tube retrieval, bottle cap grabbing, and optional bottle cap cylinder clamping all require the use of cylinder sensors to provide feedback on the status of the cylinder switch to the control center PLC. The cylinder sensor MR-C8-C-S not only provides the real-time operating position of the cylinder, but also monitors the operating status of the sensor itself and the operating status of the pneumatic actuator in real time. The response speed is fast, reaching 5 microseconds.

03 Bottle cap loading

One to four optical fiber sensor PC1+PD-S4Q3-30

In order to increase efficiency, it is necessary to perform loading inspection on the four positions of the bottle caps coming out of the vibration plate at the same time, and to grab four bottle caps at the same time. But without increasing the cost too much, we chose this four-head optical fiber head and a higher-performance optical fiber amplifier. The principle is the same as that of test tube loading, but it saves the money of three sets of optical fiber sensors and the labor of the original work station. cost, and also greatly improves work efficiency and stability.

04 Virus preservation solution level monitoring

Liquid sensor CE15-13NO

A liquid sensor CE15-13NO is installed on the outer wall of the main pipeline at the back end of the peristaltic pump to monitor the presence of liquid. When there is no liquid in the pipeline, a signal is given to remind the equipment to shut down or alarm, and to add liquid to avoid sampling liquid without cans. Defective products flow away causing losses, and they have to be reworked.

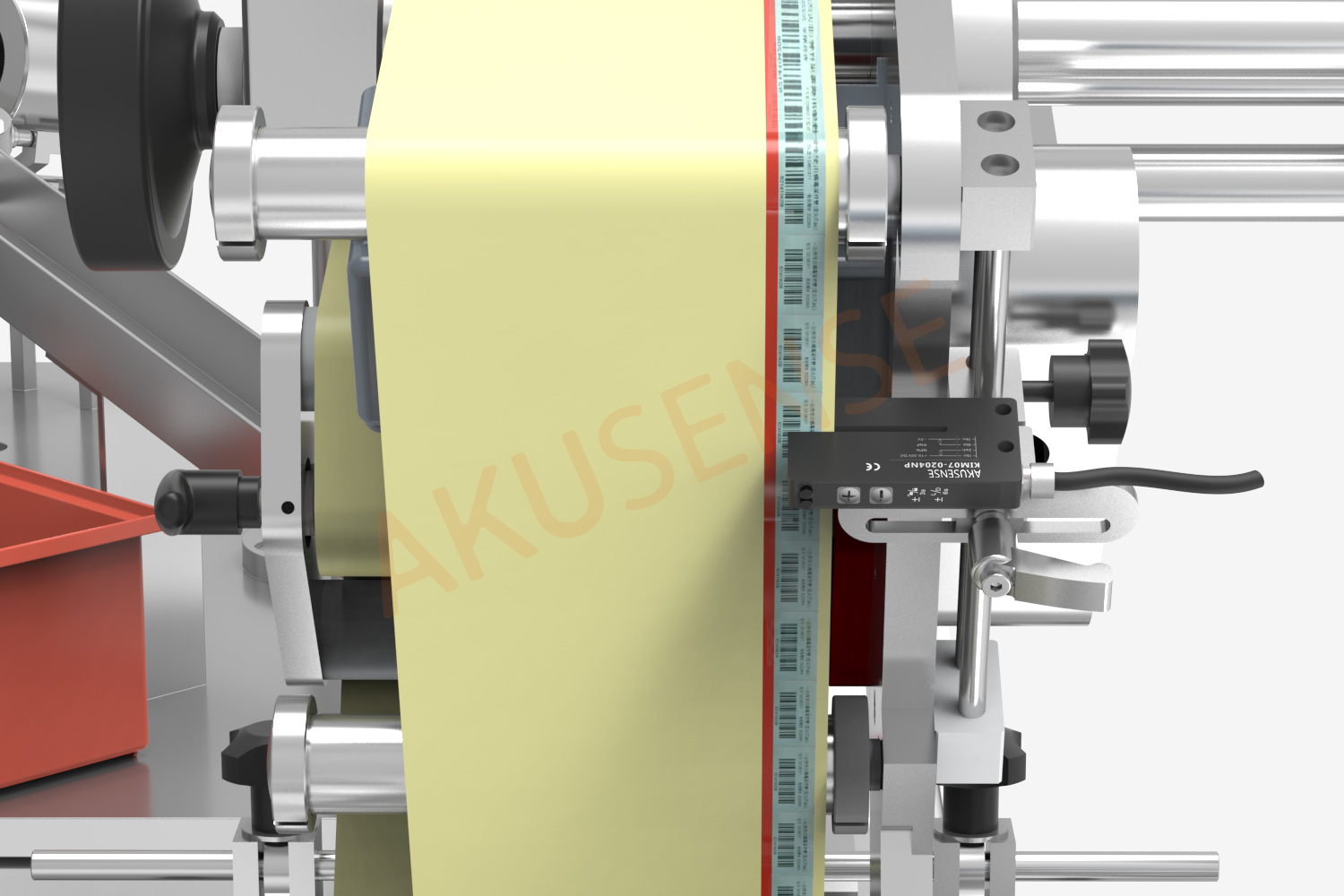

05 Reagent labeling

Tag sensor KIM07-0204NP

After the filling and capping stations, it is time to post the barcode, which is to give each reagent unique identity information so that the information can be traced when the nucleic acid results are issued. It turns out that the manufacturer arranged for an employee to manually label at this station. The optimization plan provided by Meiji was to use the label sensor KIM07-0204NP to cooperate with the roller mechanism to complete automatic labeling. At the gap between the two labels on the label paper, the sensor gives an action signal to stop rotating the label paper, and then continues to rotate after the previous one is attached. In this cycle, the purpose of automatic labeling is achieved, which not only saves the manpower of labeling It also reduces the cost and improves labeling efficiency several times.

06 Information storage and traceability

Intelligent code reader RCD-AI100-S

After labeling, the QR code needs to be read and stored. You only need to install the intelligent code reader RCD-AI100-S above the conveyor belt to automatically save the information into the system in real time to facilitate testing institutions or medical institutions to batch according to the requirements. Retrieving information from each test tube eliminates the need to search one by one, making it convenient and fast. This function also greatly enhances the competitiveness among similar types of equipment.

+86 18188641602