Production and packaging equipment

Production and packaging equipment

Application solutions on beverage production and packaging equipmentIn 2022, China's total social retail sales of beverages reached 302.1 billion yuan. Faced with such a large market demand, highly automated production lines are undoubtedly the guarantee of quality and production capacity;

Sensors, as the key core of the automation system, are widely used in smart packaging; Meiji Sensing provides customized equipment and smart sensing solution support for beverage packaging equipment manufacturers and consumer product manufacturers.

In this issue, Xiao Ming will share with you the application solutions of AKUSENSE in beverage production and packaging equipment~

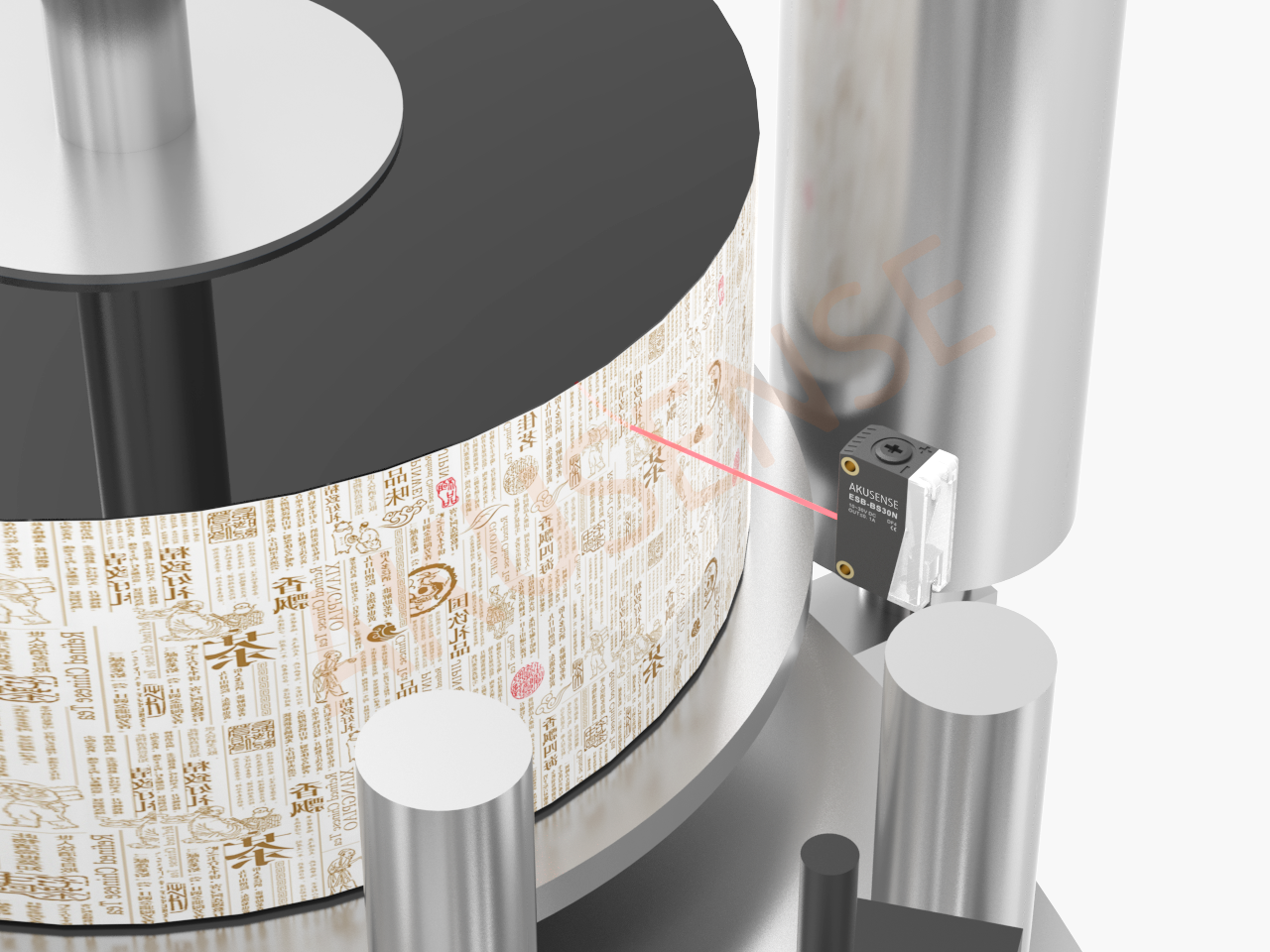

01 Label film input monitoring

Background suppression photoelectric ESB-BS30N

Application scenario:

During the transmission of packaging paper, a sensor is needed to monitor the status of the roll material, including warnings when the label film breaks and early warnings of insufficient roll material; to ensure timely response when the roll material breaks abnormally

Solution:

The background suppression photoelectric sensor ESB-BS30N is used to identify the presence or absence of the input film roll, and a signal is sent to remind the staff of abnormalities when the label film breaks

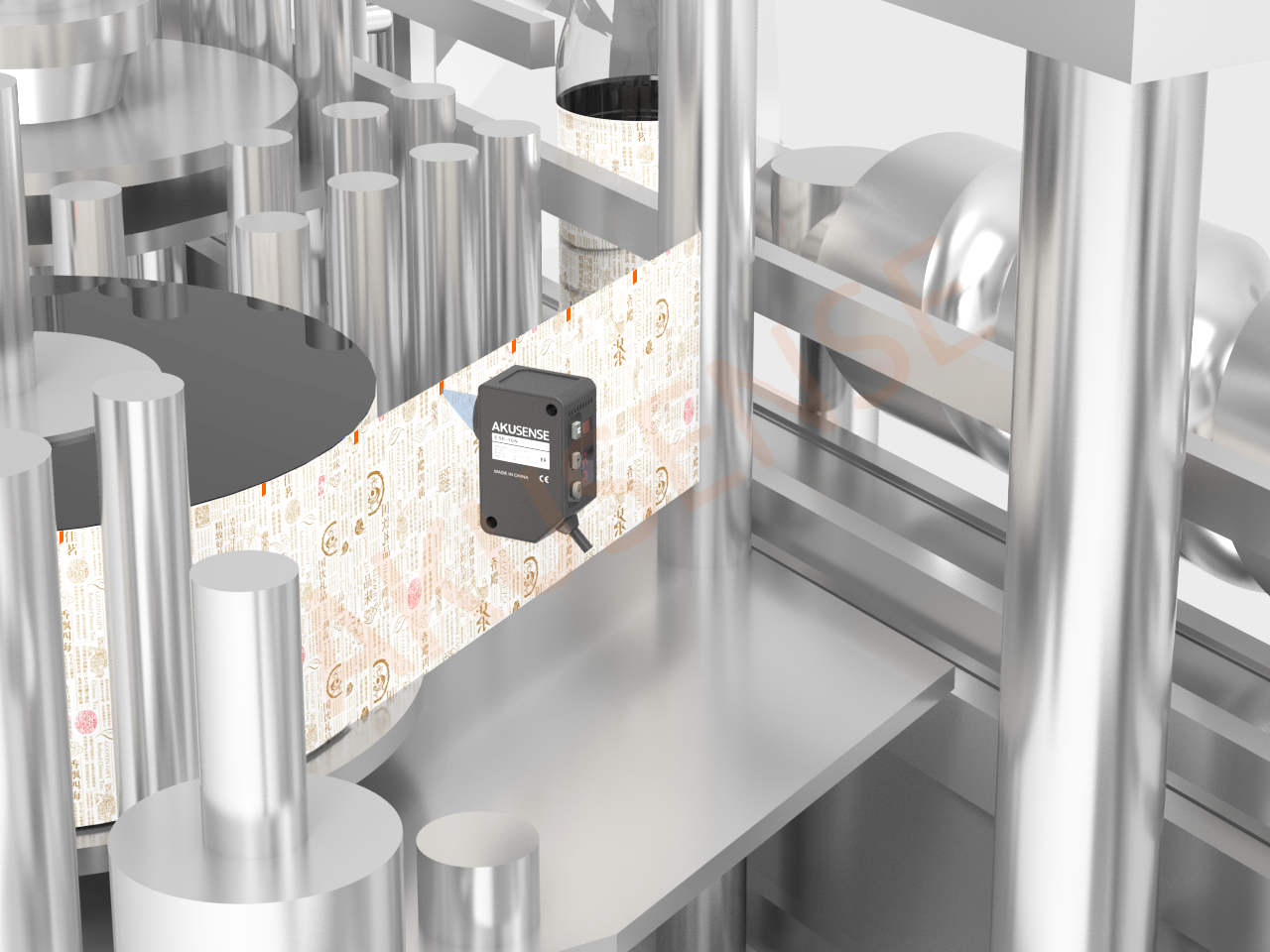

02 Label color mark recognition

ESE series color mark sensor

Application scenario:

It is necessary to use a sensor to detect the label color mark during the high-speed operation of the conveyor line to identify whether the label color is incorrect

Solution:

1. Use ESE series color mark sensors, color mode or color mark, two modes are optional, and the detection method is flexible and convenient

2. Fast response time, IP67 protection level

3. With the RGB light source self-selection function, dynamically adjust the light source color, and capture the product color characteristics simply and accurately

4. Even if the workpiece is tilted or the detection distance changes slightly, it can still detect stably

03 Bottle contour recognition

Line laser sensor ESX-I075

Application scenario:

When manufacturing bottles, various product deformations will be produced, and the cycle rate of the conveying process is high; in order to achieve fast and smooth transportation, it is necessary to reliably identify the shape of the bottle

Solution:

1. Using the line laser sensor ESX-I075 to accurately identify the shape and surface of the packaging bottle

2. Analog output can determine what material the bottle is made of

3. It can support various materials, suppress the influence of multiple reflections, diffuse reflections, etc., and show a stable shape

4. Simple debugging, no complex detection settings and programming are required to complete the measurement and detection

5. It can match complex transparent object detection without installing reflectors

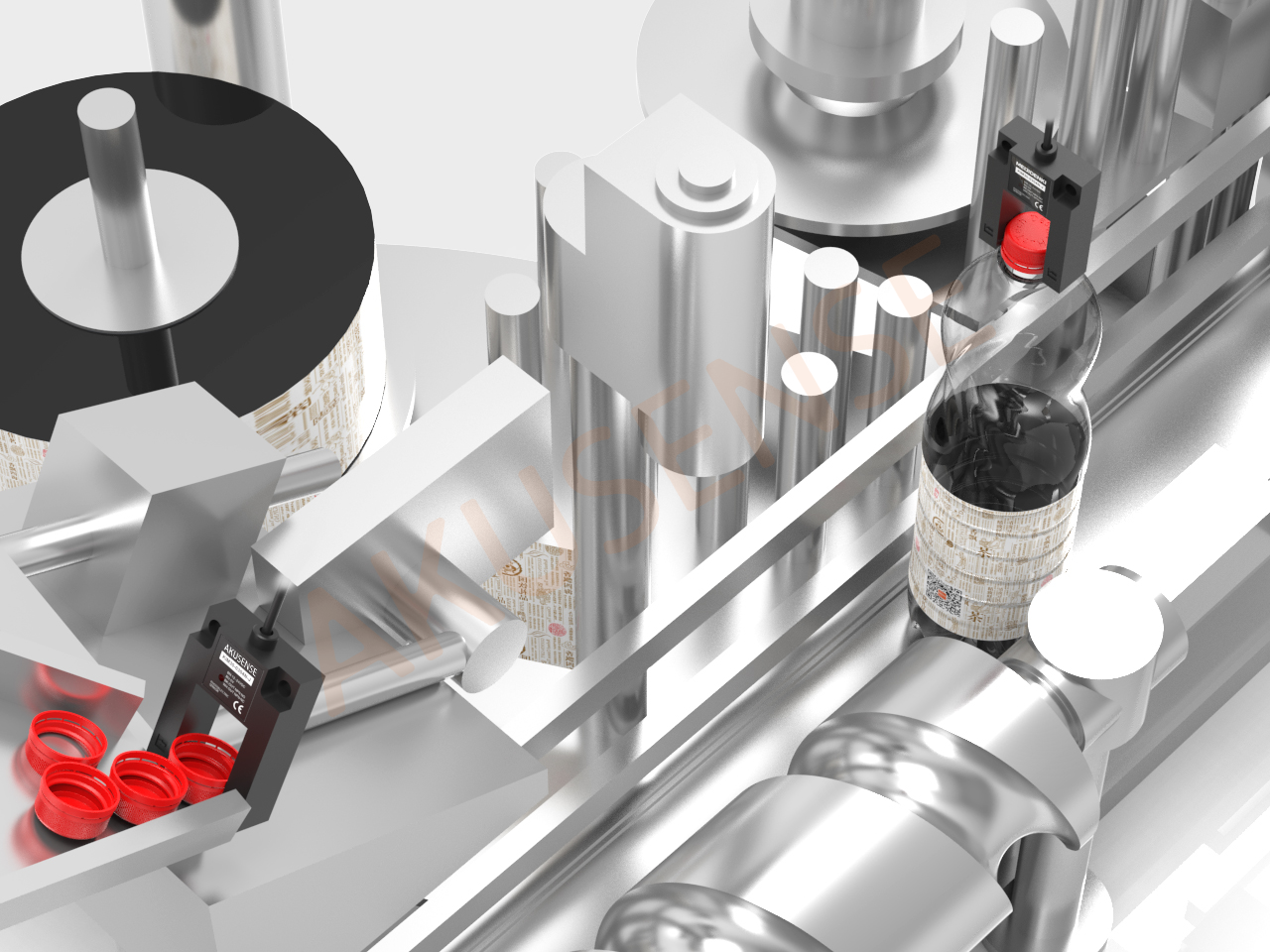

04 Bottle cap positioning

Slot sensor KIM30-0304P

Application scenario:

To ensure that the bottle caps are in place before the bottle is sealed and tightened, a sensor is needed to confirm the presence of materials

Solution:

1. Use two wide slot sensors KIM30 series. The first one checks whether the bottle caps in the input area exist and are in the correct position. The second sensor checks whether the bottle caps are correctly located on the bottle

2. The 30mm wide slot KIM30-0304P sensor can effectively prevent the elevator from hitting the sensor due to the narrow slot and causing damage

3. The sensor response speed is ≤1ms, with strong anti-interference performance, which can support high-speed operation of the equipment and achieve capacity improvement

4. It can detect opaque objects larger than ф2mm, with strong anti-interference performance, which can support high-speed operation of the equipment and effectively improve production capacity

05 Is the bottle cap tightened?

Customized visual inspection solution

Application scenario:

It is necessary to check whether each filled bottle is reliably capped to avoid unnecessary losses caused by product leakage

Solution:

1. The visual inspection solution can check the placement and tightening position of any bottle cap used and identify tightening errors; it can easily configure the conversion between different bottle caps

2. The high-speed presence or absence detection capability of this visual sensor enables the equipment to perform repetitive work at high speed, high accuracy, long-term and stable, greatly improving product quality and production speed

3. In addition, it can easily complete tasks under harsh environmental conditions, ensuring the unmanned hygiene requirements of food packaging

06 Bottle QR code data reading

Intelligent code reader RCD-AI100-X16RD

Application scenario:

Each beverage can on the production line is given an "identity card", which runs through the supply chain and is constantly identified and stored. It not only plays a key role in identifying, recalling, or withdrawing when there are quality problems with the product, but also is a tool for consumers to obtain accurate product information.

Difficulties in detection:

1. Most beverage bottles have arc-shaped surfaces, and the speed of the production line increases the difficulty of code reader recognition

2. The QR codes of canned beverages are mostly marked on the bottom of metal bottles, using laser engraving technology, and are small in size, requiring normal recognition in a high-reflective environment

Solution:

1. Select the intelligent code reader RCD-AI100-X16RD, one-click parameter adjustment, and convenient operation

2. The megapixel image sensor, combined with advanced sampling technology and deep learning algorithms, has a millisecond decoding speed and a recognition accuracy of up to 0.02mm, and can support ultra-small codes (one-dimensional barcodes with a minimum of 0.03mm; two-dimensional codes with a minimum of 0.02mm)

3. It has red, white, and polarized light sources, supports code reading with different background colors, and is compatible with light and dark scenes and multi-product height differences at the same time, with strong scene compatibility

4. Optional polarized light source, through angle adjustment and the filtering effect of the polarizer, most of the background stray light can be filtered out, and the QR code on the surface of highly reflective materials can also be easily read.

Beverages are products that are popular among current consumer groups, are repurchased frequently, and are sold for a long time. Reducing costs and increasing efficiency through industrialized production is the key to improving the competitiveness of companies. I believe that with the joint efforts of all parties, we can bring more high-quality beverages to consumers and help companies incubate more brands that are famous at home and abroad.

+86 18188641602