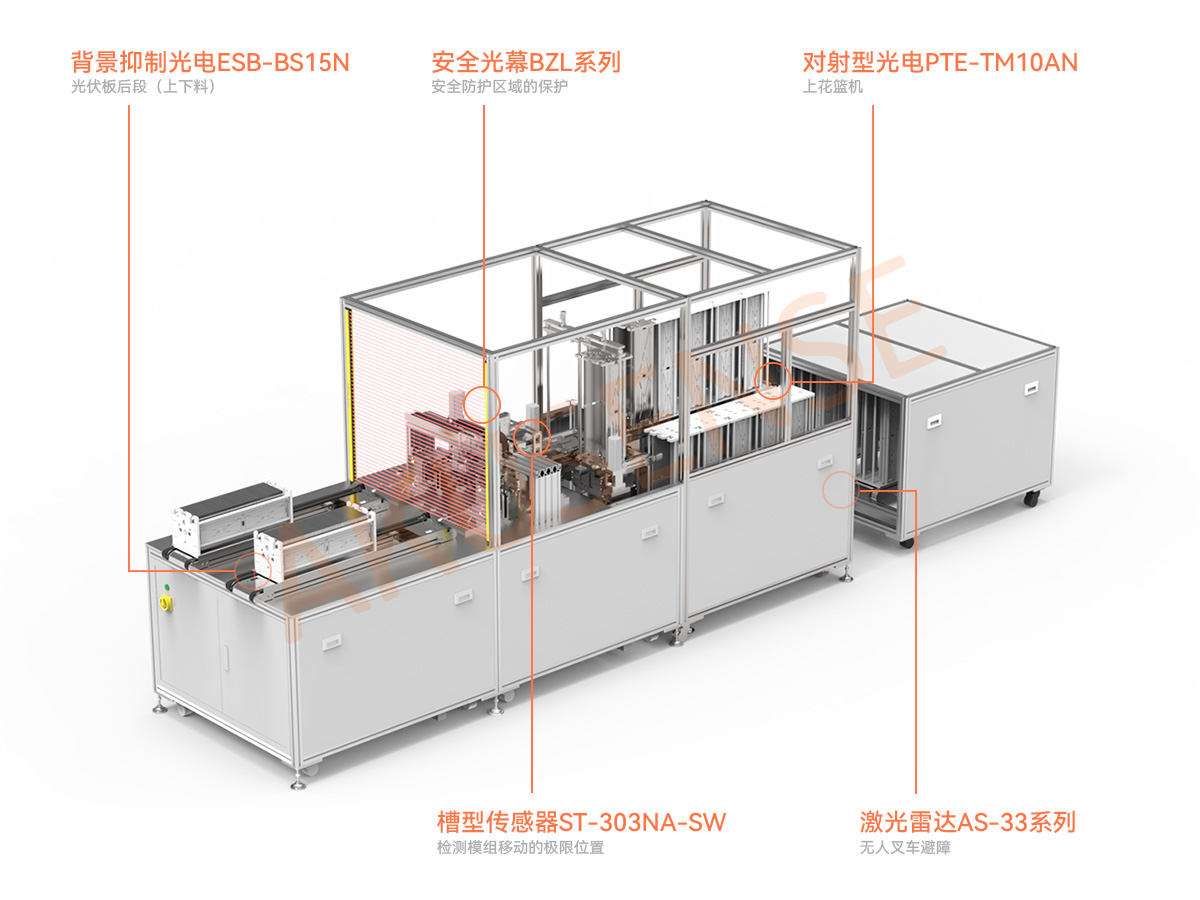

Photovoltaic typesetting

Photovoltaic typesetting

Behind trillions of growth, the secrets of photovoltaic industry workshopsPhotovoltaics is one of the hottest and most involved fields at the moment. In March 2022, the global cumulative installed photovoltaic capacity easily exceeded the 1,000GW mark, officially entering the "terawatt era." Among them, China accounts for more than 1/3. At present, all links in China's photovoltaic industry chain have been localized, the supply chain has achieved independent self-control, and photovoltaic cell conversion efficiency has set new world records many times.

The rapid growth indicates that China's photovoltaic industry has once again reached the forefront of the industry through the wave of "carbon neutrality" and technological innovation.

The secrets of technological innovation and process innovation are hidden in the workshop

The photovoltaic industry chain includes six links: silicon material, rods, slices, cells, battery components, panels, and application systems.

After more than ten years of development, the automated production of the entire photovoltaic module industry chain has become relatively mature. The photovoltaic module automated production line automates the entire photovoltaic module production process, which is completed by a combination of various operating units, and can realize the automation of the entire photovoltaic module process after loading.

Among them, the process of assembling solar cell units into a whole panel and making it able to withstand harsh usage conditions for many years is not only extremely demanding, but also requires a lot of manpower. To help reduce these costs, manufacturers are increasingly using robots to automate operations.

The photovoltaic typesetting machine that robots place battery strings on glass has the five characteristics of "high precision, high speed, high stability, large inertia without jitter, and greater professionalism", which greatly improves production efficiency and precision. In this issue, I will share with you [AKUSENSE’s solution for photovoltaic typesetting robots].

01 Flower basket machine

Through-beam photoelectric sensor PTE-TM10 series

Scenario requirements: This station is located before the shingle welding process for loading.

Application difficulties: The object to be measured is a photovoltaic flower basket with colors such as black, dark blue, milky white, light yellow, etc., which requires high sensor detection stability; and the line production speed is extremely fast, about 100mm/s, once the detection is unstable or missed , will cause greater losses and place higher requirements on the response speed of the sensor.

solution:

1. The photoelectric sensor using the through-beam detection principle ensures detection stability from the detection principle and meets the detection stability requirements of this station;

2. The detection distance of the sensor can be up to 10 meters, which is completely satisfactory in this scenario. The detection distance is adjustable, and installation and debugging are very convenient;

3. The sensor has a response time of 3.3ms and has the ability to accurately detect during high-speed movement. It is very suitable for this high-speed operation station;

4. The product adopts high-quality modulated light source, which will not produce obvious light attenuation phenomenon even if it is used for a long time, which can protect the long-term stable operation of the equipment;

5. The product has strong anti-light interference ability. Sunlight exposure can reach 10,000lux, and incandescent lamp exposure can reach 3,000lux. When the equipment is running at night, it can still detect stably if there is interference from lighting.

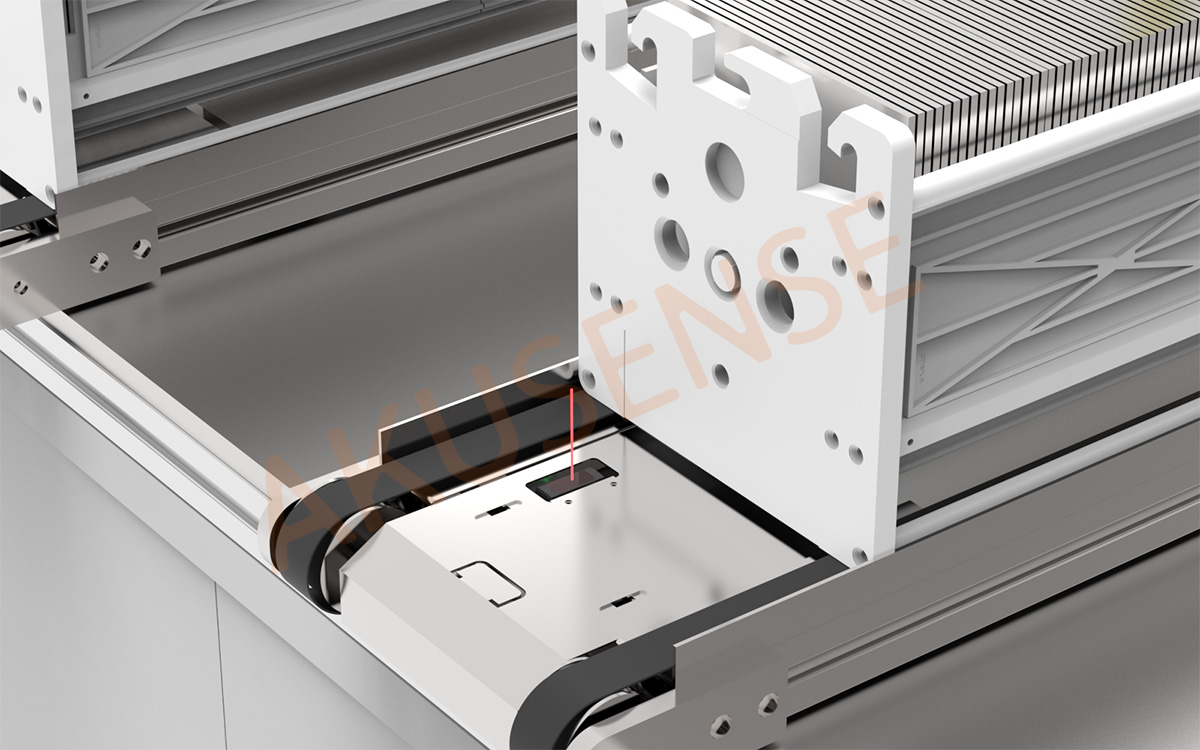

02 Mechanism module limit

Slot sensor ST-303 series

Scenario requirements: Detecting the extreme position of module movement, requiring high repeatability

solution:

1. The sensor adopts chip integrated design with high repeatability, up to 0.01mm, and can accurately detect the moving position of the module;

2. 3KHz high-speed response, 0.03ms response, hard core to help the equipment operate efficiently;

3. The product line is rich, with 12 shapes such as F/T/K to choose from, and multiple output mode indicators for free selection.

03 Regional security protection

Safety light curtain BZL series

Scenario requirements: Prevent people entering the workshop from accidentally entering the equipment working area and being injured. It is strictly forbidden to extend fingers into this area.

solution:

1. Use BZL series thin safety light curtains, with a cross-sectional area of 17.2*30mm, smaller in size than ordinary light curtains, and easy to install;

2. A variety of optical axis spacing and optical axis number are available. The optical axis spacing includes 10mm, 14mm, 20mm, 25mm, 30mm, and 40mm. The minimum detection object is 10mm for fingers and 20mm for palms;

3. Millisecond-level response time. When a foreign object invades the protected area, the sensor sends an alarm signal to the machine to drive the machine to stop, thereby avoiding injuries to workshop personnel and interference to equipment operation.

04 Unmanned forklift safely avoids obstacles

Laser Sensor AS-33C Series

Scenario requirements: To avoid obstacles and prevent collisions with vehicles passing in the aisle, the detection distance is 2 meters.

Detection difficulties:

1. Adapt to the needs of loading and unloading forklifts for various equipment

2. The operating space of unmanned forklifts is compact, and the radar size also needs to be smaller and more precise.

3. Need to adapt to work scenarios where humans and machines are mixed and multiple vehicles are mixed.

4. Measure distance accurately in real time to ensure the safety of forklift operation path

solution:

1. Use the laser obstacle avoidance radar AS-33C series to set the area that needs protection and give alarm signals (attention, early warning, alarm). The software clearly displays the information of people and objects within the detection range;

2. TOF measurement principle, accurately measure the 270° range of the device. When the reflectivity is 70%, the distance can be detected up to 10 meters, and when the reflectivity is 10%, the distance can be detected up to 4 meters, meeting the customer's detection distance requirements;

3. It has equipment self-test function and abnormal alarm function. The self-test function can detect whether there is any abnormality in the lidar itself, and the abnormal alarm function can detect the surrounding environment.

05 Photovoltaic panel rear section (loading and unloading)

Background suppression type photoelectric ESB-BS15 series

Scenario requirements: This station is located in the photovoltaic back-end process and requires sensors to position the photovoltaic panels on and off.

Detection difficulties:

1. The detection object is a silicon wafer. The sensor is installed vertically facing upwards. The detection distance is 70mm. There is an LED lighting above the device, which will cause light interference to the sensor;

2. During the operation of the equipment, due to high-speed movement, the material will vibrate slightly. The sensor is required to still be able to accurately identify the silicon wafer and quickly trigger the signal to the host computer. The response time is required to be less than 1ms;

3. This station has high requirements for detection accuracy, and the repeatability is required to be less than 0.5mm.

4. This equipment produces many types of silicon wafers (including high-gloss surfaces, dark blue, dark gray and other processed surfaces) and requires a sensor that can be compatible with the detection of all products.

solution:

1. It adopts background suppression photoelectric, which is not affected by any color and can ensure the stability of the sensor positioning for all types of materials;

2. The detection distance reaches 150mm, and the detection distance is adjustable through the top knob, making installation and debugging easy;

3. The response time is less than 1ms, which can ensure stable detection while ensuring detection efficiency. The small light spot has high detection accuracy;

4. The sensor has strong anti-light interference ability, and the sunlight exposure can reach 10,000lux, and the incandescent lamp exposure can reach 3,000lux, which can better solve the problem of strong ambient light around the target workstation and reflection of the silicon wafer itself.

+86 18188641602