Application of Sensors in Photovoltaic EVA Film Cutting Equipment for Safety and Precision

Application of Sensors in Photovoltaic EVA Film Cutting Equipment for Safety and Precision

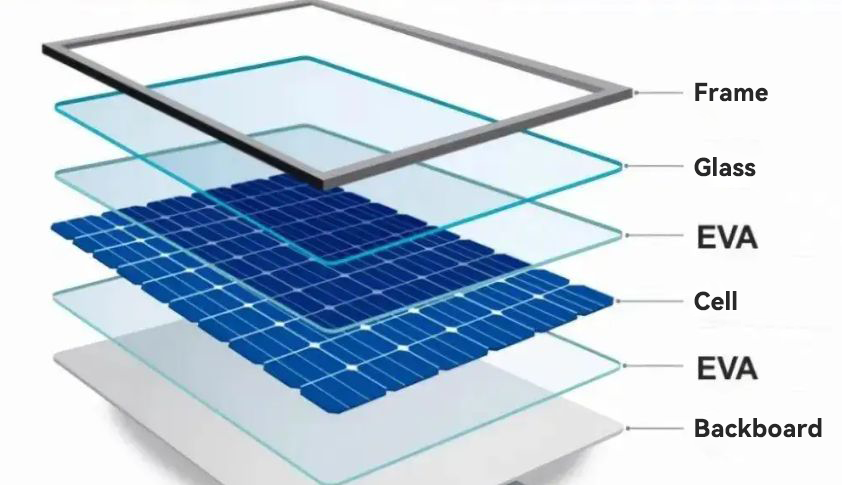

Application of Sensors in Photovoltaic EVA Film Cutting Equipment for Safety and PrecisionPhotovoltaic film is the core auxiliary material of photovoltaic modules. It covers the upper and lower surfaces of the cells, and is combined with auxiliary materials such as photovoltaic glass backsheets in a vacuum environment to form photovoltaic modules through a lamination process. It mainly plays the role of protecting the buffer of the cells and effectively extending the service life of the modules. The typical photovoltaic module structure from top to bottom is tempered glass → optical film → cells → optical film → transparent backsheet or tempered glass.

Among them, the photovoltaic cutting machine photovoltaic EVA film cutting machine provides important support for the production of the photovoltaic industry with its high precision, high efficiency and automation characteristics.

Taking the EV film cutting production line of a photovoltaic company as an example, the cutting accuracy of the production line has been significantly improved through the introduction of high-precision sensor technology. The sensor can monitor the position and speed of the membrane material in real time to ensure the accuracy and efficiency of cutting.

At the same time, through the application of pressure sensors, the production line also achieves precise control of cutting pressure, effectively extending the service life of the tool and reducing the damage rate of the membrane material. These improvements not only improve product quality, but also reduce production costs, bringing significant economic benefits to the company. In this issue, we will share the application of AKUSENSE sensors on photovoltaic EVA cutting machines.

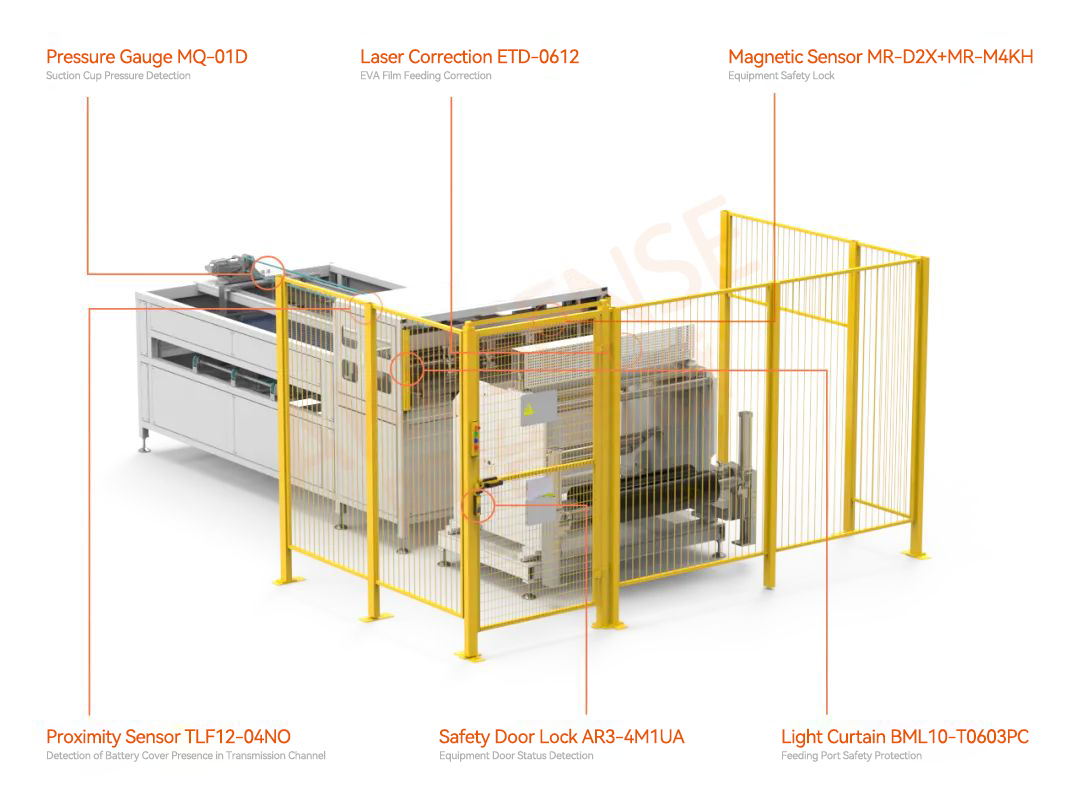

01 EVA film feeding correction

Precision laser correction sensor ETD-0612 series

Application scenarios:

During the loading process of the EVA film, deviation may occur during the transmission process. The deviation may cause cutting deviation and cause unnecessary losses. Therefore, it is necessary to install sensors to detect whether the deviation during the transmission process of the EVA film is within the range.

1. The accuracy of the sensor is required to be within 0.1mm

2. The conveyor belt is fast and requires a fast sensor response.

3. Need high stability to avoid waste of raw materials

solution:

1. Use AKUSENSE laser correction ETD-0612 series with a controller, the accuracy can reach up to 1um, and can complete high-precision correction control

2. Adopting the principle of laser beam measurement, it has ultra-high stability

3. The sensor responds extremely quickly and can easily cope with moving scenes.

4. Paired with a controller, parameter adjustment is easier

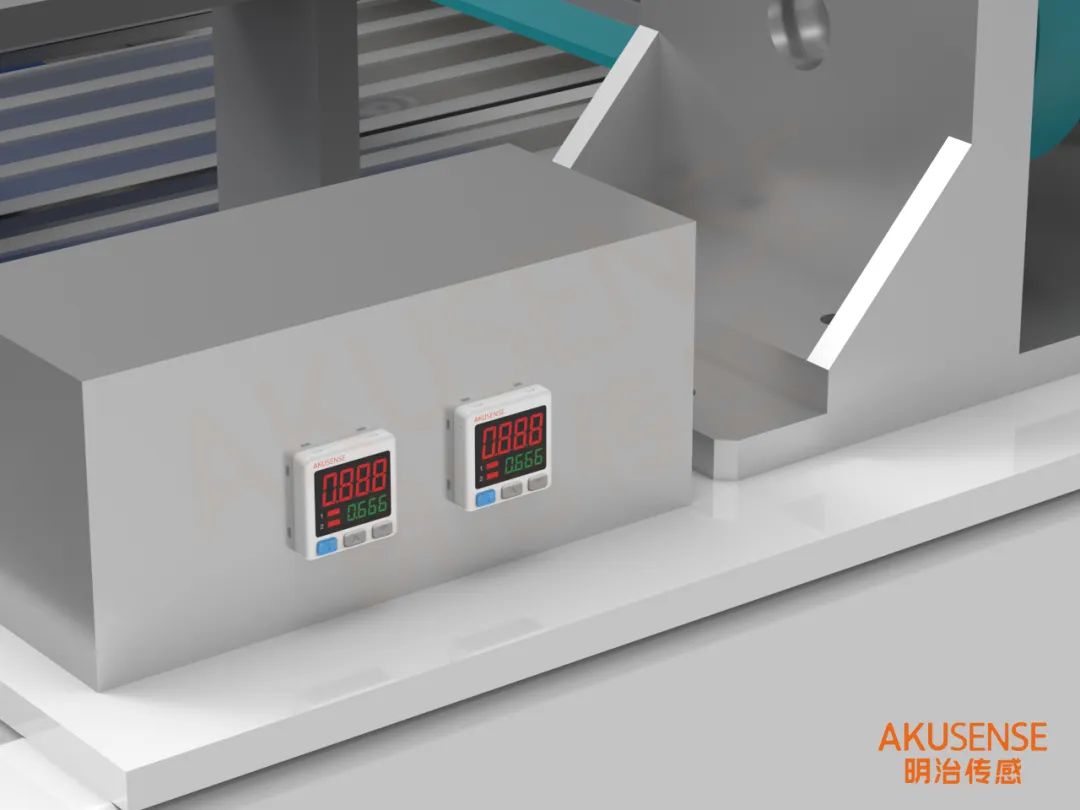

02 Suction cup pressure detection

Digital barometer MQ-01D

Application scenarios:

After the EV film is cut, it reaches the designated position through the conveyor belt, and then is grabbed onto the component by a robot.

Here it is necessary to detect whether the negative vacuum pressure of the suction cup of the grabbing module is within the set range. The sensor is required to stably monitor the pressure range of the equipment, with accurate repeatability and response speed.

solution

1. Choose AKUSENSE digital display pressure sensor MQ-01D. The sensor has undergone more than 2000W pressure impact tests and output signal reliability tests before leaving the factory, and its service life is guaranteed.

2. The sensor response speed reaches 1ms, exceeding all pressure gauges of the same type on the market, and the repeatability accuracy is ±0.2%, which is the same as that of well-known Japanese brands.

3. The sensor is equipped with an analog module inside, which can output analog voltage & current, making it more convenient to use.

4. Standard MODBUS protocol supports remote reading and real-time monitoring of setting operations.

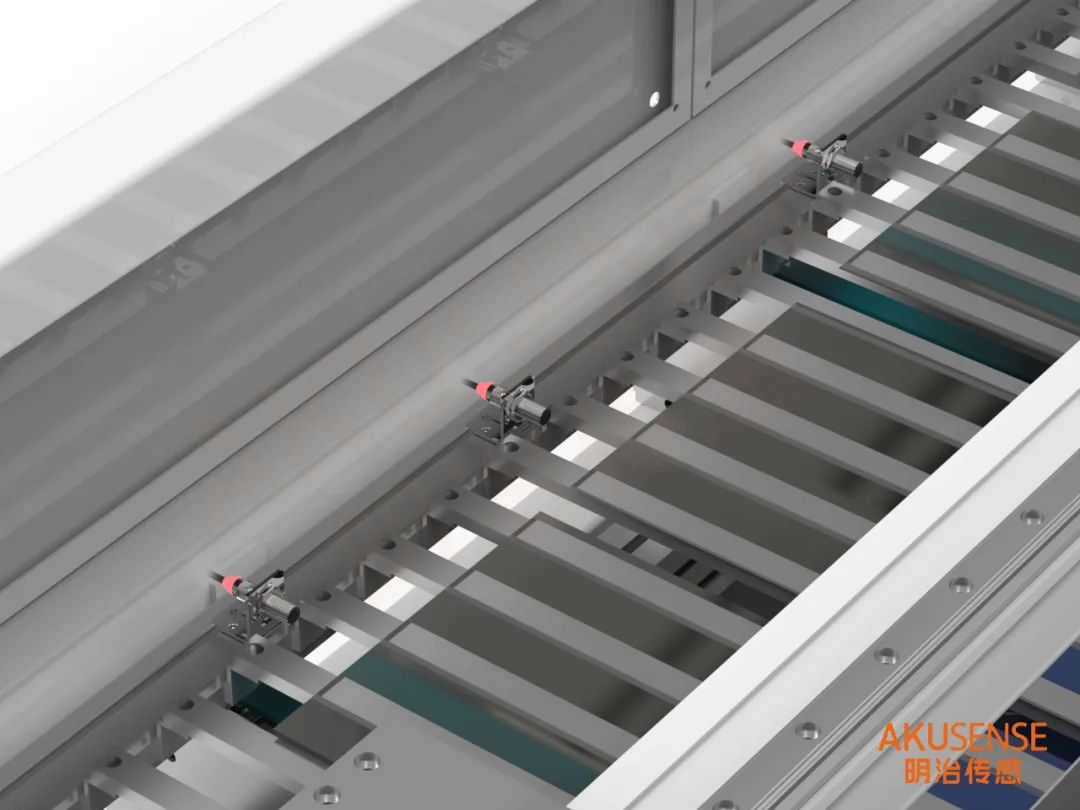

03 Lift height positioning

Proximity sensor TLF12-04NO

Application scenarios:

After the EV film in the conveyor line reaches the position, the product is transported to the empty cabin for backup. Sensors are required to detect whether the conveyor line has reached the position;

It is required that the sensor will not be affected by electromagnetic interference caused by the surrounding servo; and the conveyor line mechanism is made of stainless steel, so the detection distance of the sensor must not be affected by the material.

solution:

1. Use AKUSENSE proximity switch TLF series, with a repeatability accuracy of 5% of the detection distance.

2. Inductive proximity switch, detection distance is 4mm

3. The detection method is non-contact and will not wear or damage the detection object.

4. The protection level is IP67, with excellent water and oil resistance.

04 Equipment security door lock

Security door lock AR3-4M1UA

Application scenarios:

At the outlet of the cutting machine, a safety door lock needs to be installed to ensure that the equipment stops working when the safety door is opened to avoid unnecessary losses.

solution:

1. Choose AR3 series safety door locks, which are designed with PM66 flame-retardant material and can still operate stably in usage scenarios of -10℃-55℃.

2. The sensor has a long service life and has been tested for 100W plug-and-pull times. The internal hardware is precision designed and the forced pull-out force when locked is 1300N.

3. The sensor protection level is IP67 high protection level, which can meet various scenarios and working environments.

4. Certified by multiple testing agencies, the use effect and lifespan are guaranteed.

05 Equipment door status detection

Magnetic sensor MR-D2X+MR-M4KH

Application scenarios:

Install a sensor to detect the opening and closing status of the equipment door to protect the operator's safety. When the equipment door is opened, the sensor sends a signal to drive the equipment to stop running immediately.

solution:

1. Choose AKUSENSE magnetic sensor MR series, which has a fastening structure design, stronger shock resistance and long service life.

2. A variety of appearance sizes, heights, and inspection methods are optional, and can be customized according to the needs of various non-standard scenarios.

06 Safety protection of feed port

Safety light curtain BML10-T0603PC

Application scenarios:

1. On the feed port of the cutting machine, the EVA film passes through the feed port and enters the inside of the machine for cutting; sensors need to be installed here to prevent personnel from entering the work area and protect personnel safety.

2. The distance between optical axes needs to be short to prevent finger injuries.

solution:

1. Choose AKUSENSE standard safety grating BML series, which can detect objects with a minimum diameter of 14mm. Even if your fingers extend into the area, they can be quickly detected.

2. Response time ≦15ms. Once an object enters, a signal can be sent immediately to drive the device to stop moving.

3. Strong anti-light interference ability, can withstand up to 10000Lux sunlight interference, and is not affected by incandescent lamps and other stray light above the equipment

+86 18188641602