Create "silk" level precision to help PCB dispensing machine equipment strive for excellence

Create "silk" level precision to help PCB dispensing machine equipment strive for excellence

The dispensing machine equipment is an automated equipment that specializes in controlling fluid and dripping and coating the fluid inside the product.The dispensing machine equipment is an automated equipment that specializes in controlling fluid and dripping and coating the fluid inside the product.

In the PCB production process, a variety of parts need to be bonded and packaged on the PCB board. The fully automatic dispensing machine plays an irreplaceable and important role. In this issue, we will share the use of sensors on PCB dispensing equipment. application.

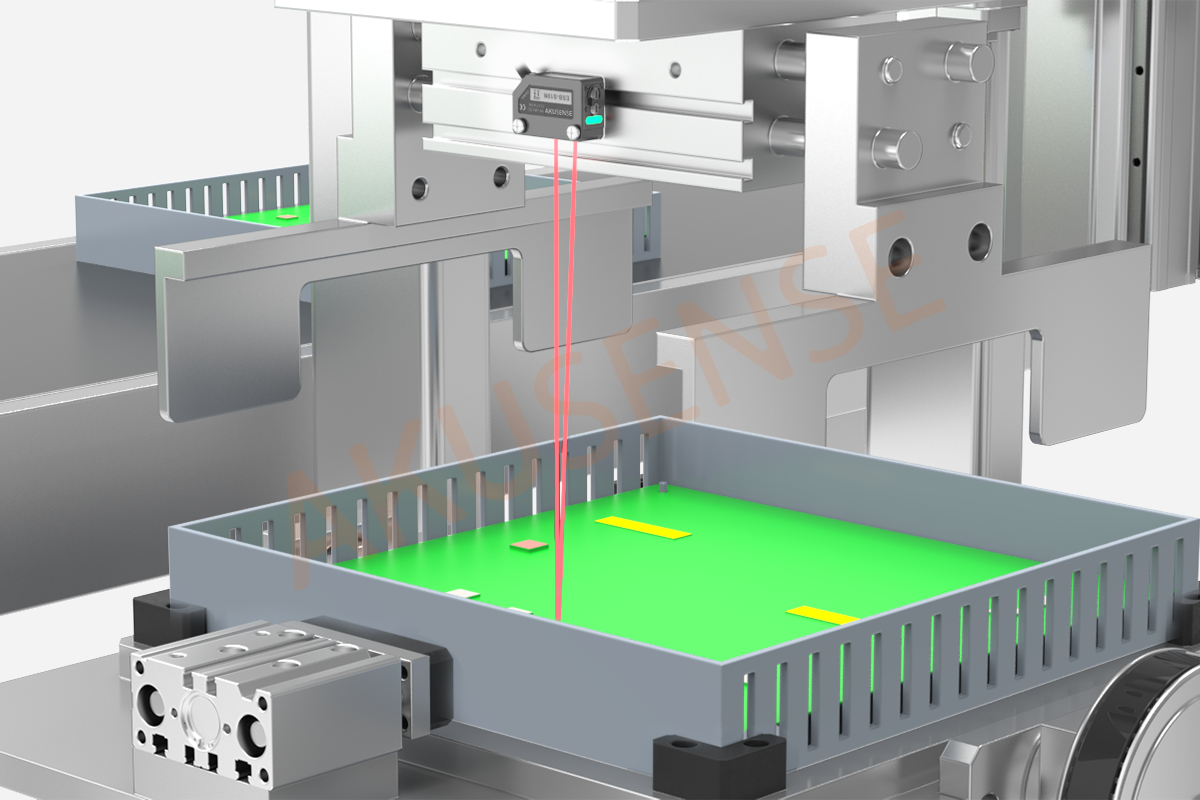

01 Dispensing height measurement

Displacement sensor-MLD21 series

The dispensing machine has extremely high requirements for the positioning of the dispensing height. Laser displacement sensors are generally used to measure the dispensing height. This MLD21-100A has a linear accuracy of up to 0.07mm (wire level), ensuring high-precision measurement requirements. This displacement sensor has 485 communication function, and has two output modes, NPN and PNP, to meet the needs of different signal modes. It also has a one-button teaching function, which is simple and fast to use.

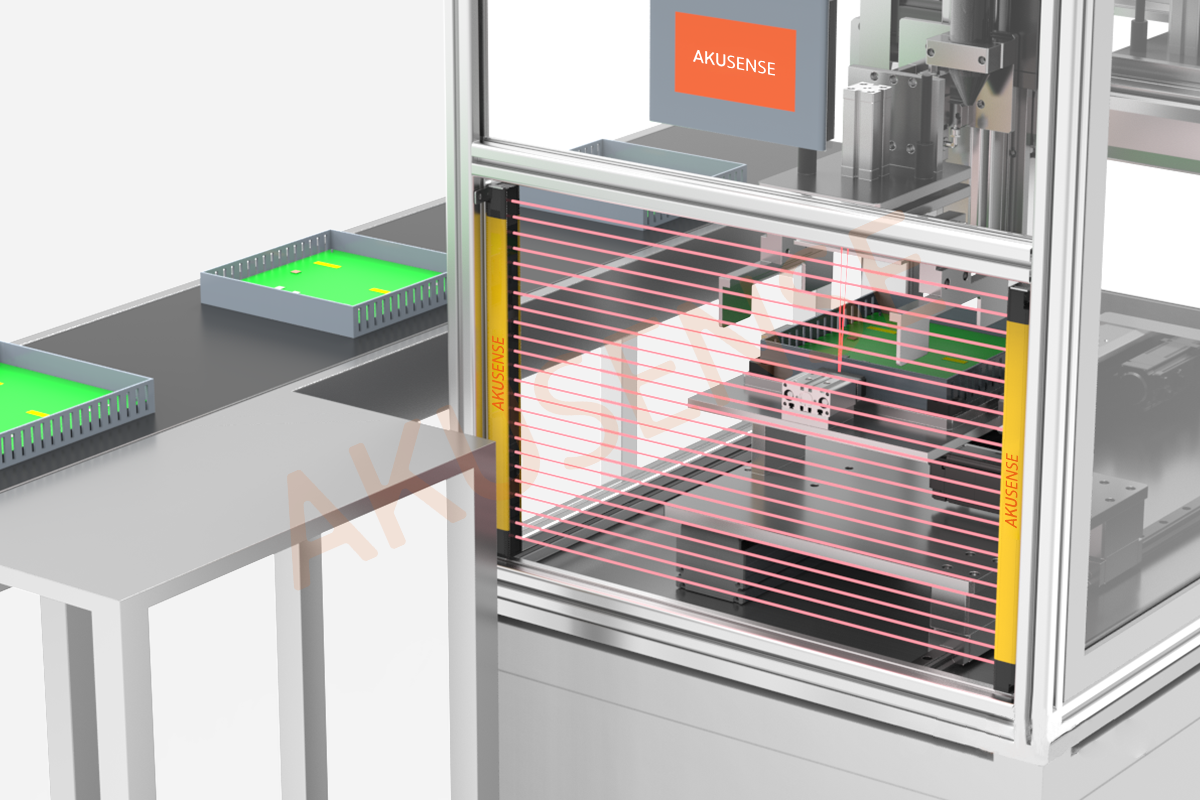

02 Area Protection

Safety light curtain—BKL series

Safety light curtains are installed around the equipment to prevent accidents caused by accidental entry of personnel. Meiji BKL10-T4806NC is selected to customize the protection height for the equipment. The optical axis spacing is 10mm. When an object passes through the protection area, the light curtain will send out an alarm signal. , reminding staff that there is an abnormality in the equipment, which can effectively avoid unnecessary injuries and losses.

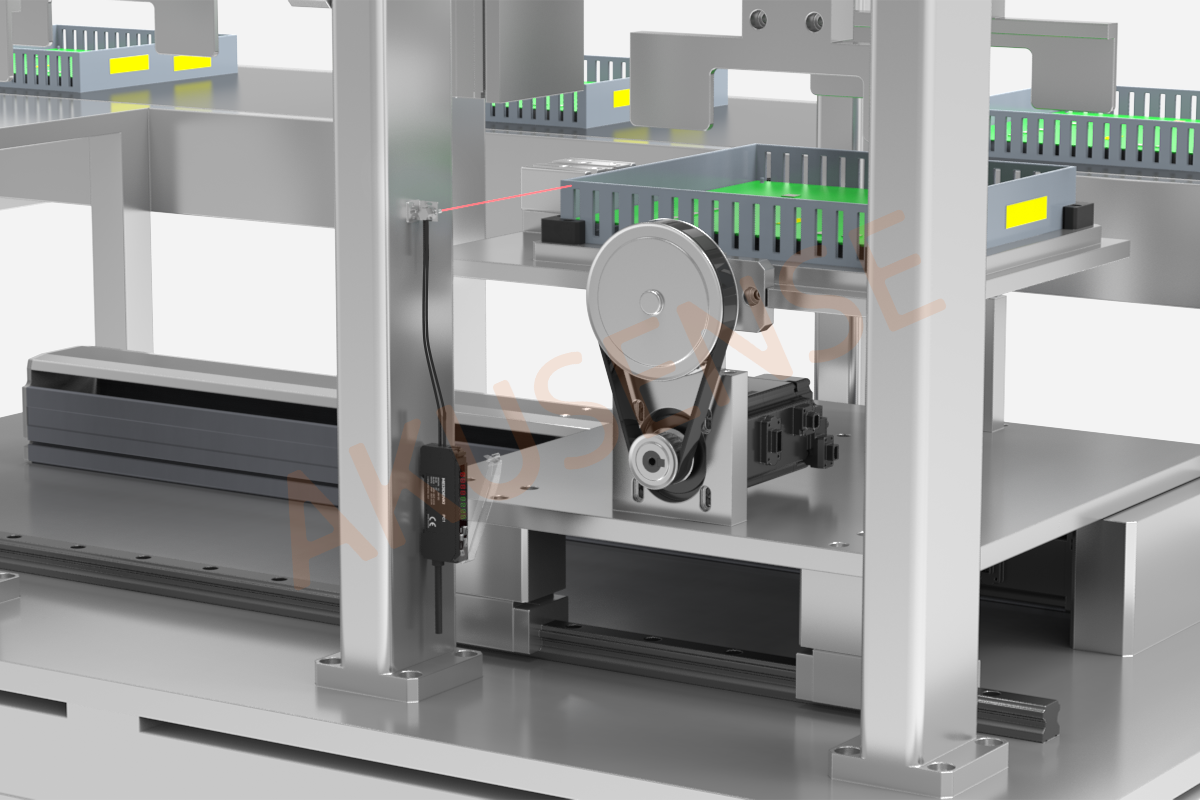

03 Equipment loading

Background suppression photoelectric—ESB-S10N series

Install ESB-S10N at the loading position to detect the presence and arrival of materials. For small PCB boards and motherboards, ordinary large-spot photoelectrics are prone to misjudgment and other phenomena. This photoelectric spot size is only 1.5mm and the detection distance is 100mm. It can detect stably even if the size of the workpiece to be measured changes.

04 Equipment unloading

Fiber Amplifier—PC1 Series

Fiber optic component——PD-C32TZ

When discharging materials, it is necessary to make a quantitative count of good products, so a PC1 amplifier with microsecond-level fast counting function is used, coupled with PD-C32TZ fiber optic components. The design of the coaxial beam ensures that the sensor has stable brightness value feedback, and the detection effect is better. for stability.

+86 18188641602