Work flow of lithium battery winding machine and application of sensors in equipment

Work flow of lithium battery winding machine and application of sensors in equipment

Work flow of lithium battery winding machine and application of sensors in equipmentAccording to the battery production and manufacturing process, lithium battery equipment is divided into front-end equipment, middle-end equipment, back-end equipment, modules and PACK equipment. The equipment value ratio is close to 4:3:2:1. The winding machine is the core of the intermediate equipment for lithium battery cell manufacturing. The winding machine winds the die-cut pole pieces into lithium-ion battery cells. During the winding process, tension control accuracy, deviation correction ability, and winding efficiency have become the keys to the quality of the battery product.

Today I will share with you the workflow of the lithium battery winding machine and the application of sensors in the equipment~

Lithium battery winding machine

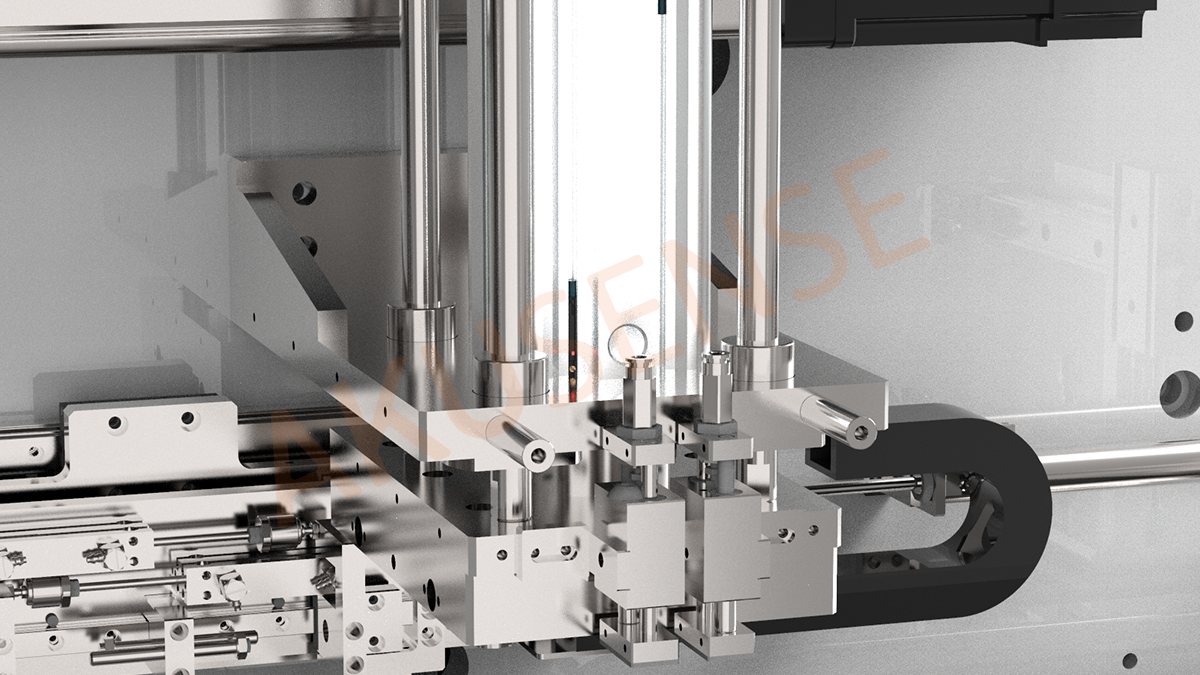

Lithium-ion battery winding machine is used to wind lithium-ion battery cells. The winding machine has positive and negative electrode feeding units, and the part that winds the positive and negative electrodes together is called a winding needle. The important components of the lithium-ion battery winding machine are the frame, winding device, pole piece supply device, auxiliary pressure plate and cutting device, tape supply device, and electrical control part.

Currently, there are semi-automatic winding machines and fully automatic winding machines that are common on the market. Today, Xiao Ming will share with you the fully automatic winding machine, which is suitable for fully automatic winding of power lithium battery cells.

Fully automatic winding machine workflow

Currently, there are semi-automatic winding machines and fully automatic winding machines that are common on the market. Today Xiao Ming will share with you the fully automatic winding machine. It is suitable for fully automatic winding of power lithium battery cells. The main work processes are as follows Four steps:

Features of fully automatic winding machine

1. Adopt AC servo motor drive, tension control unwinding, and the tension is adjustable.

2. There are correction devices for both unwinding and winding

3. The pole piece is automatically corrected, linearly guided and positioned before being fed into the chuck to ensure the winding quality.

4. The loading, winding, termination tape and unloading of pole pieces are all automated to improve battery winding accuracy and efficiency.

Application of sensors in fully automatic winding machines

The use of fully automatic equipment is of great help to the production efficiency and consistency of lithium battery products, and the selection of stable and precise sensor configuration plays a key role in equipment design.

Optical fiber components

In the pole piece and diaphragm, the optical fiber sensor detects whether the pole piece is loaded normally; the corresponding cylindrical type, regional matrix type, flat bracket type and other types of optical fibers can be matched according to the on-site installation conditions and mechanical operation requirements to formulate application plans.

slot sensor

The equipment's motion mechanism is complex, and groove sensors with various appearances such as F/T/R/L/K are commonly used in multiple workstations of the equipment to perform position control such as positioning and limiting the motion mechanism module.

Magnetic sensor

Applied to the upper limit of the cylinder module, the magnetic sensor detects the cylinder position to control the cylinder position;

Square photoelectric sensor

After the positive and negative electrode materials and separators are rolled into small cell units, tape needs to be attached to prevent the cell from loosening or shifting. Here, a square photoelectric detector needs to be used to detect that the cell roll is in place, thereby sending out a signal to proceed to the next step. Gluing operation.

safety light curtain

Carry out safety protection during equipment operation to prevent personal injuries caused by misoperation during equipment operation.

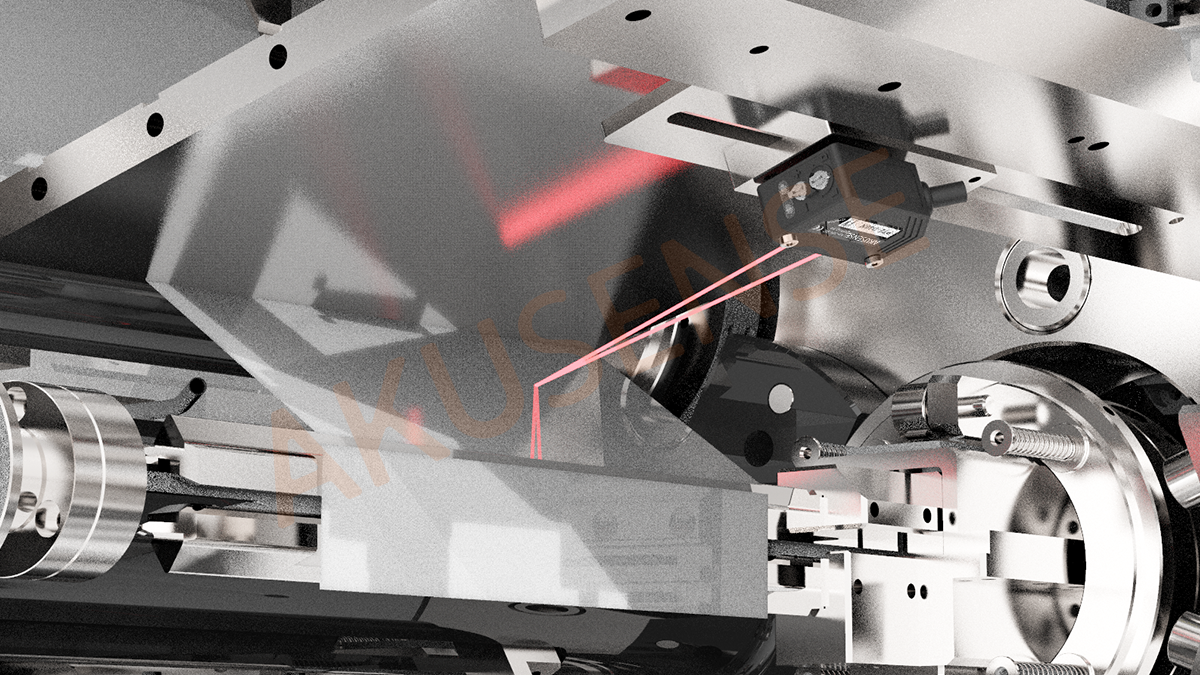

Correction sensor

In order to ensure product consistency, during the battery cell production process, the correction sensor detects the loading process of the pole pieces, and feeds back the detection position results to the correction controller to achieve the effect of timely correction, which affects the stability and accuracy of the sensor. There are extremely high requirements.

Craftsmanship, high quality sensor

As one of the key equipment for the production of lithium batteries, the lithium battery winding machine has a direct impact on the product performance of lithium batteries in terms of winding speed, accuracy, stability and automation. It also poses more and more challenges to winding machine manufacturing companies. The more stringent the requirements, Meiji Sensors creates high-quality sensors with ingenuity, providing support for lithium battery winding machine manufacturing companies to become industry leaders.

+86 18188641602