In the new energy era, these sensors help laser welding equipment seize the tens of billions market

In the new energy era, these sensors help laser welding equipment seize the tens of billions market

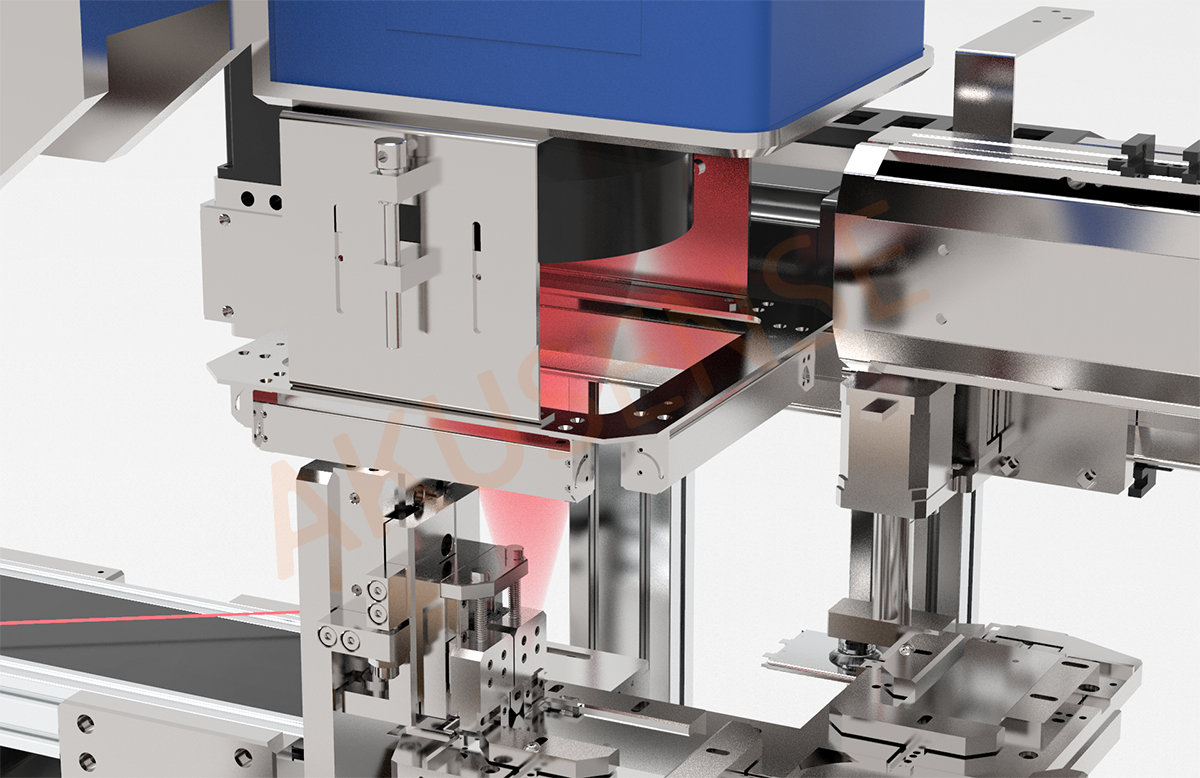

Driven by the dual-carbon policy, the energy storage field may usher in a golden period. A new round of power battery investment and production expansion will drive demand for equipment, and higher and higher requirements will be placed on the accuracy, sLithium battery laser welding machine

Laser welding process is an important process in lithium battery manufacturing. It has the advantages of high precision, fast speed and high level of automation. It directly affects the cost, quality, safety and consistency of the battery. Before the emergence of laser technology, the lithium battery industry usually used traditional machinery for processing and cutting. During use, the die-cutting knife will inevitably wear and tear, causing dust to fall off and burrs to occur, which may cause the battery to overheat, short-circuit, and explode. and other dangerous problems; and the hardware die-cutting process has limitations such as fast mold loss, long mold change time, poor flexibility, and low production efficiency, and it is increasingly unable to meet the development requirements of lithium battery manufacturing.

Laser welding machine VS ordinary welding machine

Compared with traditional welding processes, laser welding has high energy density, small welding deformation and small heat-affected zone, which can effectively improve the accuracy of parts. The welds are smooth, impurity-free, uniform and dense, and do not require additional grinding work. Secondly, laser welding can achieve precise Control, small focused light spot, high-precision positioning, easy to realize automation with robotic arms, improve welding efficiency, reduce working hours, and reduce costs; in addition, when laser welding thin plates or thin-diameter wires, they are not as susceptible to meltback as arc welding trouble.

Laser welding machine workflow

Application of sensors in laser welding machines

Laser welding equipment is widely used in lithium battery manufacturing. It runs through almost every link of production. It can weld and seal battery structural parts economically and quickly. It is used in battery explosion-proof valves, pole welding, adapter plate welding, and shell welding. Body sealing, battery tabs, power battery modules and PACK welding, etc.

industrial camera

Using cameras to position and track lithium batteries and detect product defects has the following advantages:

1. With the IA box (small size), it can replace the original industrial computer and reduce the space used by the equipment; 2. Instead of the traditional PC for calculation and image processing, the smart camera (box) serves as the hardware platform for the AI algorithm; 3. Use deep learning Automatically extract image features instead of artificially designed features, and have stronger generalization capabilities.

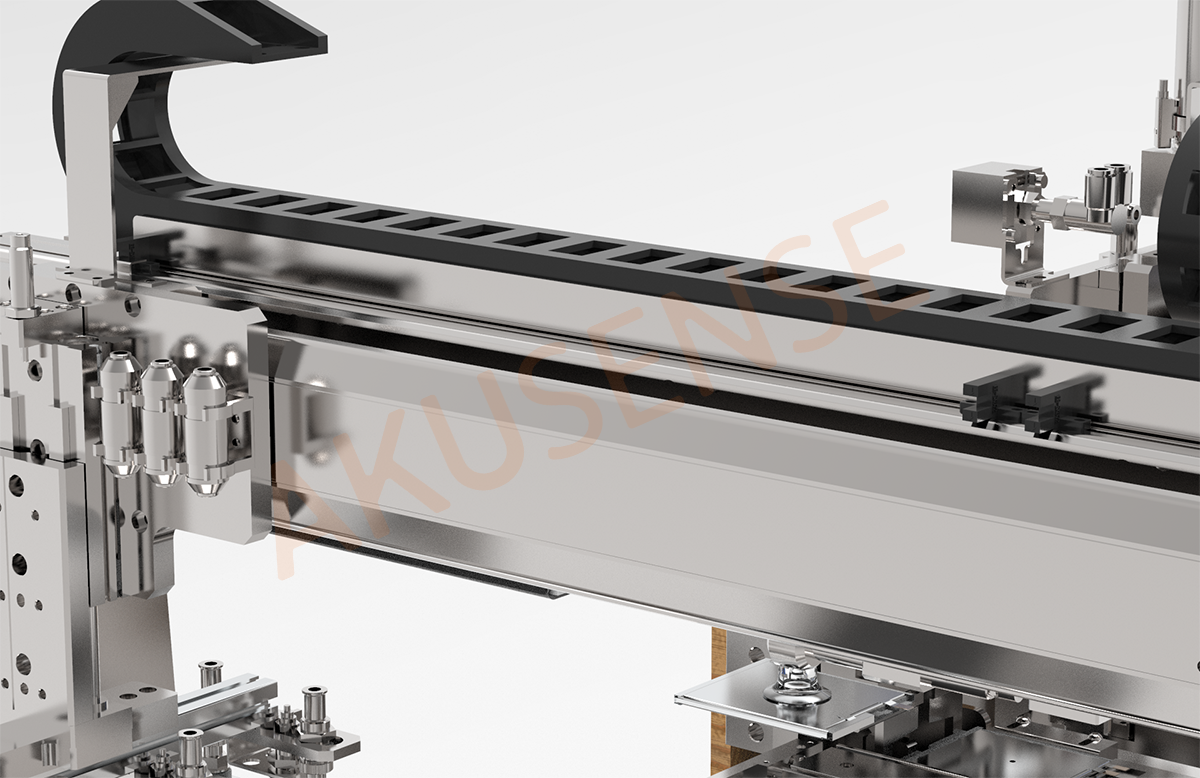

slot sensor

The positioning limit applied to the motion mechanism module has the following advantages:

1. There are 12 shapes available, including outlet type and plug-in F.T.R.L.K.T., which can be used in a variety of scenarios;

2. Normally open and normally closed output can be switched;

3. The groove depth is 8.5mm, which can prevent the measured object from hitting the bottom of the groove to the greatest extent.

Magnetic sensor

Applied to the upper limit of the cylinder module, the magnetic sensor detects the position of the cylinder to control the lifting and falling of the cylinder. It has the following two advantages:

1. Positioning accuracy and reliable performance;

2. The maximum switching frequency can reach 1000Hz.

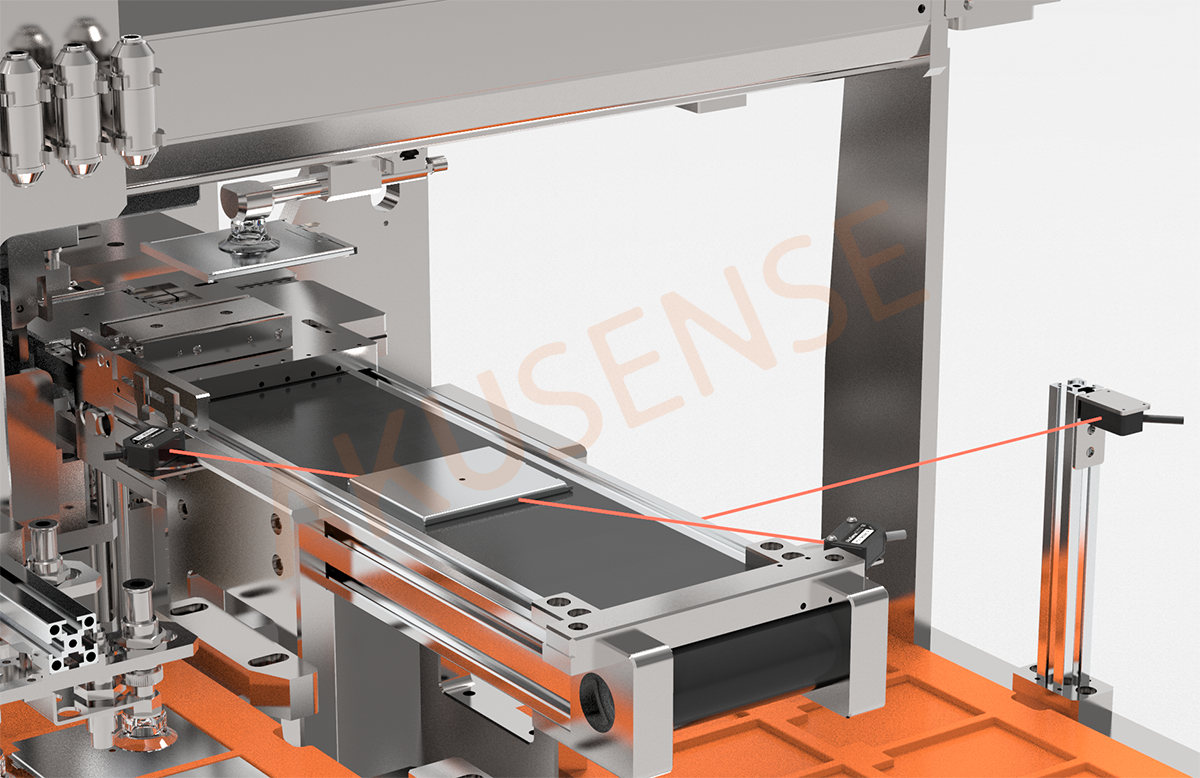

Through-beam photoelectric sensor

It is used to detect the presence of loaded lithium batteries. Since the customer's conveyor belt and mobile platform will jitter, the use of through-beam photoelectricity can ensure the stability of the detection and has the following advantages:

1. Through-beam photoelectricity is not affected by the color of the object being measured;

2. There are few restrictions on detection objects. Since the photoelectric sensor is based on the detection principle of light shading and reflection caused by the detection object, it can detect almost all objects such as glass, plastic, wood, liquid, etc.;

3. Short response time and high resolution.

safety light curtain

Implementing safety protection during equipment operation to prevent dangers caused by personnel accidentally entering during equipment operation has the following advantages:

1. It can provide detection of various sizes of fingers, palms, arms, etc., and can detect opaque objects with a minimum size of 3.75mm or more;

2. Various appearance sizes, protection heights, and detection methods are optional;

3. Can be quickly customized according to various non-standard needs of customers.

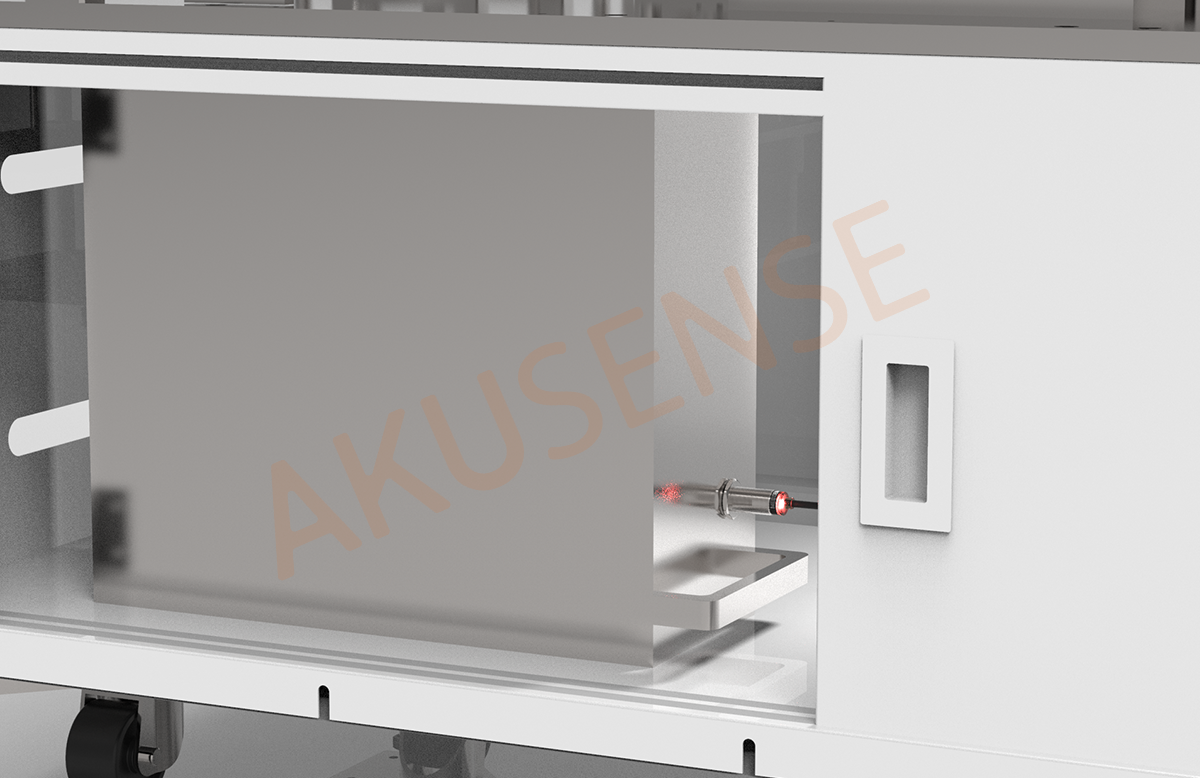

Temperature Sensor

Detecting the temperature of the cooling water chiller has the following advantages:

1. Suitable for small pipe diameters and confined spaces;

2. Fast response time;

3. Different probe lengths and diameters are available.

Laser processing technology is one of the innovations in traditional processing technology in the lithium battery industry, and plays a prominent role in power battery production. Meiji Sensors is manufactured with ingenuity and high-quality sensors to provide support for lithium battery intelligent manufacturing equipment companies to become industry leaders.

+86 18188641602