These sensors are essential to speed up the intelligent manufacturing upgrade of lithium batteries

These sensors are essential to speed up the intelligent manufacturing upgrade of lithium batteries

These sensors are essential to speed up the intelligent manufacturing upgrade of lithium batteriesThe country has always advocated energy conservation and environmental protection, cultivating emerging industries, and gaining new competitive advantages in the future. New energy has become the engine of technological development. As the protagonist of environmental protection and energy conservation, lithium batteries have always attracted market attention and have entered an era of high-quality and diversified competition.

Under the current wave of smart manufacturing and Industry 4.0, how lithium battery manufacturers focus on quality and cost, quickly improve production capacity and quality through a series of automation and digital technologies, and at the same time reduce costs and increase efficiency, is a key issue for future competition. Important investment.

To this end, AKUSENSE provides innovative solutions based on sensing automation technology and has become an important intelligent manufacturing transformation partner for enterprises in the lithium battery industry.

In this issue, we will share with you some application cases of AKUSENSE in lithium battery production.

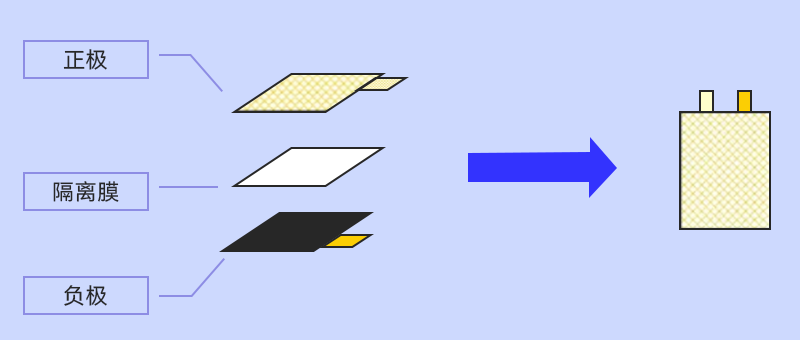

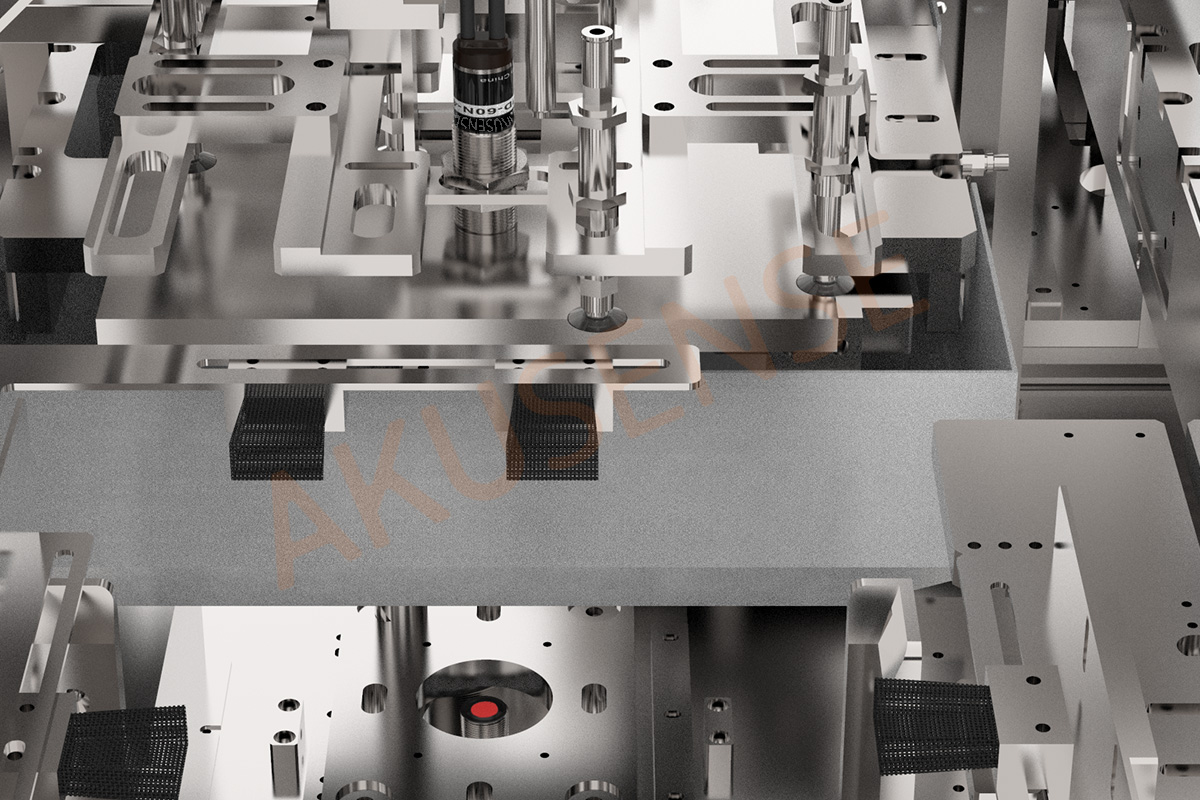

The lithium battery lamination machine is one of the key equipments for battery production in the lithium battery industry. It is a mid-stage cell synthesis process in lithium battery production. Its main function is to assemble the positive and negative electrodes of lithium battery cells and the isolation film into Z-shaped laminations. Stack them to form small battery cells, and then stack the small battery cells in parallel to form a large battery cell.

Application of sensors in stacking machines

Lamination technology can effectively improve the energy density, endurance and safety performance of lithium batteries. It is not only the first choice for mobile devices, but also has high hopes for new energy vehicles. However, there are many battery models using lamination technology and the manufacturing process requirements are high, resulting in The degree of automation is low and product consistency is poor, seriously affecting production capacity. In order to solve this problem, Meiji Sensors has developed a complete set of sensor application solutions to help lamination machine manufacturing companies improve the efficiency of core equipment.

1. Square proximity sensor

After the material box comes from the transmission line and reaches the loading station, the motor moves the upper material box jig to the predetermined position. During this process, the proximity switch controls the origin and limit position of the upper lifting mechanism.

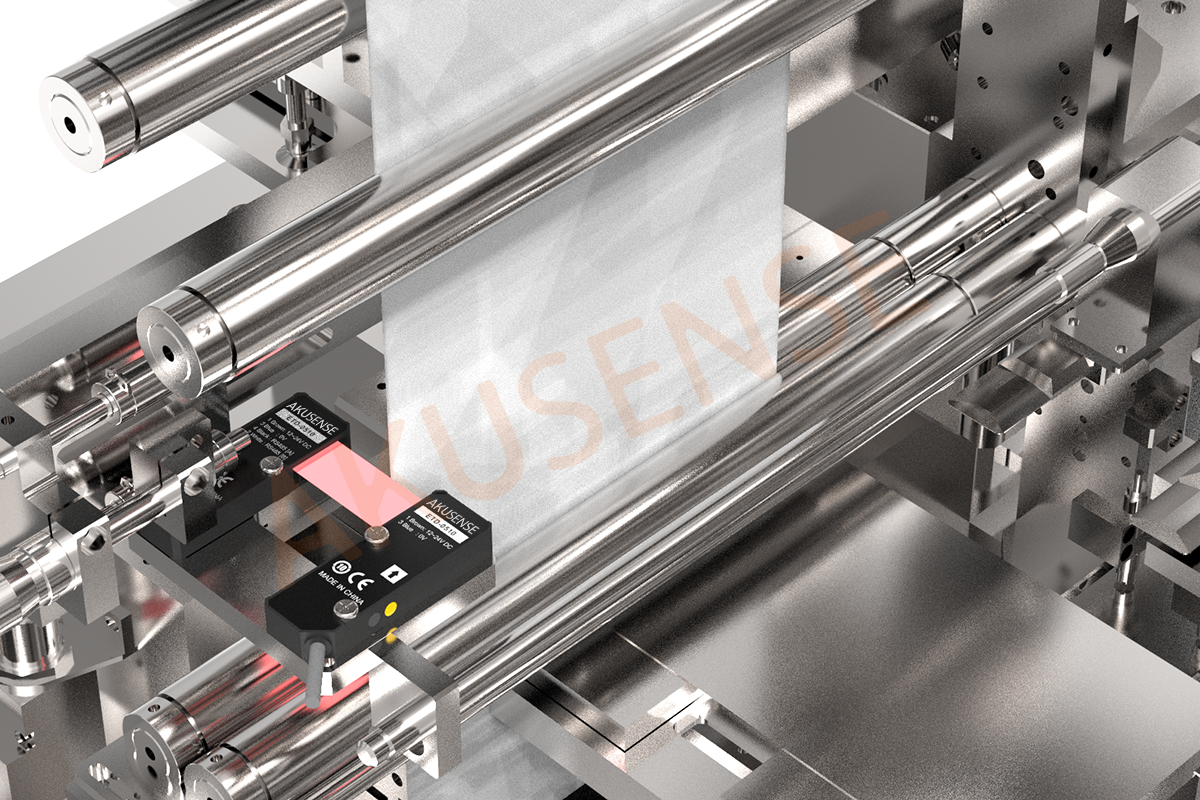

2. Ultra-thin photoelectric ESL series

Detect whether there are pole pieces in the pole piece material box, and provide timely loading instructions.

3. Diffuse reflection photoelectric PTE series

Detect the position of the battery pole piece, and the next step will be triggered when the pole piece is in place.

4. Correction sensor

The pole pieces are pre-positioned to detect the edge position of the diaphragm during the diaphragm transfer process, and feed it back to the correction system to control the positional deflection of the diaphragm during the transfer process.

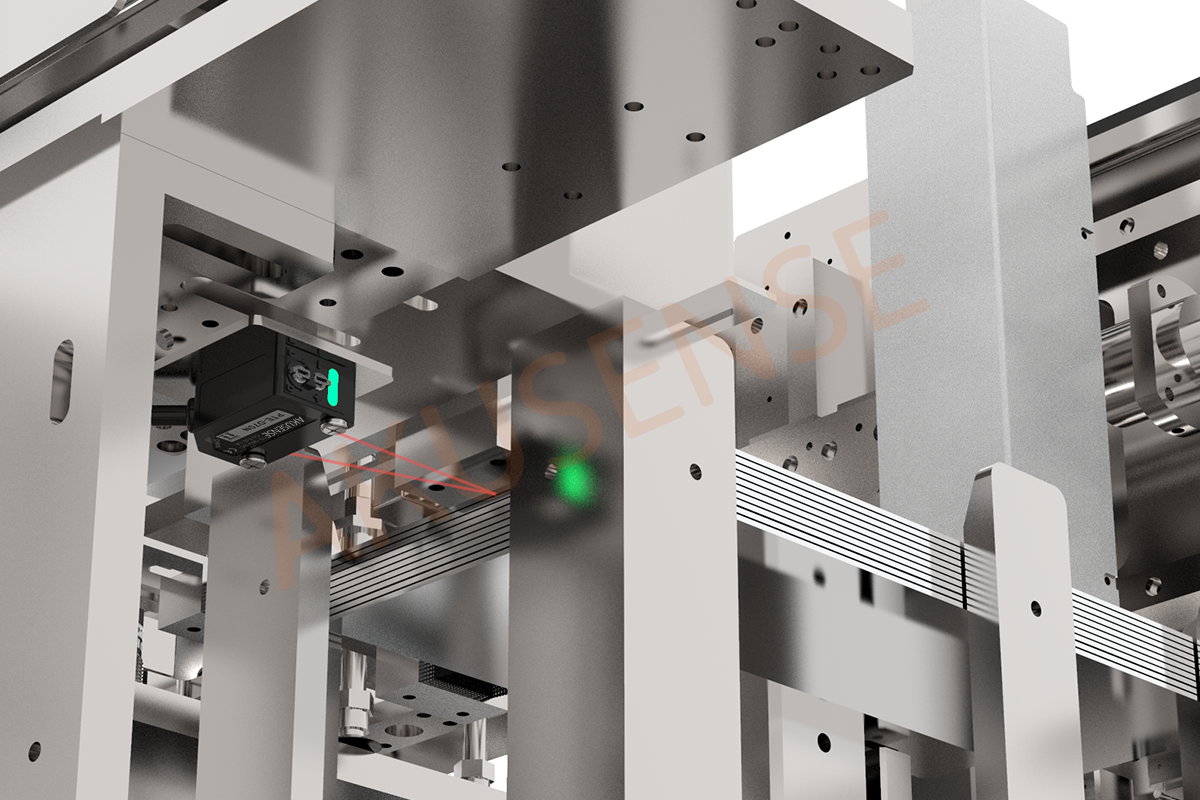

5. Groove sensor

It is widely used at multiple points inside the machine to control the origin and limit position of the mechanism module and the position of the roller axis.

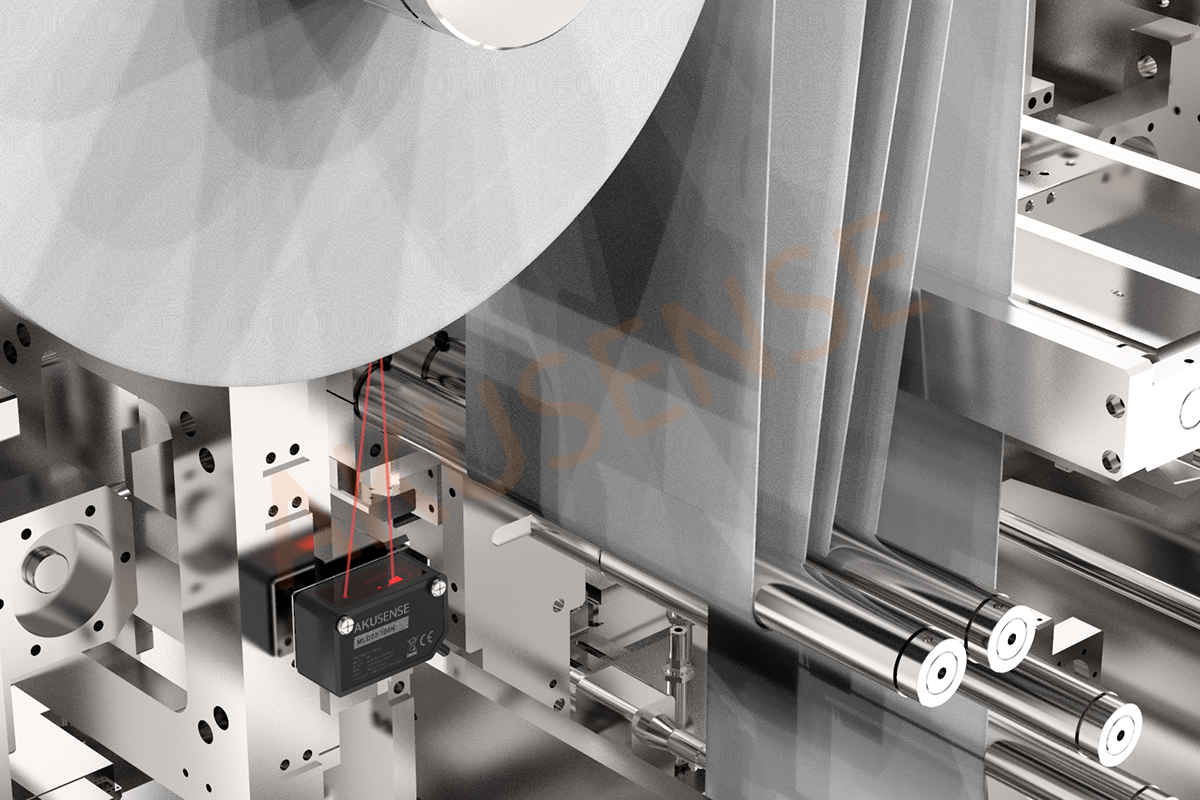

6. Laser displacement MLD23 series

The remaining diaphragm material on the diaphragm transmission module is detected and the feeding instructions are fed back in time.

7. Ultrasonic single and double MUD series

On the pole piece position correction module, the single and double status of the positive and negative pole pieces is detected.

+86 18188641602