The intelligent sensing solution of lithium battery lamination machine is upgraded again

The intelligent sensing solution of lithium battery lamination machine is upgraded again

As one of the key equipment for the production of lithium-ion batteries, the lithium battery lamination machine can effectively improve the energy density, endurance and safety performance of lithium batteries.As one of the key equipment for the production of lithium-ion batteries, the lithium battery lamination machine can effectively improve the energy density, endurance and safety performance of lithium batteries. It is not only the first choice for mobile devices, but also has high hopes for new energy vehicles.

Its lamination speed, accuracy, stability and degree of automation all have a direct impact on the product performance of lithium batteries, and also put forward more stringent requirements for lamination machine manufacturing companies. Under the current wave of smart manufacturing and Industry 4.0, how lithium battery manufacturers focus on quality and cost, quickly improve production capacity and quality through a series of automation and digital technologies, and at the same time reduce costs and increase efficiency, is a key issue for future competition. Important investment.

AKUSENSE is built with ingenuity and high-quality sensors to provide support for lithium battery stacking machine manufacturing companies to become industry leaders and constantly upgrade solutions. We always believe that in order to remain competitive, breakthroughs in new technologies and new products are important. The most important thing; in this issue, Xiao Ming will share Meiji Sensing’s newly upgraded lithium battery stacking machine solution~

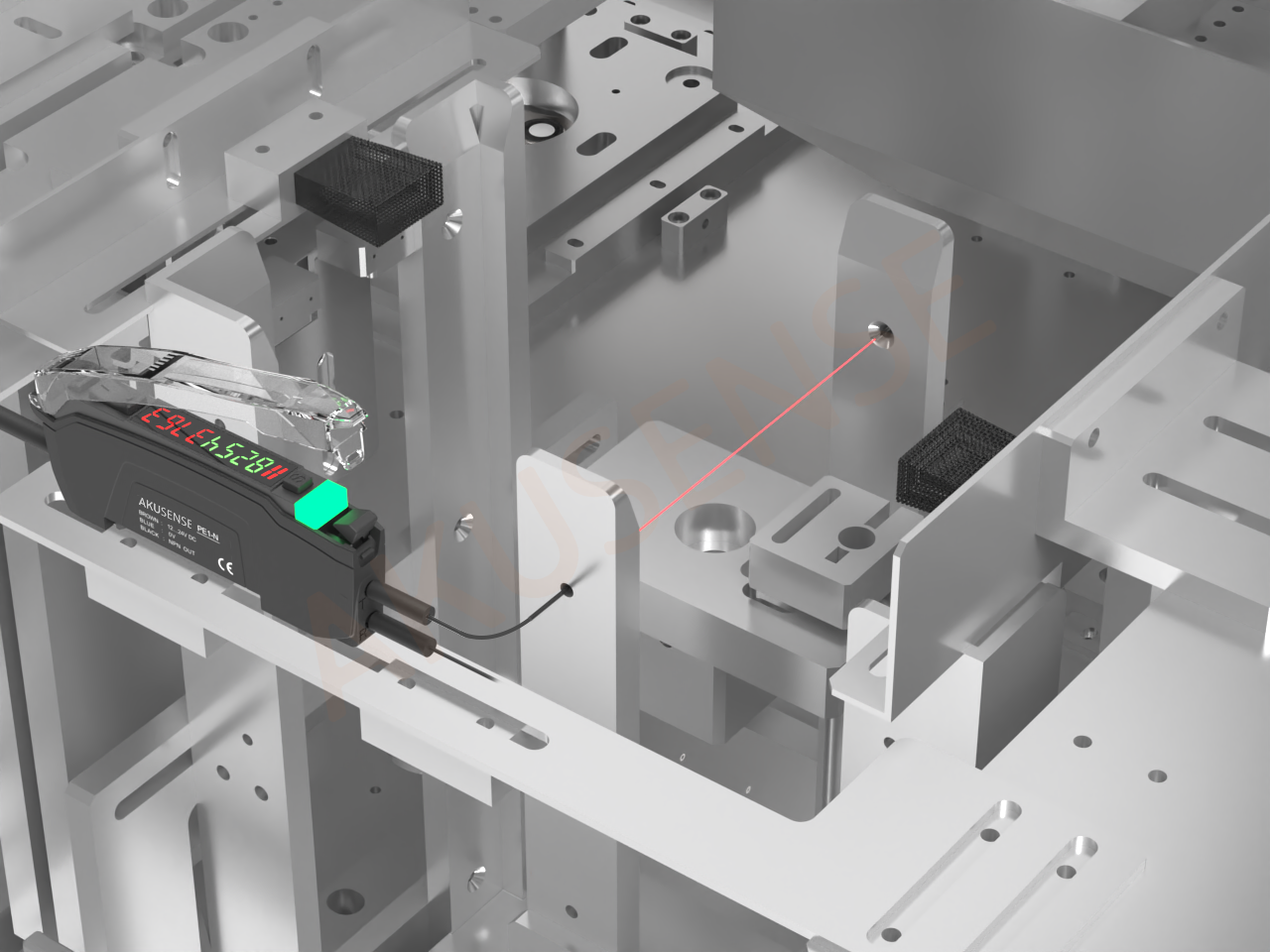

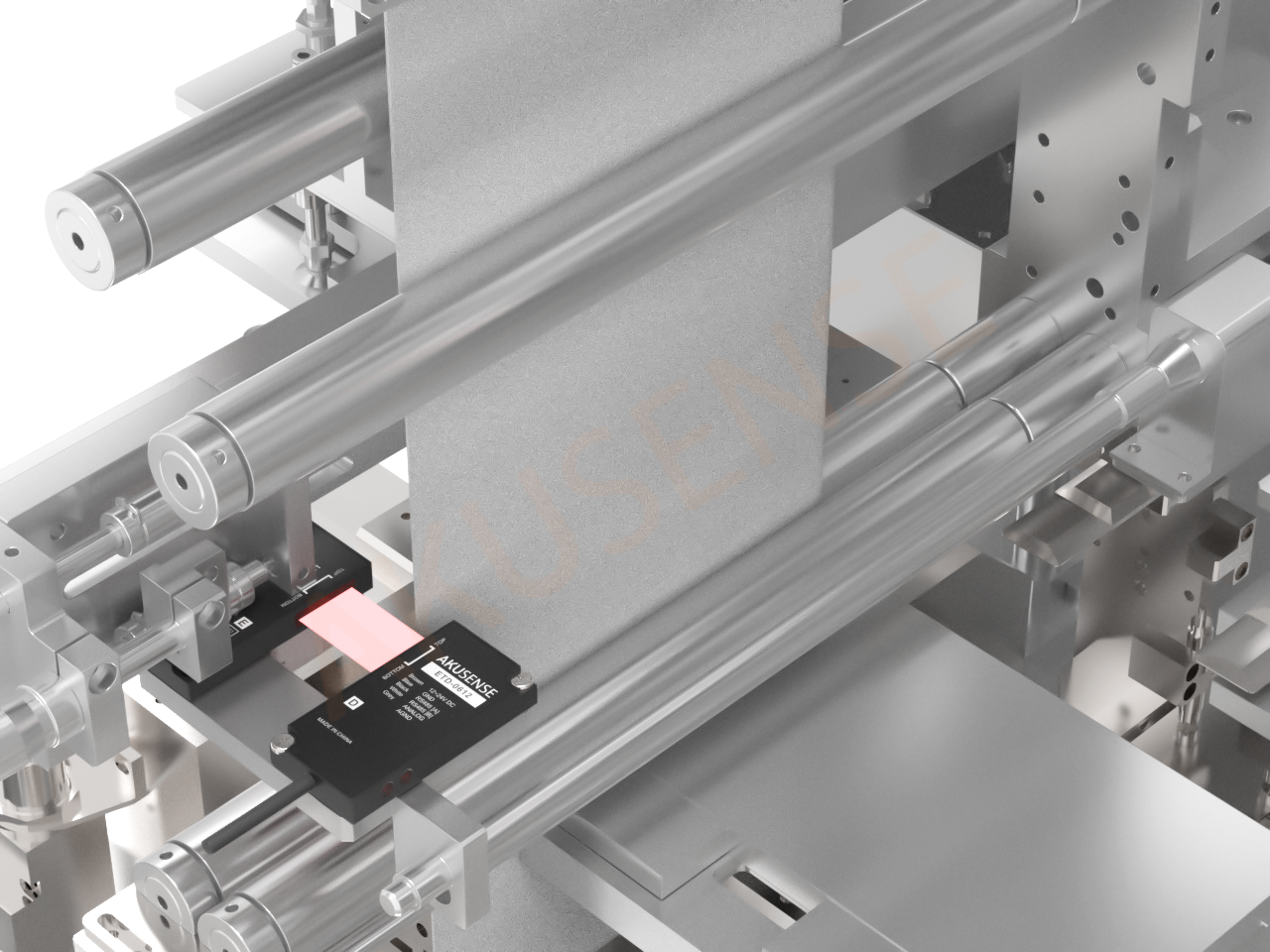

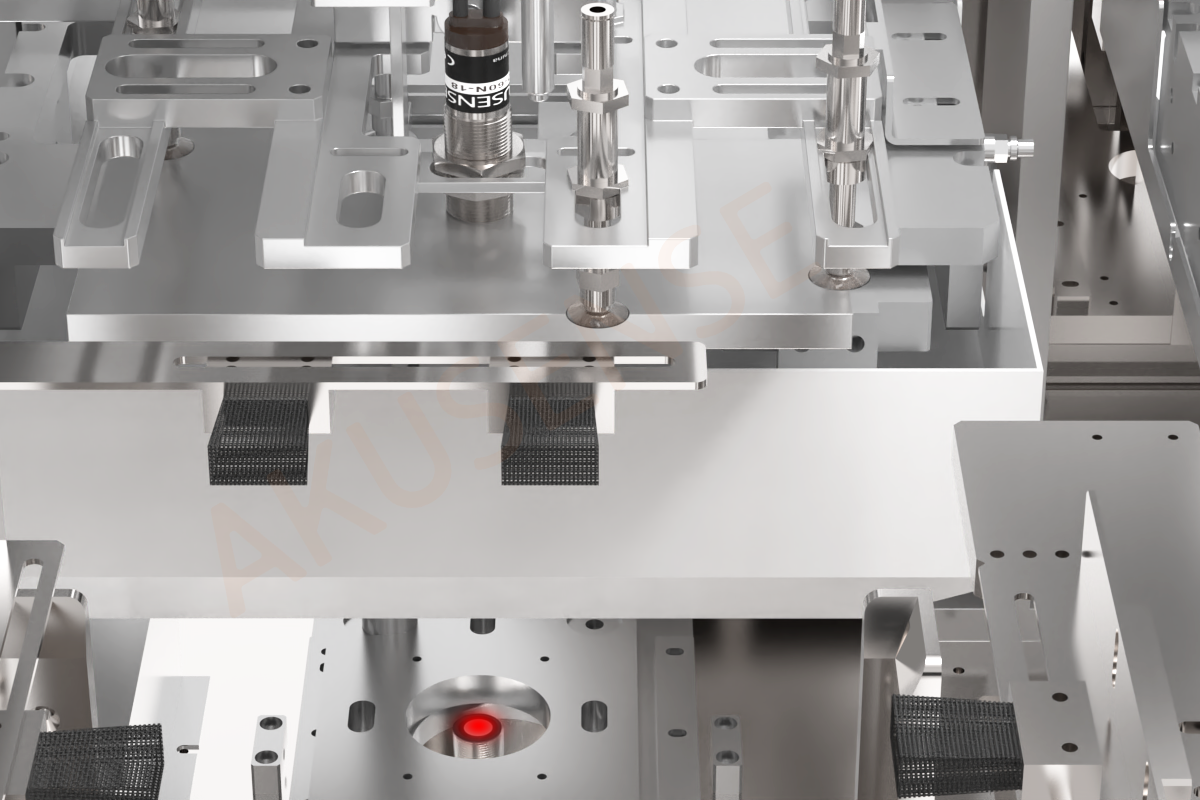

01 Check whether the positive and negative electrode plates are in place

Fiber optic sensor PE1+PT-R58V

Application scenarios:

The sensor detects the position of the battery pole piece. When the induction pole piece is in place, the next step is triggered. The detection distance is between a few millimeters and tens of millimeters.

solution:

1. Using fiber optic sensors. The amplifier PE1 and PT-R58V components are small, easy to install and have high flexibility.

2. The detection distance is about 130mm, and the effective signal can be set according to the light value returned by the material.

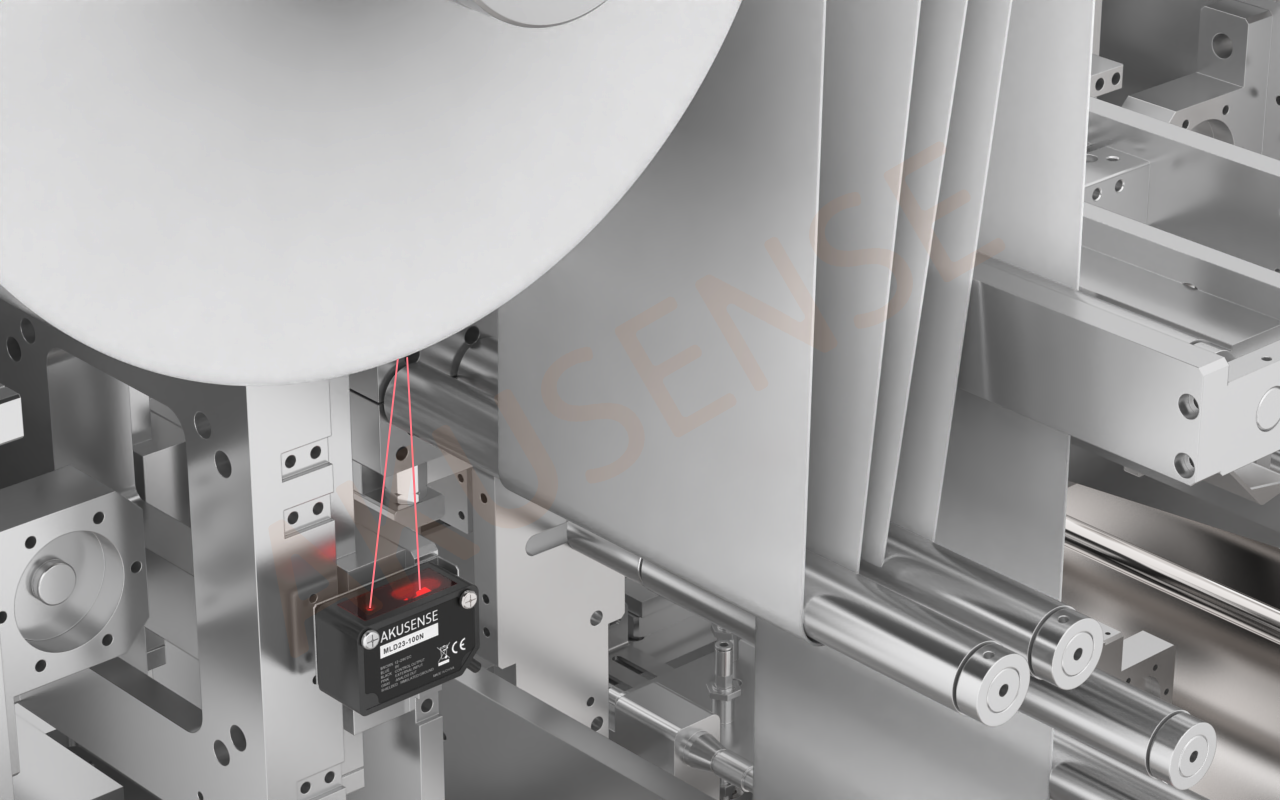

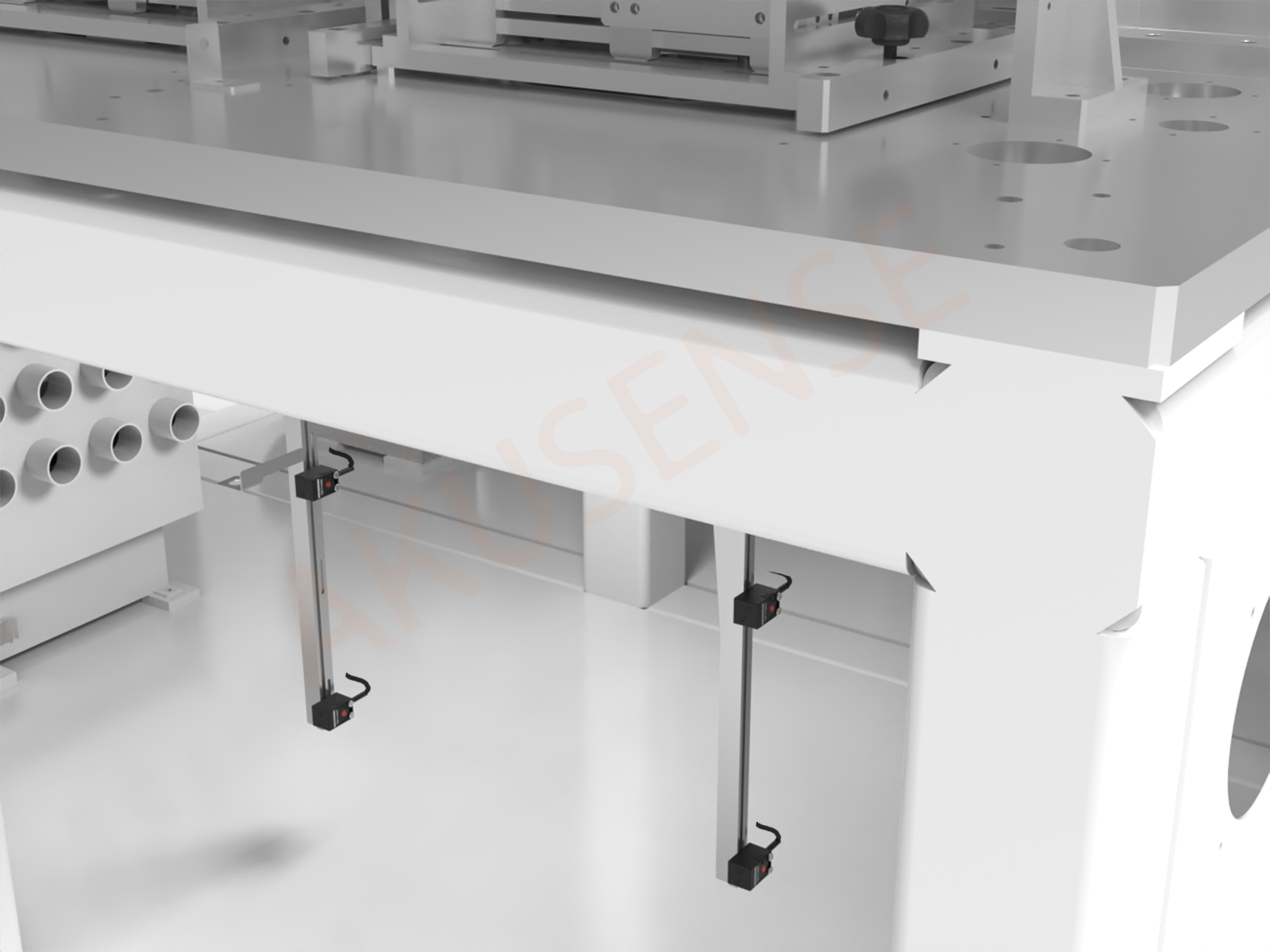

02 Diaphragm loading and remaining material monitoring

MLD23 series laser displacement sensor

Application scenarios:

It is necessary to detect the remaining material of the battery separator on the laminating machine equipment. When the separator material roll is about to be exhausted, the sensor feedback signal will respond to the equipment and remind the operator to replace the material roll in time.

solution:

1. Akusense laser displacement sensor MLD23 series is used to achieve high-precision distance detection through laser triangulation.

2. The detection distance of this product can reach up to 280mm, which can meet the diameter measurement requirements of diaphragm rolls of different specifications.

3. It has a voltage output of 0-5V and a current output of 4-20mA, which can interact with the PLC on the equipment to realize real-time monitoring of the diaphragm roll diameter.

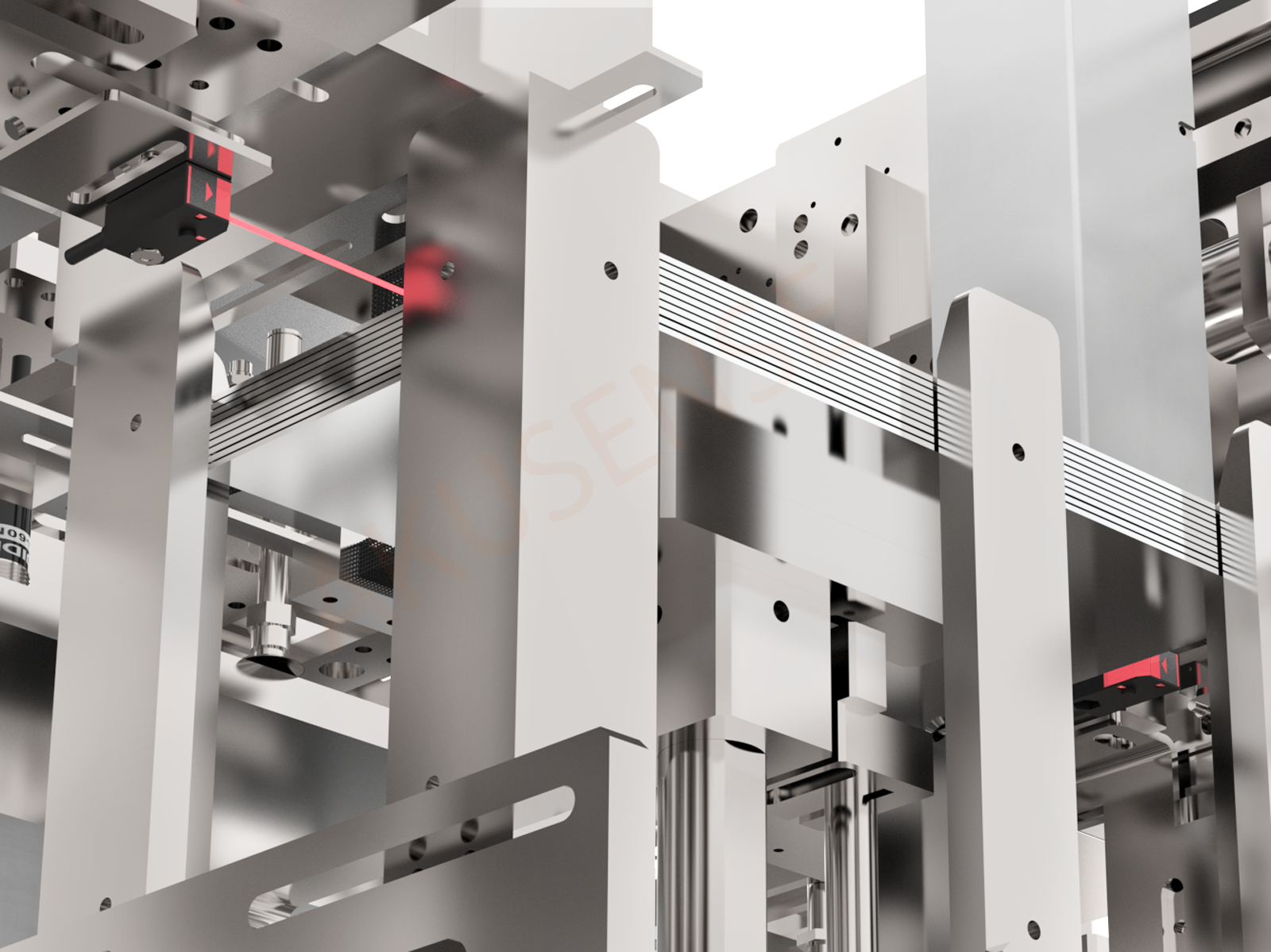

03 Positioning of battery pole pieces

PTJ series photoelectric sensor

Application scenarios:

The material is detected in place at the positive and negative material loading stations on the equipment. When the positive and negative electrode plates reach the set position, the photoelectric switch output signal is triggered to drive the equipment manipulator to pick up the material.

solution:

1. Small photoelectric through-beam switches PTJ series are installed on both sides of the workstation. They are only the size of a tail finger and can be installed in the compact space of the loading station.

2. The product uses invisible infrared light source, which will not have any impact on the photoelectric switches at nearby work stations and equipment operators.

3. L.on (light entry action) /D.on (light blocking action) can be switched and the sensitivity can be adjusted; dual LED indicator light design can clearly identify the action situation

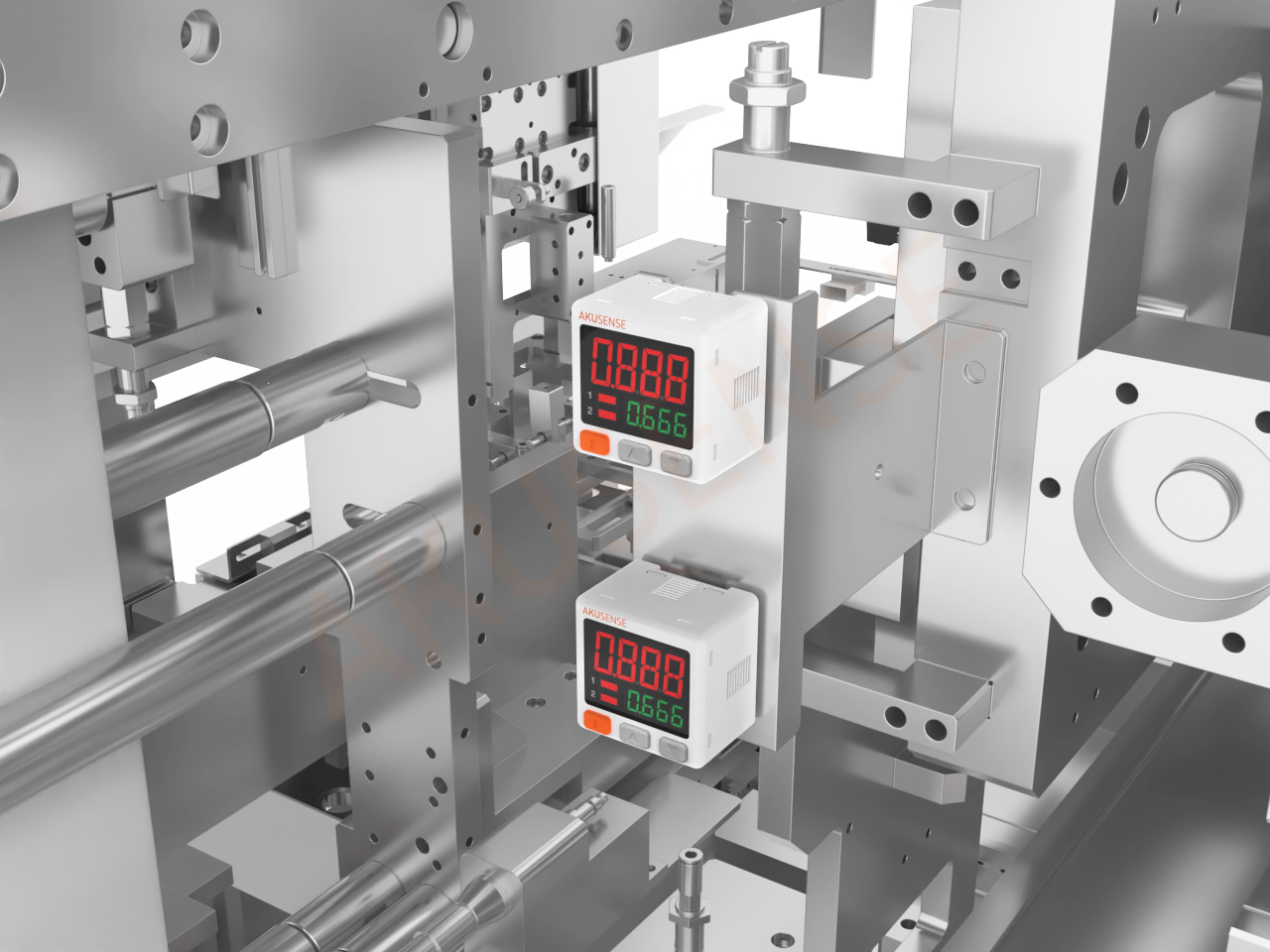

04 Detect lamination pressure

MQ-10 pressure sensor

Application scenarios:

Detect the pressure during lamination to ensure that the pressure during the lamination production process meets the set requirements

solution:

1. Use the Akusense digital display pressure sensor MQ-10 series to provide high-precision air pressure measurement results, with values accurate to several decimal places.

2. Simple structure and long service life. Easy to use, no complicated operations required

05 Pole piece transmission positioning correction

Precision correction sensor ETD-0612

Application scenarios:

The edge position of the diaphragm is detected during the diaphragm transfer process and fed back to the deviation correction system to control the positional deflection during the diaphragm transfer process.

solution:

1. ETD-0612 series deviation correction sensor is selected. Through the laser beam principle, the steady-state laser image data processing mode produces clearer images, while reducing interference items, achieving higher resolution and better detection results.

2. Accuracy 1um

3. 1ms ultra-high-speed response time, which can meet the needs of high-speed detection

06 Box limit control

TQF18-05NO proximity sensor

Application scenarios:

After the material box comes from the transmission line and reaches the loading station, the motor moves the upper material box jig to the predetermined position. During this process, the proximity switch controls the origin and limit position of the upper lifting mechanism.

solution:

1. Use Akusense square proximity sensor TQF18-05NO, with high repeatability <1.0% (Sr)

2. Switching frequency 1KHz

3. IP67 protection level, effectively enhancing product performance

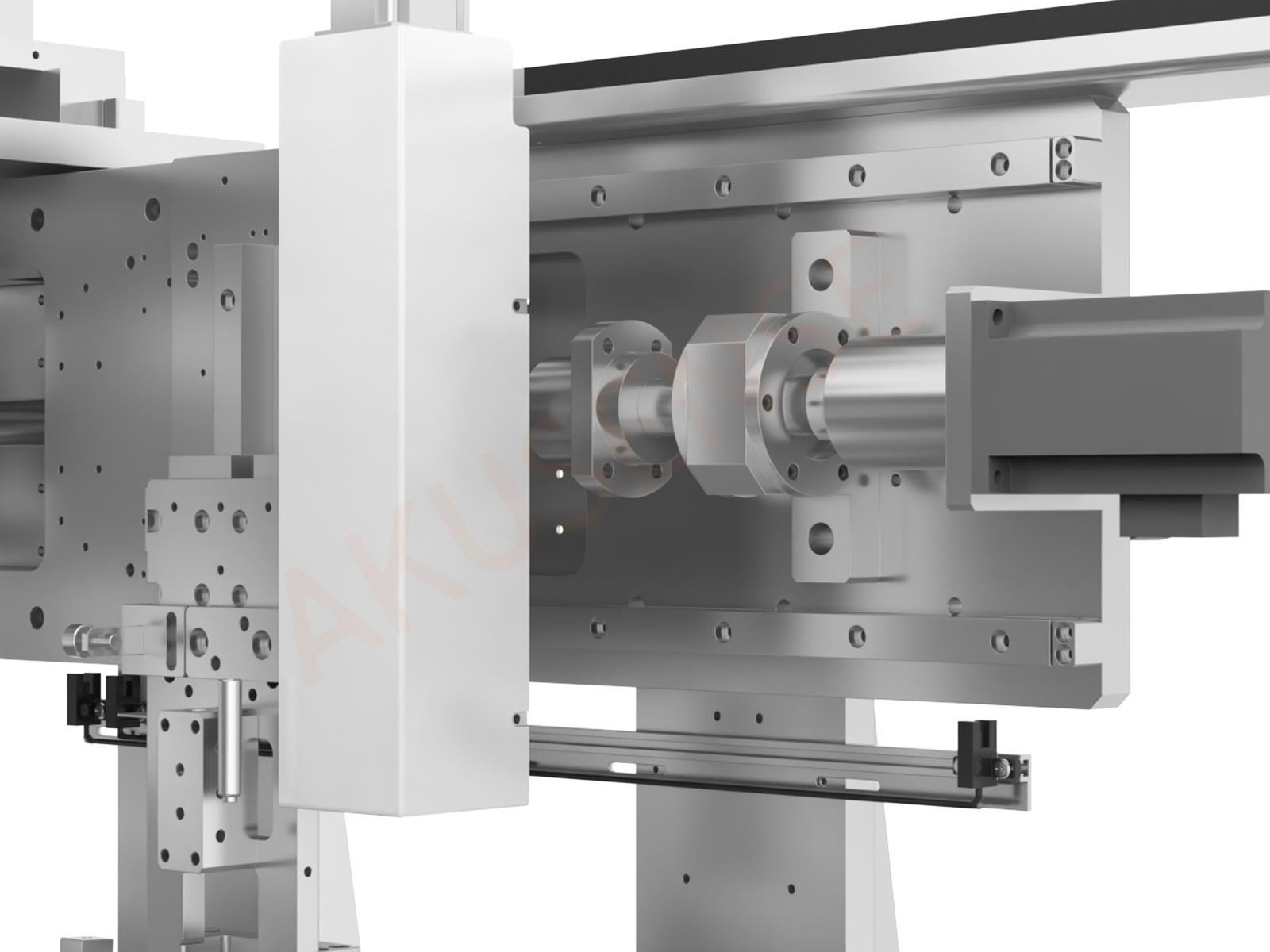

07 Mechanism limit

SF-302N-W series slot sensor

Application scenarios:

It needs to be widely used at multiple points inside the machine to control the origin and limit position of the mechanism module and the position of the roller shaft.

solution:

1. Choose trough sensor SF-302N-W series, non-contact sensing, various types and shapes, you can choose freely according to the actual situation

2. Response time is less than 0.3ms

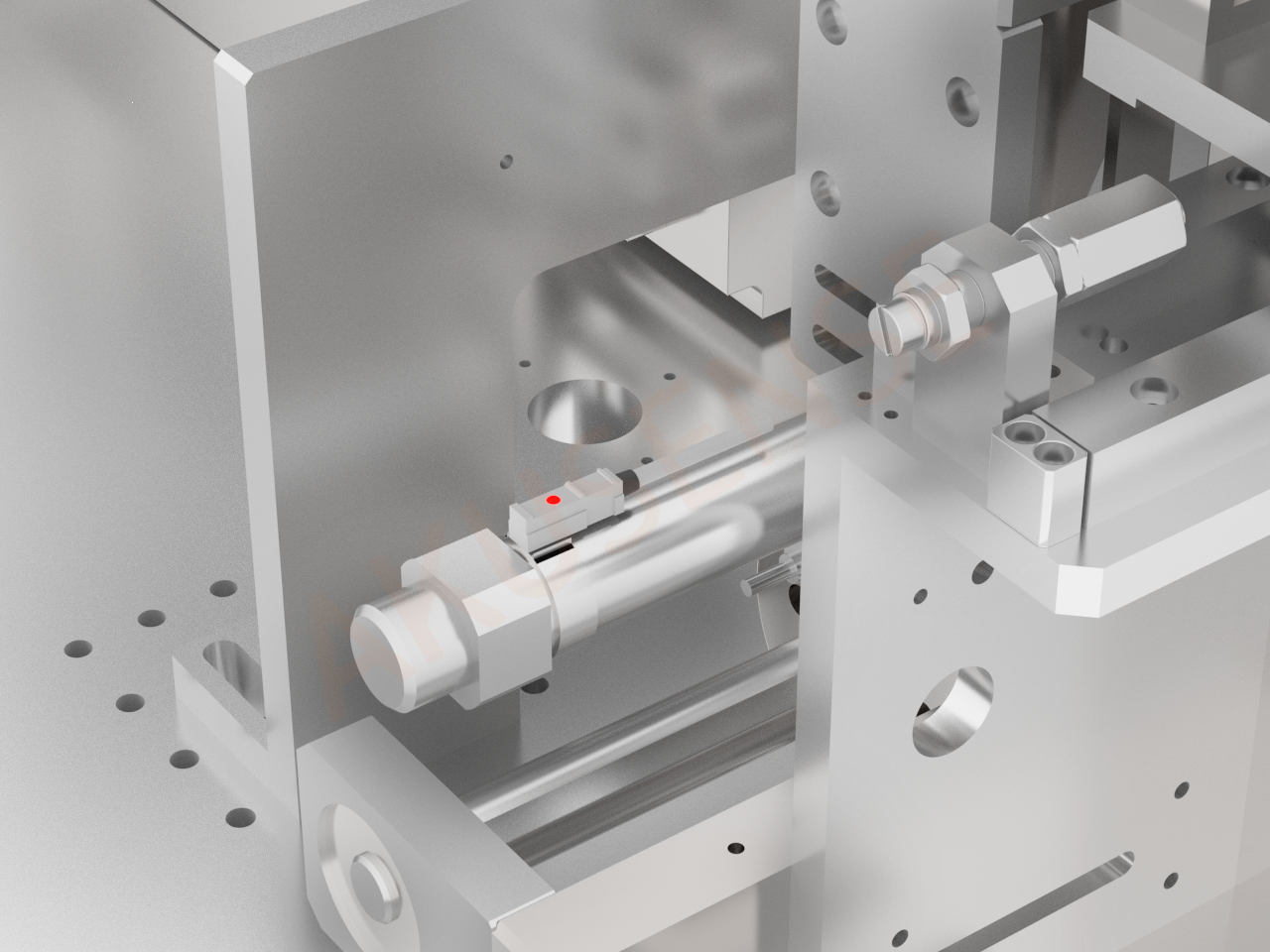

08 Detect cylinder expansion and contraction status

MR-C12-N series magnetic sensor

Application scenarios:

Detect the expansion and contraction status of the cylinder to determine whether the cylinder is working normally and ensure the stability of the equipment during operation.

Solution:

1. The Akusense magnetic sensor MR-C12-N series can detect based on the magnetic principle. It is not easy to receive external interference and damage, with high reliability.

2. Able to achieve high-precision position and status detection to meet high-precision industrial control needs

09 Detection of single and double pole pieces

MUD series ultrasonic sensor

Application scenarios:

On the stacking machine equipment, before the positive and negative electrode plates are transported to the stacking station for lamination, the positive and negative electrode plates of the battery need to be inspected for heavy materials to avoid overlapping of the electrode plates, which may cause safety hazards in the subsequently produced cells.

solution:

1. Akusense MUD series single and double sheet sensors adopt the ultrasonic principle and realize material stacking and lack of material detection by detecting the sound wave signal strength feedback at the receiving end.

2. The product has multiple detection modes and self-learning functions, which can teach according to different specifications of materials.

3. It can adapt to the detection requirements of single and double sheets of materials of various materials and thicknesses, and the detection effect is stable.

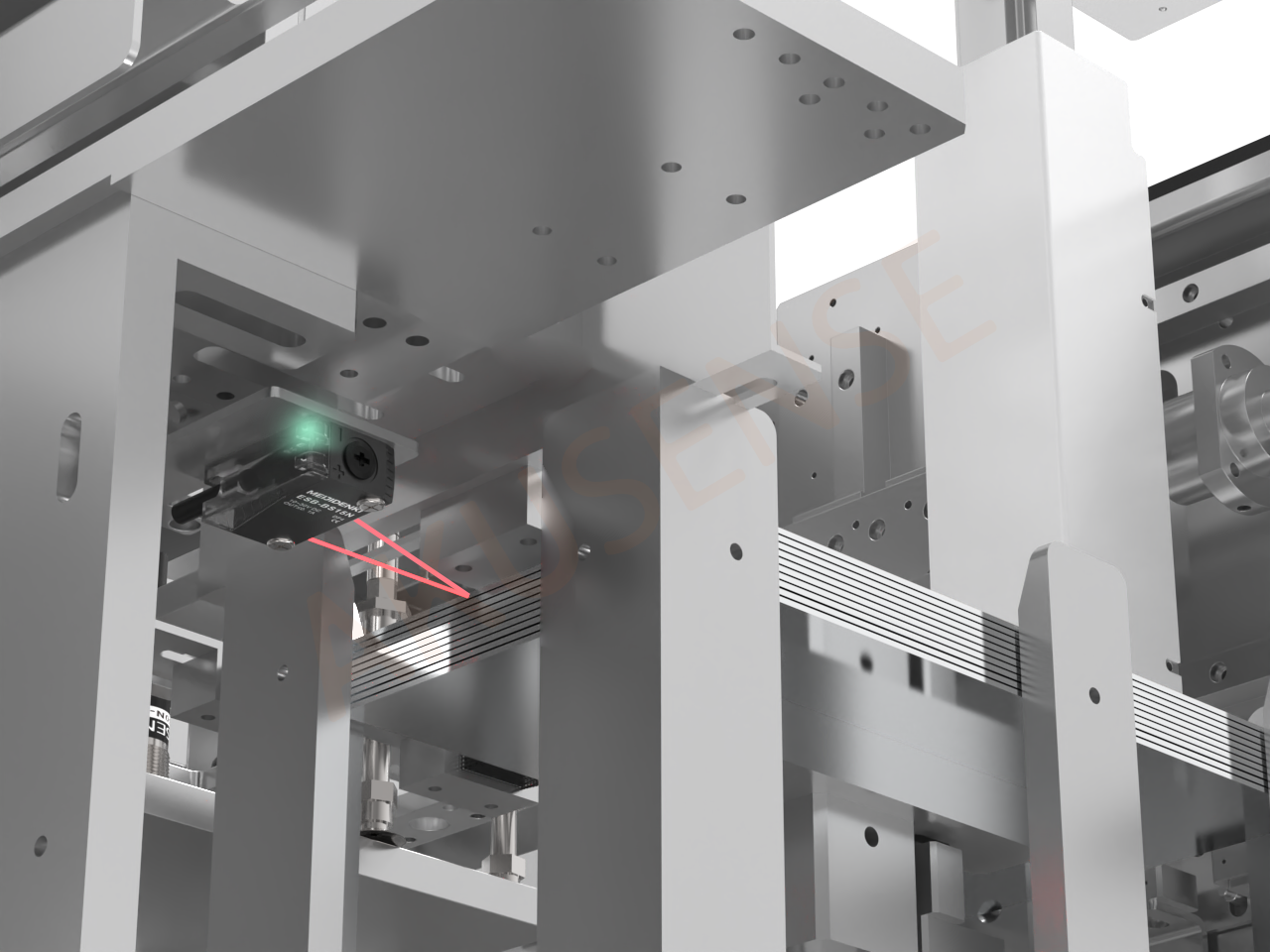

10 Check whether the battery is present

ESB-BS15 photoelectric sensor

Application scenarios:

Detect the pressure during lamination to ensure that the pressure during the lamination production process meets the set requirements

solution:

1. Using the Akusense digital display pressure sensor MQ-10 series to provide high-precision air pressure measurement results, with values accurate to several decimal places.

2. Simple structure, long service life, easy to use without complicated operations

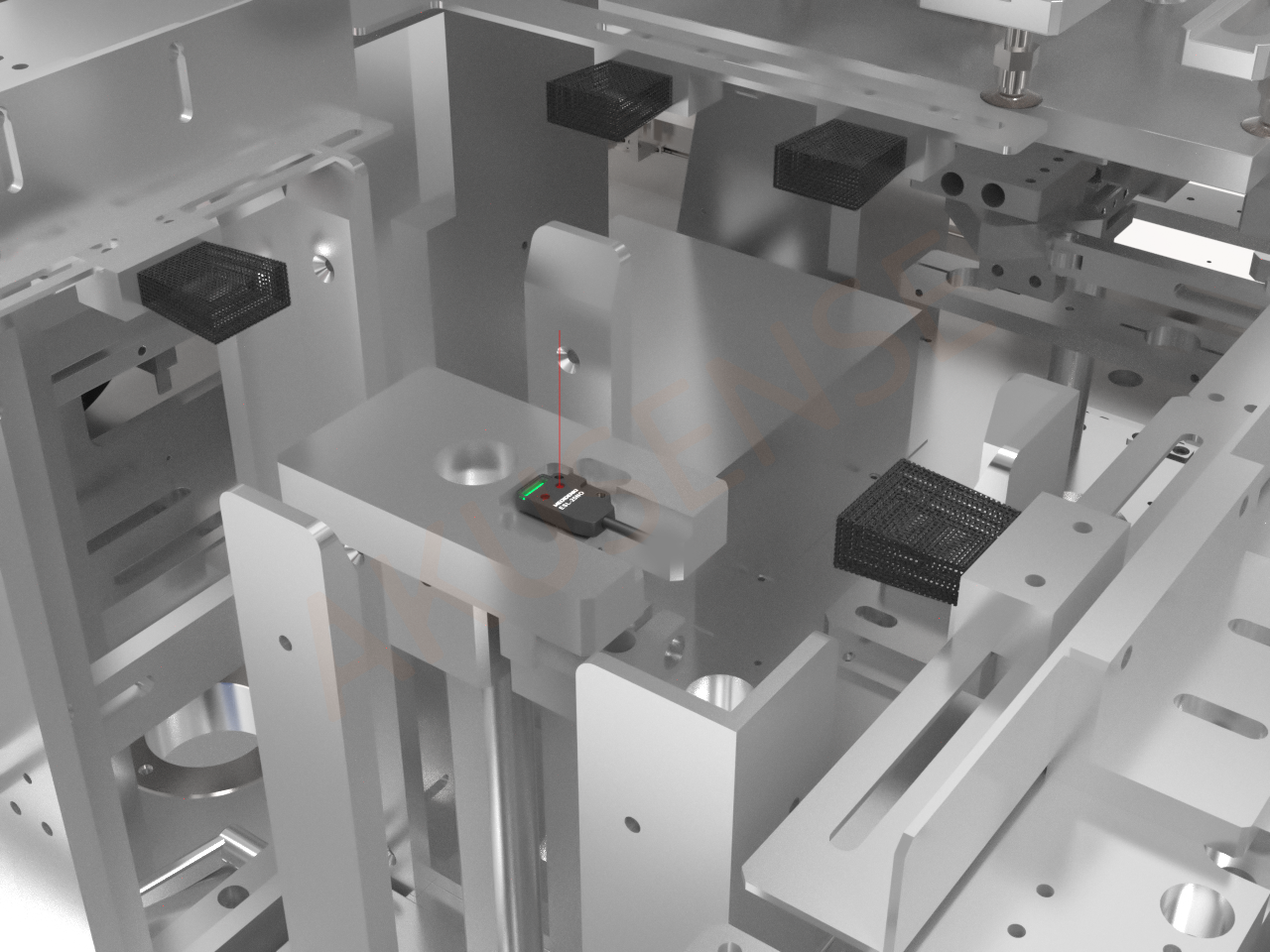

11 Monitoring of remaining material on pole piece loading

Ultra-thin Optoelectronics ESL-25 Series

Application scenarios:

Detect whether there is a pole piece in the pole piece material box. When the pole piece material is consumed, the sensor will send a signal in time to drive the equipment to load the material.

solution:

1. Using ESL series ultra-thin photoelectric sensors and 3.5mm ultra-thin design to effectively solve the equipment’s “space anxiety”

2. Ultra-thin and tiny size, with built-in positioning holes for easy installation.

3. Protection grade IP67, superior mechanical properties

+86 18188641602