Lithium battery front-end process - the process flow of the coating machine and the application of sensors on the coating machine

Lithium battery front-end process - the process flow of the coating machine and the application of sensors on the coating machine

Lithium battery front-end process - the process flow of the coating machine and the application of sensors on the coating machineWorking principle of coating machine

The rotation of the coating roller drives the slurry, and the amount of slurry transfer is adjusted by adjusting the blade gap. The rotation of the back roller or coating roller is used to transfer the slurry to the substrate. According to the process requirements, the thickness of the coating layer is controlled to meet the requirements. weight requirements, and at the same time, through drying and heating, the solvent in the slurry spread on the substrate is removed, so that the solid material adheres well to the substrate.

As the most basic and core link in battery cell manufacturing, coating plays a ballast role in the consistency and reliability of finished battery products. In order to ensure production efficiency and quality, the coating machine equipment is required to be highly uniform in coating and capable of automatic roll change at high speeds without stopping the machine. The application of sensors can well assist the coating machine in achieving precise control.

01 Ingredients

The vacuum mixer mixes the positive and negative electrode materials evenly and then stirs them into a slurry.

#Temperature Sensor

Control the temperature of the stirred slurry

#diffuse reflection ultrasonic sensor

Detect slurry level

02 Coating

In the entire process flow, the coating link is the most important link, which directly determines the quality of the production materials. Here we introduce to you three types of coating machines.

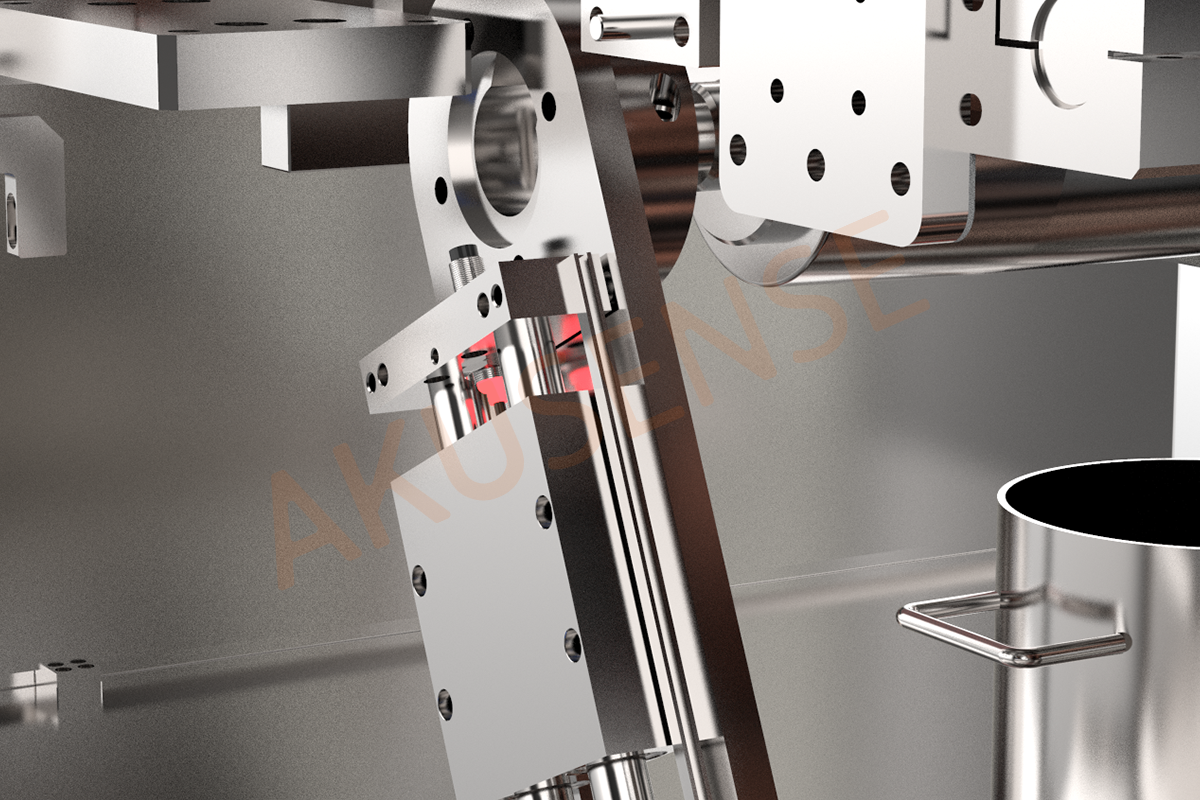

① The role of the sensor in the blade coater

After applying the paint to the paper surface, scrape off the excess paint and smooth the surface of the coating.

#Tilt sensor

Control the inclination angle of the scraper pressure plate, and control the angle of the scraper through the pressure plate to achieve a suitable working angle.

#proximity switch

Mainly detect whether the locking handle is screwed in place.

#Photoelectric sensor/proximity switch

Used to detect the up and down movement of the cylinder connecting rod to limit the position.

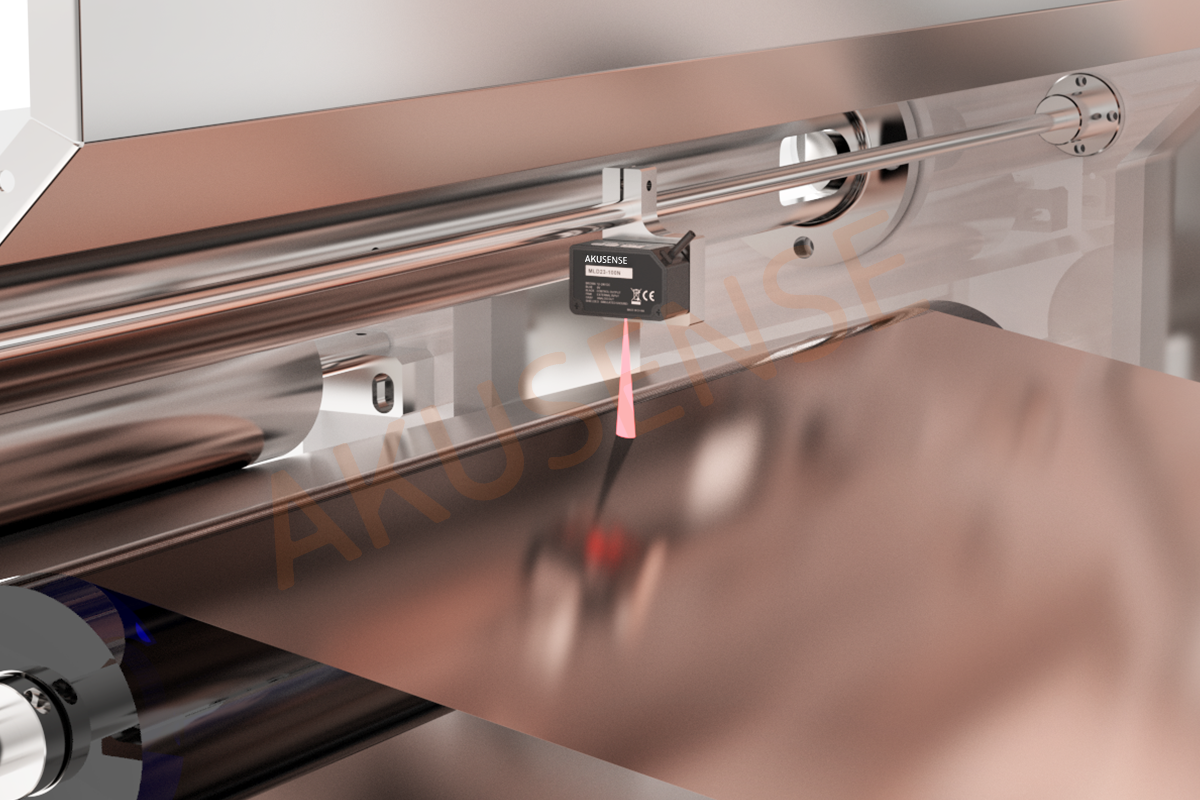

② Application of sensors in roller transfer coaters

The rotation of the coating roller drives the slurry, and the amount of slurry transfer is adjusted through the scraper gap, and the rotation of the back roller and the coating roller is used to transfer the slurry to the foil to form a coating.

#Photoelectric Sensors

Used to detect the presence of slurry

#laserdisplacementsensor

Used to detect whether the height of the material reaches the standard after applying the slurry.

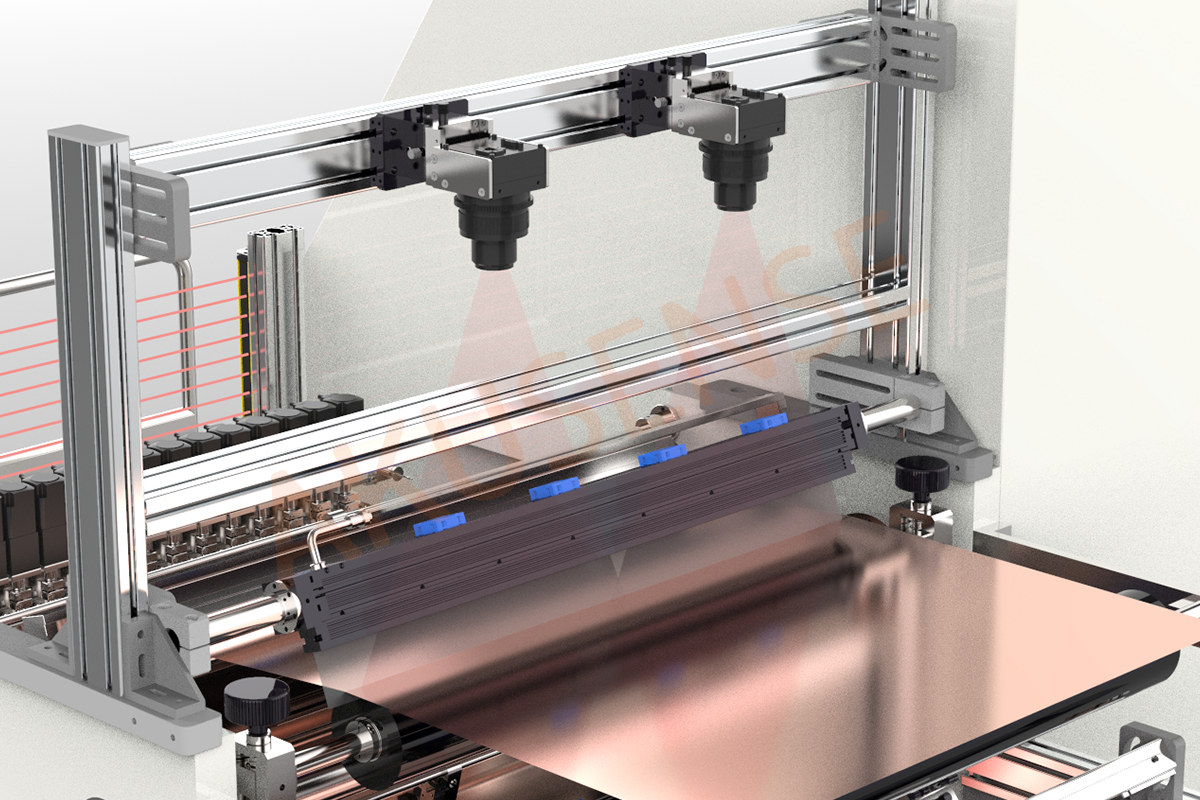

#deeplearningcamera

Detecting surface defects of pole pieces after rolling

For example: some pole pieces may have bubbles, wrinkles, dust, larger lint, etc. on their surface.

#Correction sensor

Detect the positional deviation of the electrode sheet after roller coating

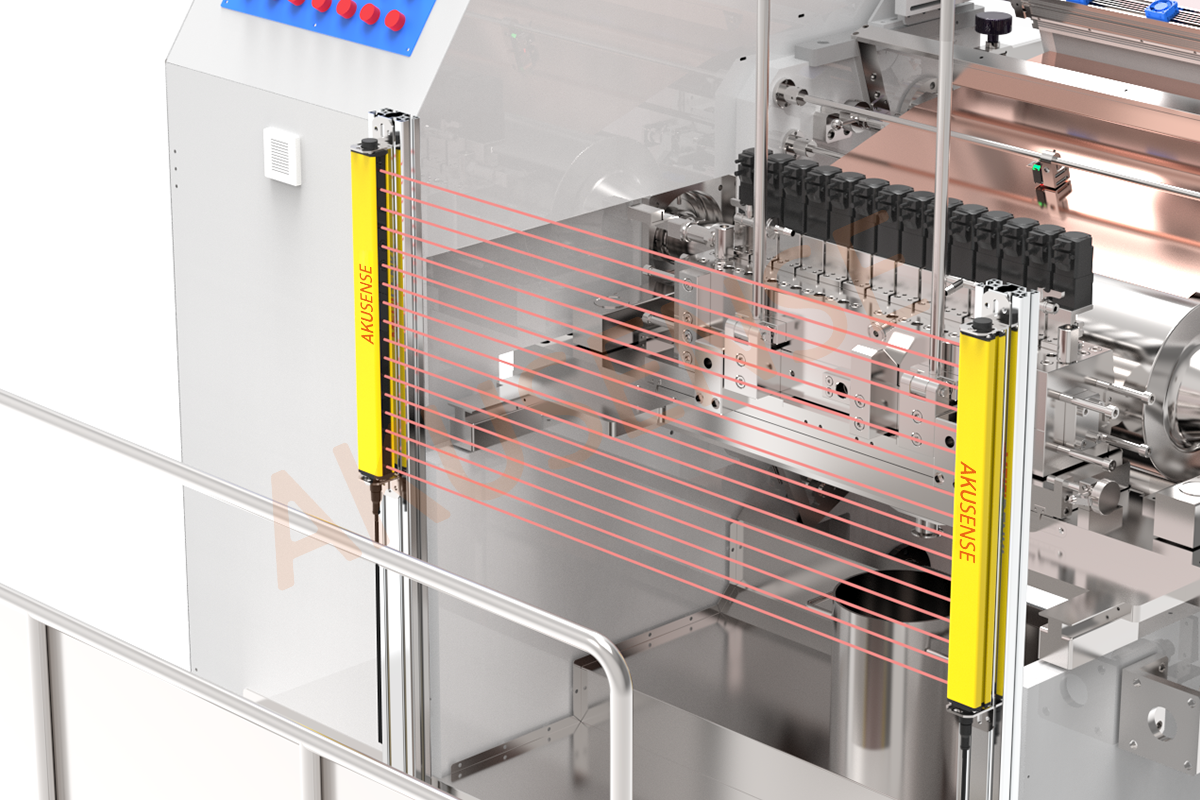

#safetylightcurtain

Installed on both sides of the safety door of the coating machine for safety protection

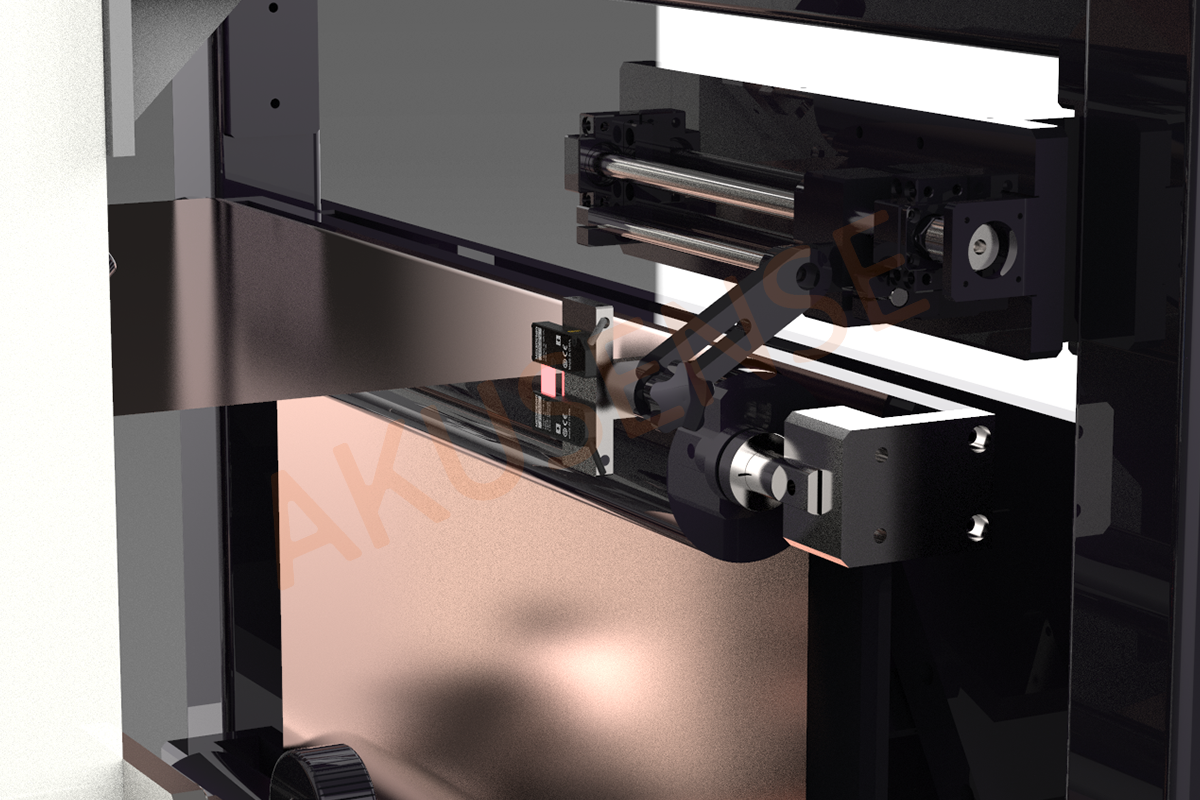

③ Application of sensors in slot extrusion coating machines

The coating liquid is extruded and sprayed along the gap of the coating die under a certain pressure and a certain flow rate, and then transferred to the substrate.

#Photoelectric Sensors

Check the presence of slurry

#Correction sensor

Detect the positional deviation of the electrode sheet after roller coating

#colorconfocalsensor

Used for precision measurement, mainly to detect the distance between the rollers of the slit extrusion coating machine to ensure uniform coating height.

#obstacleavoidanceradar

Used for area division, safe obstacle avoidance, and planning distance that prohibits people from approaching the coating machine

03 dry

#Temperature Sensor

The drying box is electrically heated, with uniform heating, precise temperature control and rapid drying.

04 Correction control and winding

Ensure the linear movement of materials, ensure that the coils and materials are accurately and smoothly processed during the entire processing process, and the winding and slitting are neat.

# Correction sensor

(1) Detect the movement trajectory of the roller and monitor in real time whether there is any deviation

(2) When detecting the roll material, is there any offset in the material?

#Slot switch

Mainly used for limit correction and drive guide rail movement

# Color Standard Optoelectronics

Detect the gold marking position on the pole piece

+86 18188641602