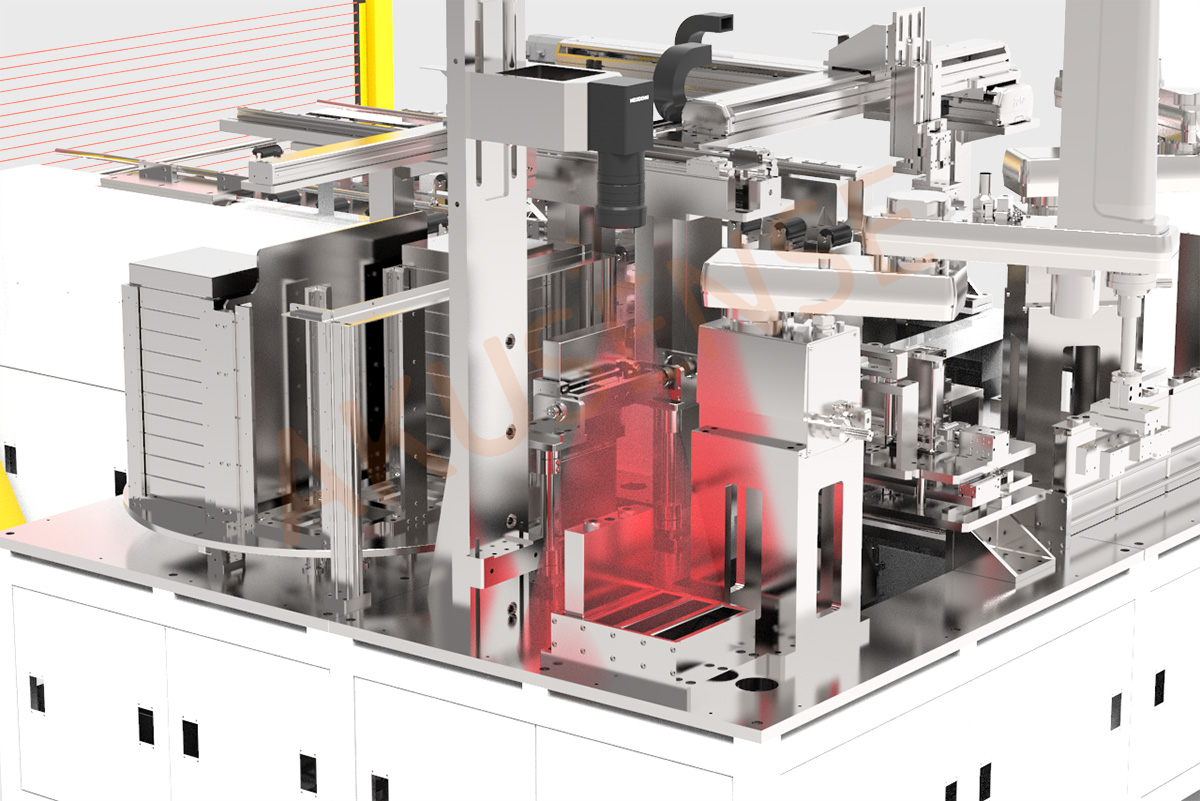

Empowering the intelligent manufacturing of lithium batteries, sensors can be used in housing devices like this

Empowering the intelligent manufacturing of lithium batteries, sensors can be used in housing devices like this

Sensor selection in the lithium battery industry is a complex task, but it is also relatively typical and representative, covering everything from ordinary trough lighting, photoelectric sensors, proximity switches and magnetic sensors to smart code scannSensor selection in the lithium battery industry is a complex task, but it is also relatively typical and representative, covering everything from ordinary trough lighting, photoelectric sensors, proximity switches and magnetic sensors to smart code scanners, safety light curtains, and visual inspection The application range can be said to be very wide. There are many difficulties, such as highly reflective workstations, small installation spaces, extraction of special characters, and entry of various QR codes.

AKUSENSE focuses on creating a complete set of application solutions for sensors in 3C and lithium battery equipment. In previous articles, we shared with you the coating machine in the front-end process of lithium batteries, cell tab cutting, and the lamination machine and winding machine in the middle process. , laser welding, laminating machines for back-end processes, smart warehousing, etc. There are a large number of implementation cases.

In this issue, let’s share with you the application of sensors on lithium battery housing equipment.

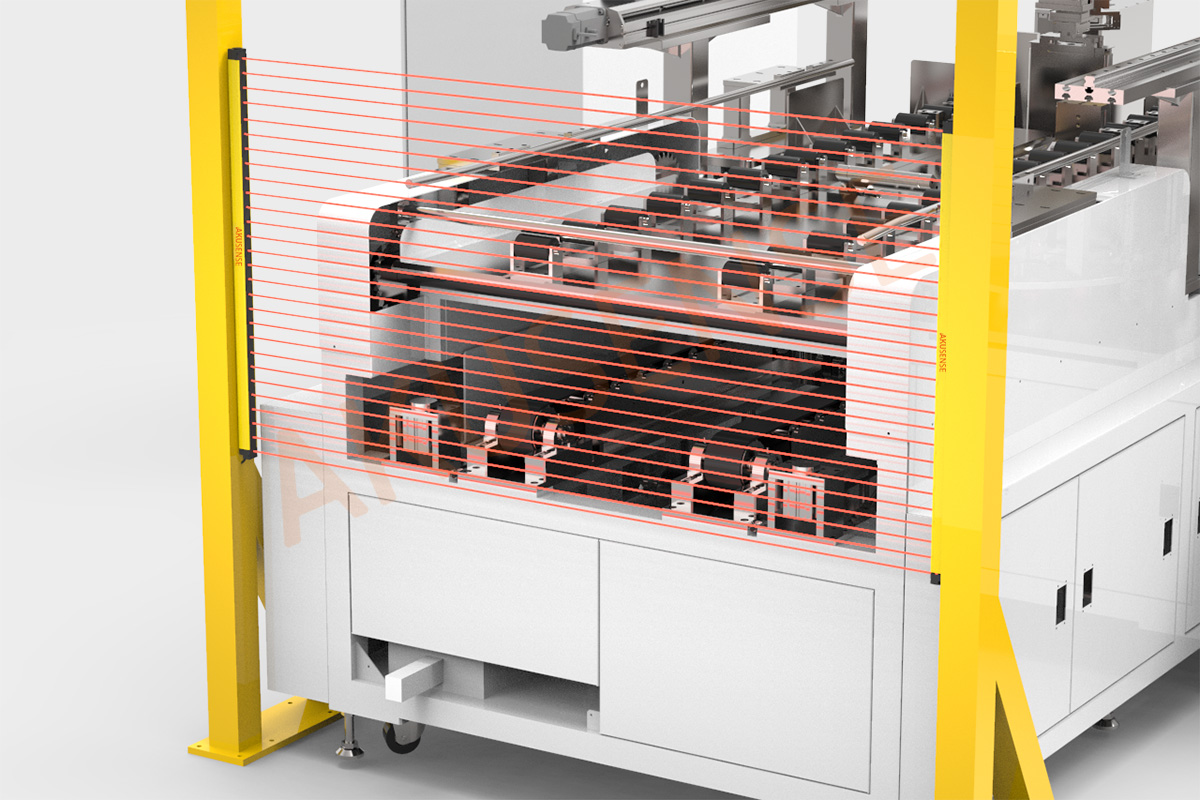

01 Protection of loading and unloading areas of battery case trays

There is a risk of mechanical movement and injury in the loading area, so the regional safety obstacle avoidance light curtain BSL40-T3206NC is used. When someone or a car enters the protection range, some mechanisms will stop to avoid mechanical injury.

02 Loading and unloading trolley position sensing

The proximity sensor TLN12-08NO is used. It is an enhanced distance proximity sensor with twice the detection distance than the standard product. It can effectively solve the problem of conflict in the work installation space. When the trolley reaches the loading position, the sensor gives a signal to drive the belt conveyor. The feeding tray enters the work station.

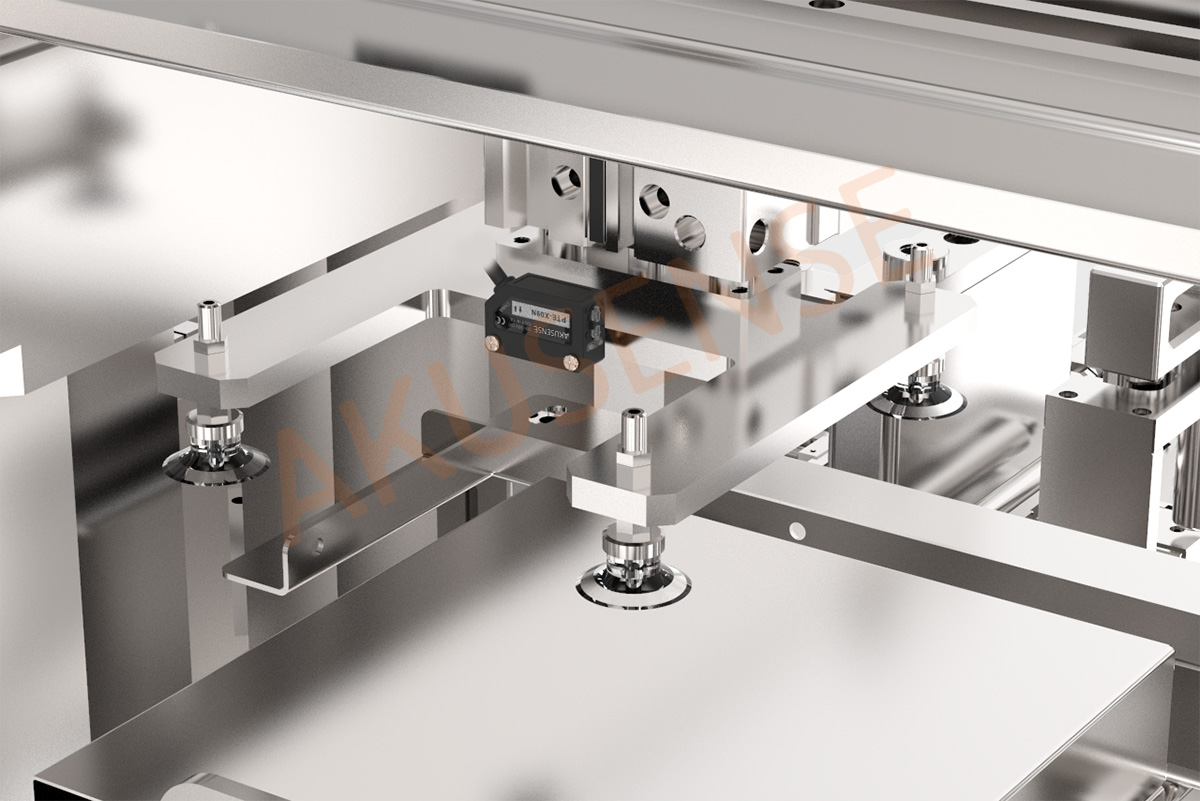

03 Aluminum shell dust removal and transfer module

PTE-X09N is installed at the clamping jaw station and is used to detect whether there is material at the clamping jaw. The manufacturing process of limited reflection effectively avoids misjudgments caused by some highly reflective objects and can stably output the status of the current workstation.

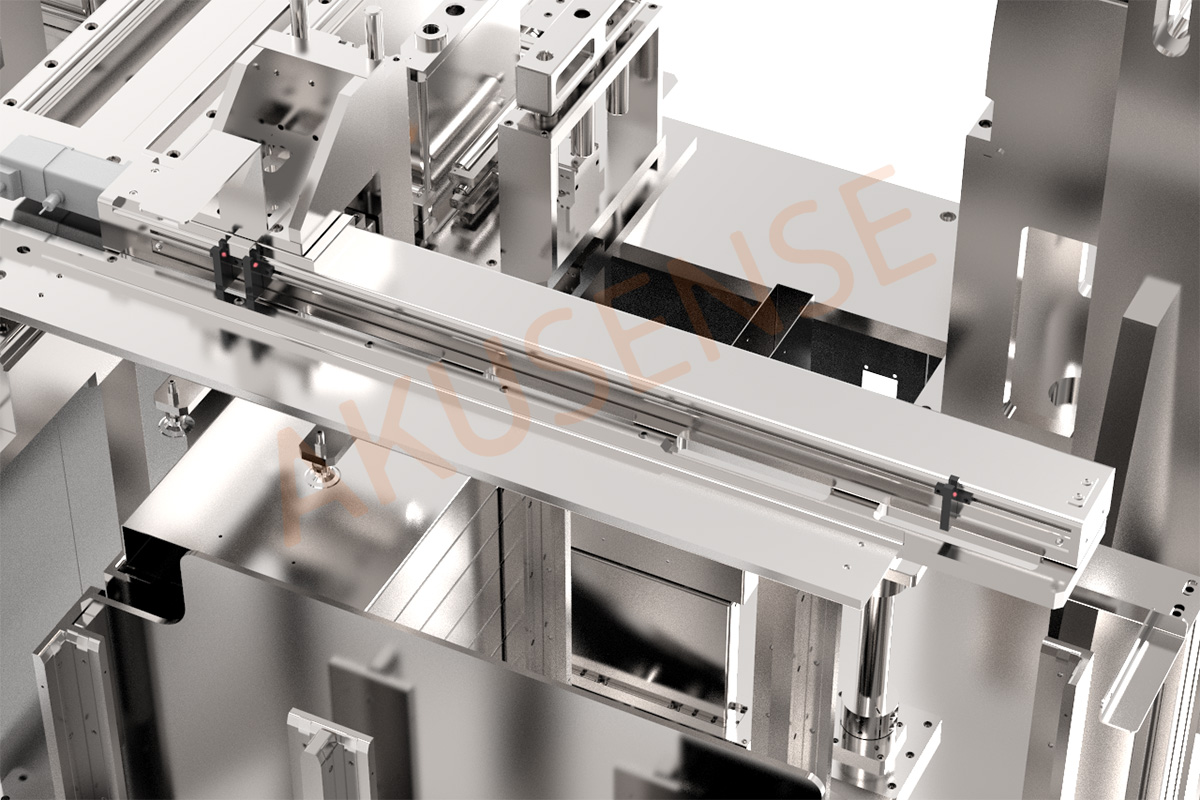

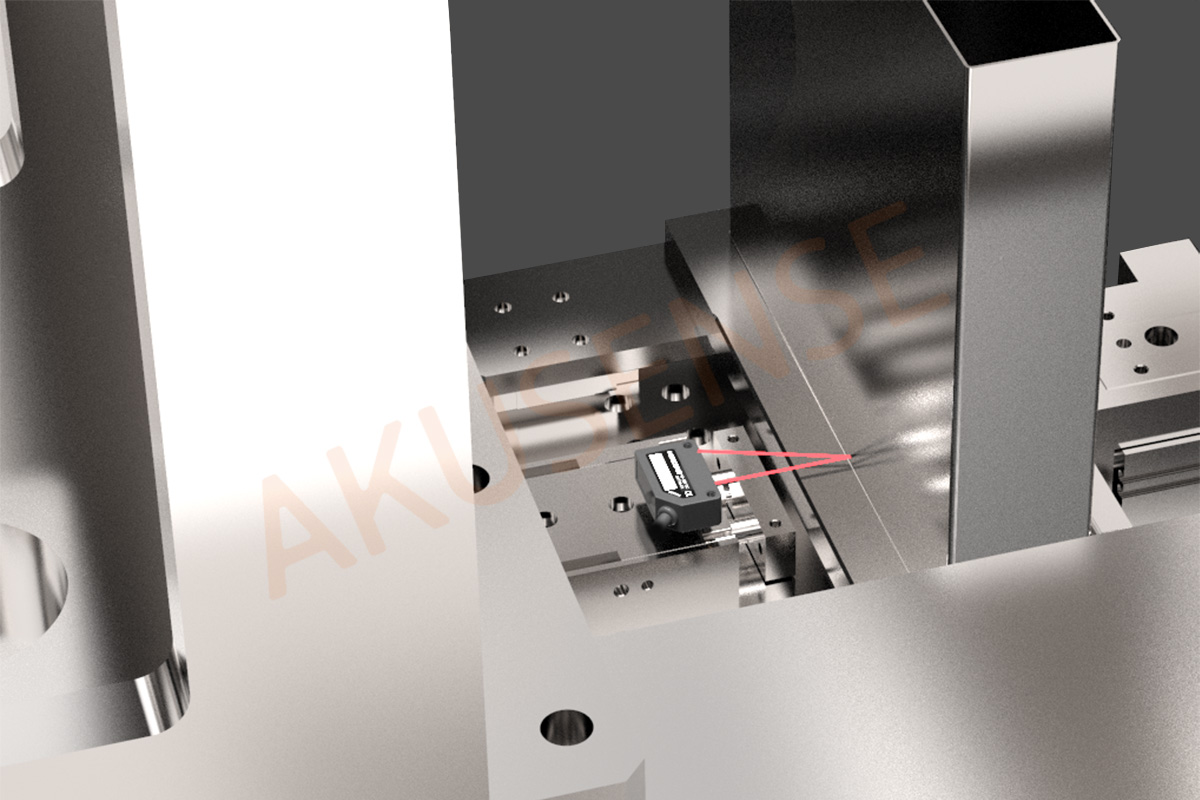

04 Tray transfer module

The groove type ST-303N-W is used to detect the empty material tray after the material has been taken out, and the integrated chip design allows Meiji's groove type sensor to exhibit superior mechanical performance, with a repeatability accuracy of 0.01mm.

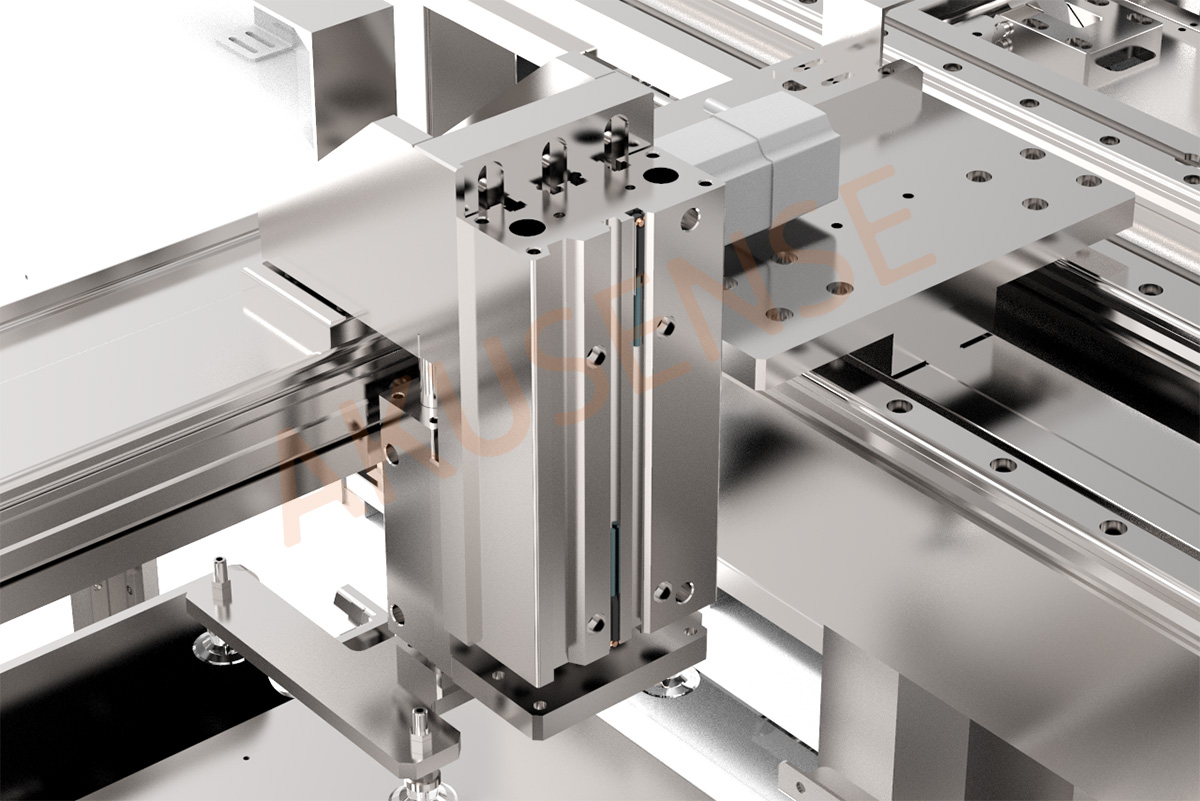

05 Cylinder station status monitoring

Two magnetic sensors MR-C8-C-S are installed to detect the status of all cylinders. One detects the extended status and the other detects the retracted status. The response is fast and the accuracy reaches the micron level.

06 Reverse transfer module

The battery case after dust removal is grabbed by the robot and placed at the workstation of the case insertion module. At this time, the bottom sensor ESB-V30N detects the position and triggers the next action cylinder to push the processed battery core into the case to complete the process. Workstation action. This sensor uses an infrared light source, which has a certain inhibitory effect on visible light. It also has strong background suppression performance and good anti-interference ability, making its detection in the device efficient and stable.

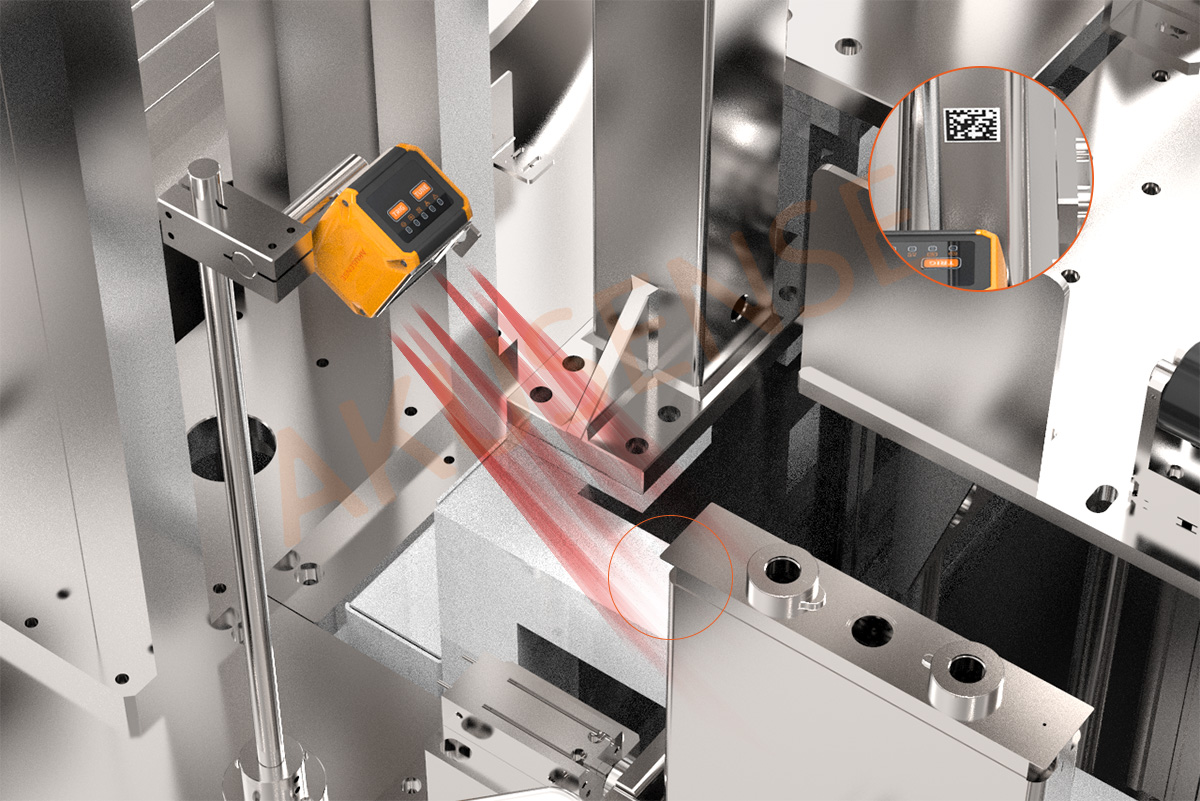

07Reverse transfer module

Here, the battery needs to be inverted 90 degrees, and the QR code needs to be recognized to facilitate recording and traceability. The new RCD-AI100-120W smart code reader is used to support the identification of DPM codes of different materials. It can also effectively read codes in complex situations such as damaged barcodes, low contrast, poor printing quality, etc. The 4 sets of light sources are independently controlled and support a variety of The combination of light angles, flexible configuration of luminosity, and polarization options are provided to easily meet the code reading needs in complex scenes.

08 Defect detection

The visual inspection system detects defects in battery appearance (scratches, exposed metal, wrinkles, bright spots, particles, powder loss, edge damage, pole piece perforations, pole piece connections, dark spots, bright spots, dry material spots, foreign matter It not only improves work accuracy and efficiency, but also reduces labor costs and ensures product quality and yield rate.

+86 18188641602