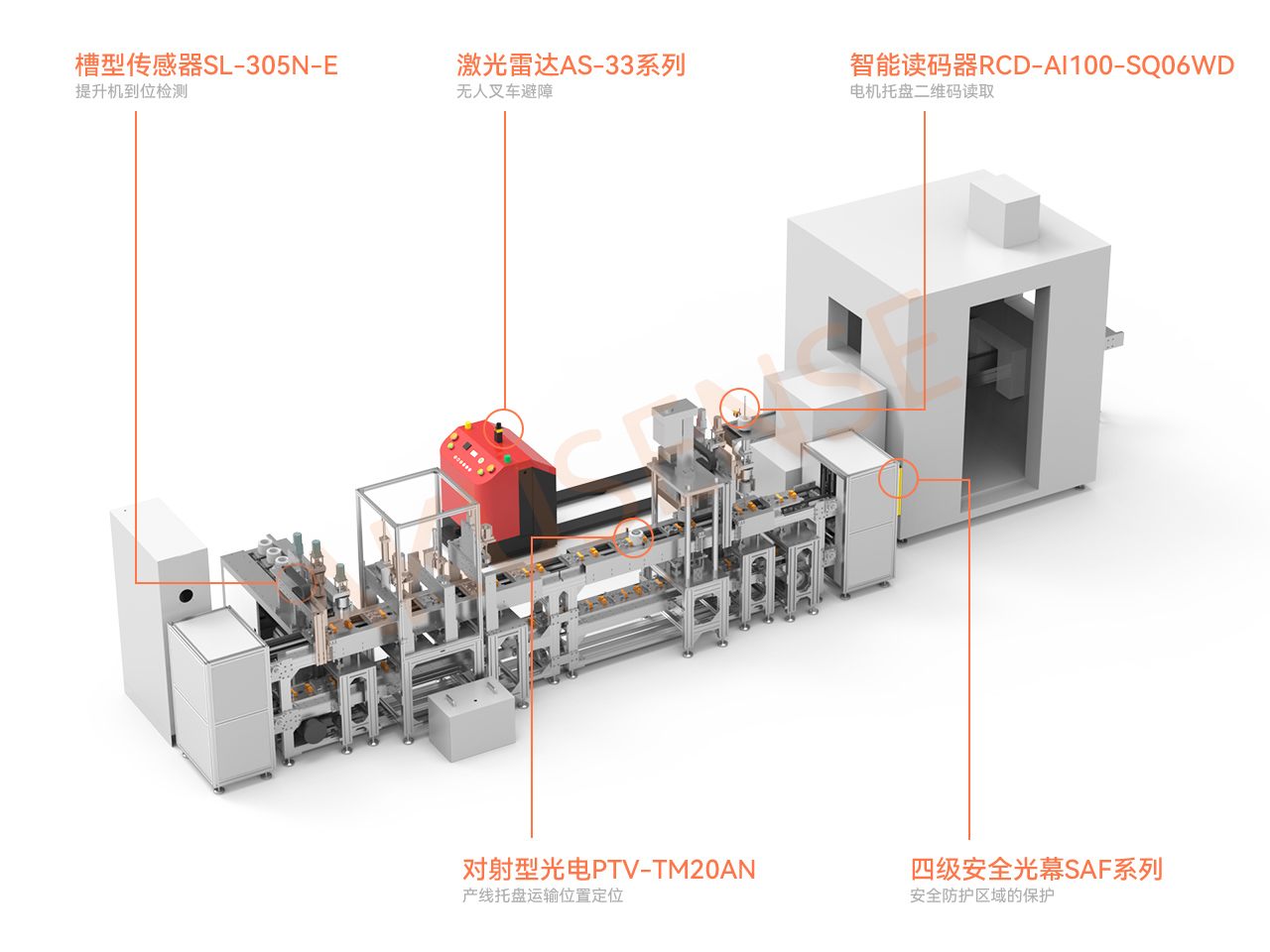

Lithium battery automatic production line

Lithium battery automatic production line

The increase in production capacity of lithium battery automatic production lines is inseparable from these sensorsThe TWh era is coming. The jump in production capacity and increasingly refined market requirements have caused power battery companies to put forward new requirements for equipment companies. Equipment companies must not only ensure high-quality and stable delivery of equipment, but also cooperate with the diversified innovation and extreme intelligence of power batteries. Process innovation in core manufacturing processes can effectively improve product quality and reduce defect rates.

In the past, production line intelligence mostly referred to stand-alone intelligence, which meant making the process more intelligent by improving specific processes, such as introducing multi-jointed robots in module and PACK lines to perform handling, loading and unloading, and coating. Gluing, stacking, welding, sorting, cleaning, boxing, locking, testing, packaging and other operations replace the previous manual operations. However, this is only the intelligence of a single machine. For the entire production line, it can only The purpose is to improve the productivity of a single-stage process.

As a result, it has become inevitable for the lithium battery equipment industry to move from stand-alone intelligence to whole-line intelligence. The whole-line intelligence in the lithium battery industry refers to embodying the concepts of automation rate, reliability, flexibility, stability and data management in the production line during the production process of power batteries to truly realize unmanned production.

To realize the intelligence of the whole line, it is inevitable to be inseparable from the soul of automatic intelligent control - sensors. This issue has sorted out the classic applications of sensors in the lithium battery automatic production line based on on-site applications.

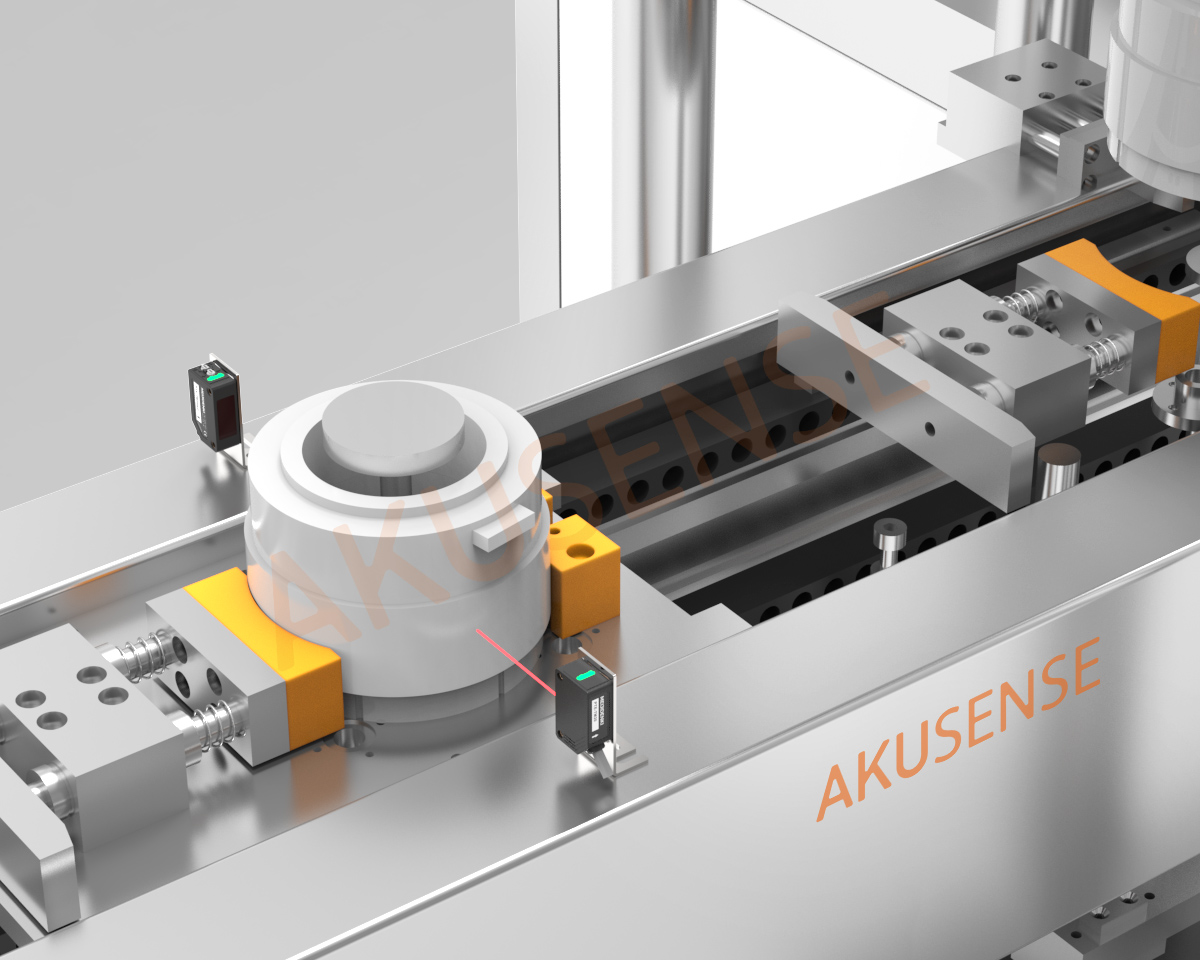

01 Positioning of production line pallet transportation

Through-beam photoelectric sensor PTV-TM20AN

Scenario requirements: During the flow process of the line body, it plays the function of intercepting and waiting for the back-end pallet.

Difficulties in application: Due to vibration and other factors when the line body is running, it will affect the transmitting and receiving ends of the sensor (the beam cannot be aligned). In the past, misjudgments often occurred, and the operator had to reset, affecting production efficiency.

solution:

1. Adopting the through-beam photoelectric PTV series, this newly upgraded infrared through-beam photoelectric has been optimized in terms of software and hardware to deal with the problem of equipment vibration, making the sensor's emission and reception angle larger; making the sensor from installation and debugging It is more convenient, stable and efficient to use.

2. The product uses infrared light source

3. Optimize and upgrade the chip, which has better through-beam photoelectric performance than before.

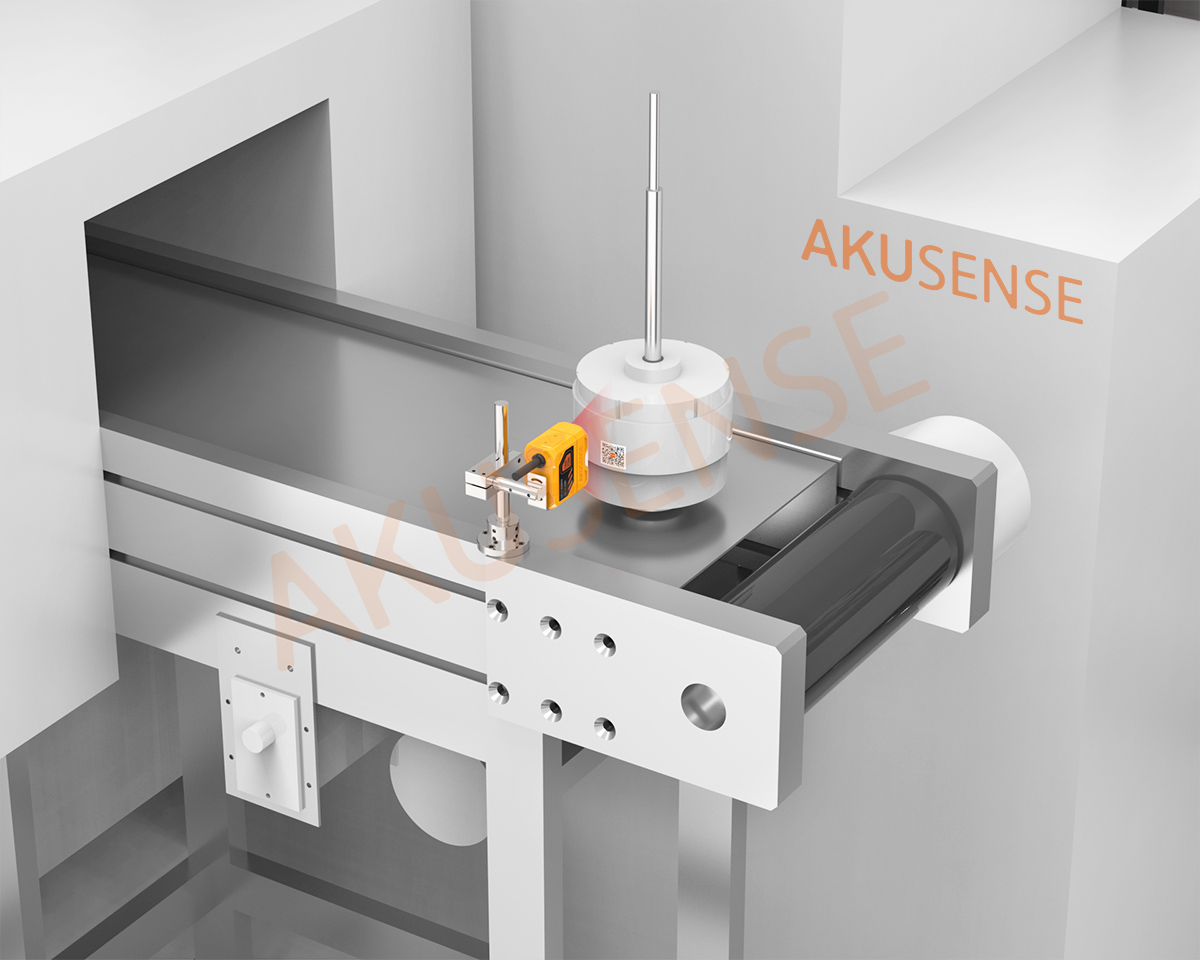

02 Motor tray QR code reading

Intelligent code reader RCD-AI100-SQ06WD

Scenario requirements: Scan the code before the pallet enters the back-end process, and enter the information into the warehouse

Solution: QR code recognition of multiple types and different coding processes, liquid zoom technology for quick focusing

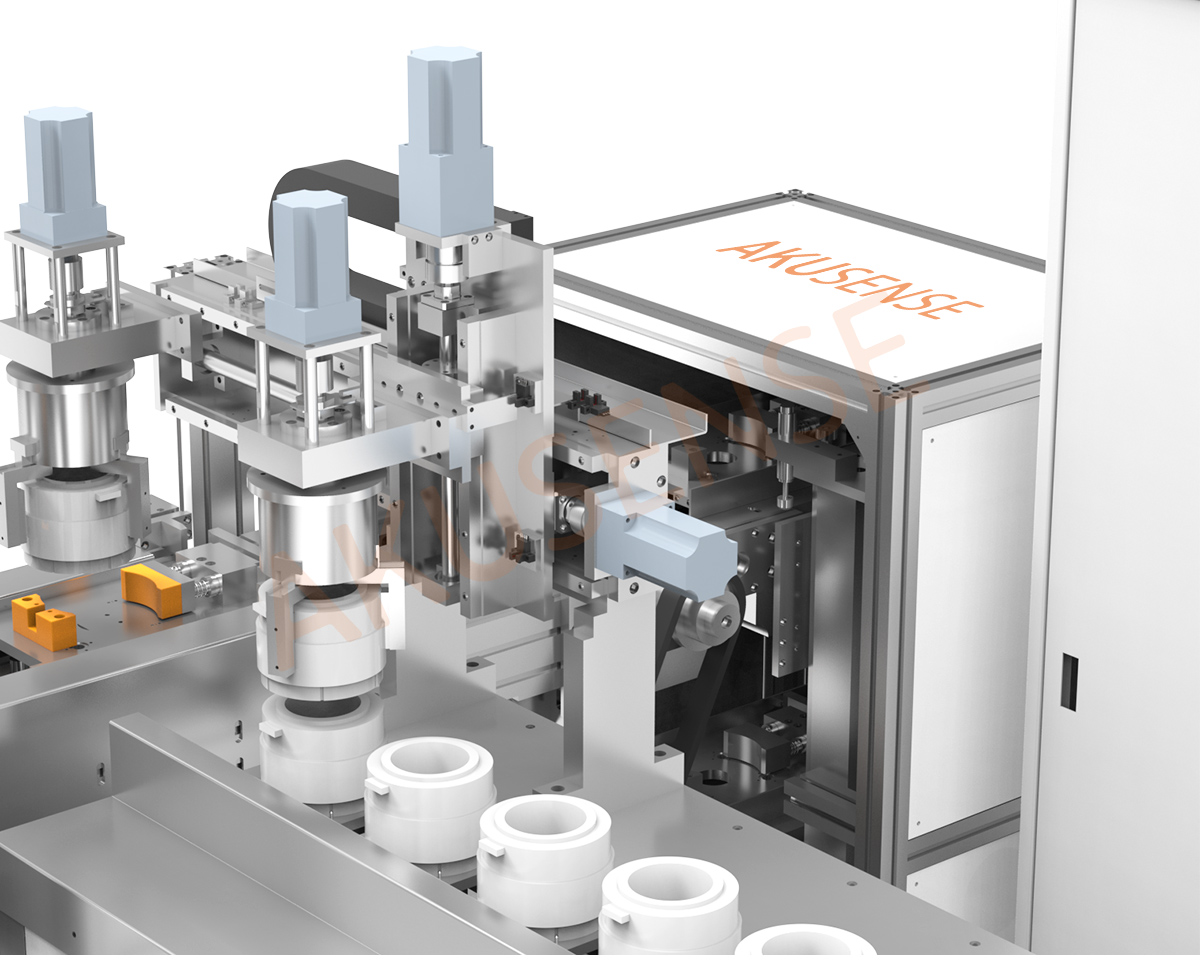

03 Safety protection areas, injuries to sports mechanisms, etc.

Protection of high-risk areas

Safety light curtain SAF series

Scenario requirements: Multiple areas require security protection, and the regional protection distances are different.

Detection difficulties:

1. The protection distance of some larger equipment protection areas is far away, and ordinary light curtains cannot meet the requirements.

2. The accuracy required can reach the level of protecting small objects.

3. Stable safety signal output is required to prevent the loss of safety functions even if the light curtain fails and achieve multiple protections.

solution:

Using the four-level safety light curtain SAF series, the ultra-long protection distance is 40 meters and the detection accuracy is high.

Multiple optical axis spacing can be selected to protect fingers, and it is also equipped with dual independent OSSD outputs, which can independently drive the lower safety relay, etc. The dual outputs do not interfere with each other to improve safety performance, and have stronger anti-interference capabilities, including electromagnetic interference and optical interference.

04 Hoist in place detection

slot sensor

Scene requirements: Real-time control of the origin and extreme position of the equipment motion module

Solution: We have a rich product line of groove sensors and chip integration solutions, which enable them to have a repeatable positioning accuracy of 0.01mm, making the position control of the equipment more precise; product appearance designs are diverse, including F/T/R/L/K There are 12 different shapes, various installation methods, and the slot width covers 5mm-120mm, which can meet the installation requirements of different detection positions on the equipment.

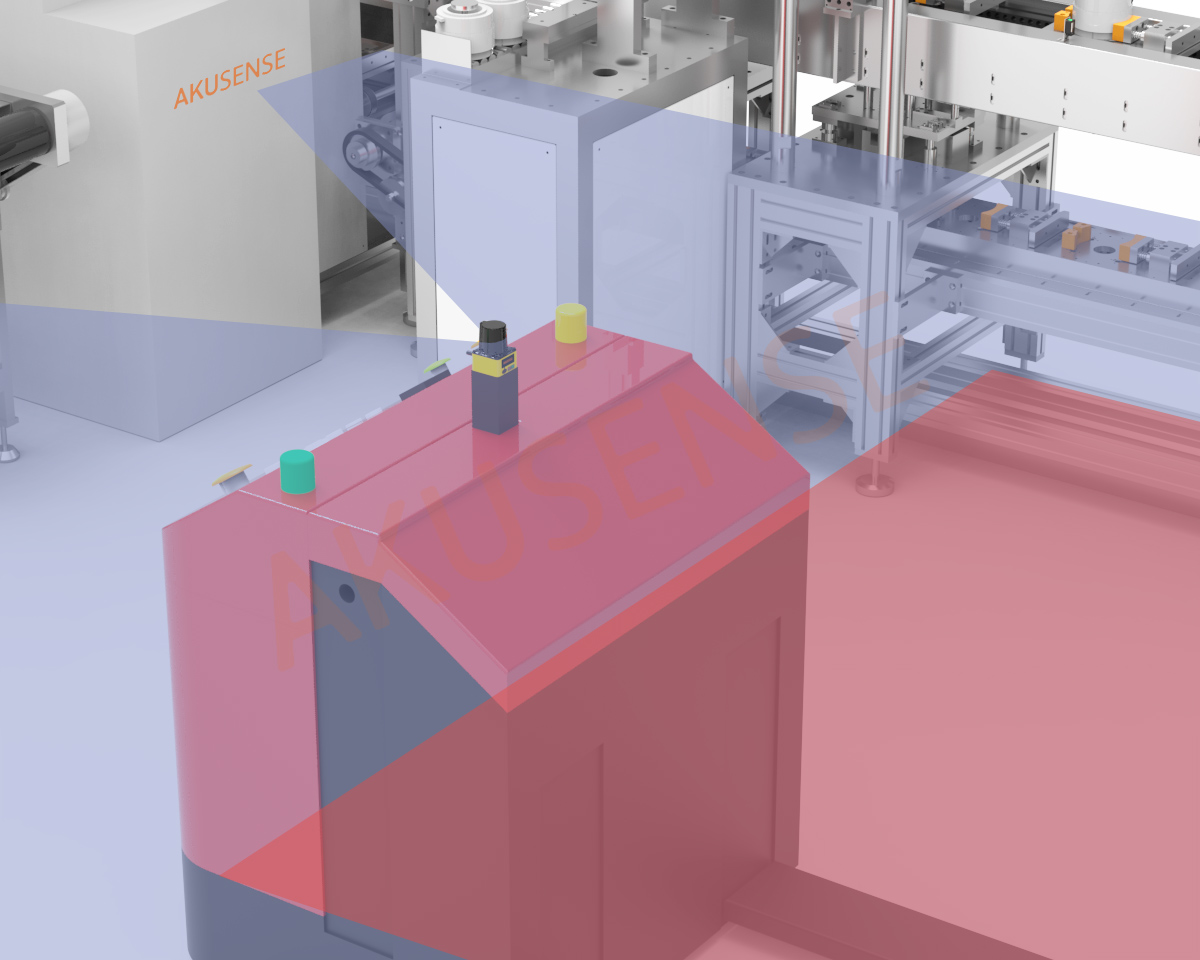

05 Unmanned forklift obstacle avoidance

LiDAR AS-33 Series

Scenario requirements: The route between the workshop→packing area→finished product warehouse is long, and the power battery is heavy. Unmanned forklifts need to be used to improve internal logistics efficiency; sensors are needed to map the structure and topography of the workshop working environment, and to detect nearby people and objects. Make an emergency stop to avoid danger.

Detection difficulties:

Adapt to the needs of loading and unloading forklifts for various equipment

The operating space of unmanned forklifts is compact, and the radar size also needs to be smaller and more precise.

Need to adapt to work scenarios where humans and machines are mixed and multiple vehicles are mixed.

Real-time and accurate distance measurement to ensure high-precision pickup safety

solution:

A typical application is obstacle avoidance radar AS-33C, which sets the area that needs protection and gives alarm signals (attention, early warning, alarm). The software clearly displays information about people and objects within the detection range. and navigation radar AS-100C, realizing unmanned transportation and automatic loading and unloading of highly intensive processes. Single-layer panoramic scanning lidar with diffuse reflectance (RSSI) measurement capability. The measurement data output is the distance and RSSI composite measurement data at each measurement angle, and the scanning angle range reaches 360°

+86 18188641602