Application of AKUSENSE in liquid filling machines

Application of AKUSENSE in liquid filling machines

Hygienic safety is a very important requirement for sensors used on edible oil filling machines.Hygienic safety is a very important requirement for sensors used on edible oil filling machines.

This means we need to choose materials that are resistant to corrosion and high-pressure washing, have a high degree of protection and mechanical stability, and have sensors that can quickly return to normal working condition after cleaning.

In the modern packaging industry, the fully automatic liquid filling machine is an indispensable automation equipment. It integrates multiple functions such as automatic feeding, automatic bottle feeding, automatic clamping, automatic quantitative filling and automatic bottle discharging. The high-precision measurement and control system realizes the efficiency, accuracy and continuity of the liquid product filling process, significantly improves production efficiency, reduces labor costs, and ensures the consistency and stability of product quality. At the same time, its flexibility and scalability also meet changes in different products and production needs.

AKUSENSE plays a decisive role in the fully automatic liquid filling machine equipment. Through the comprehensive application of various sensors, the fully automatic liquid filling machine does not require manual operations such as placing bottles, taking bottles, and changing bottles during the filling process. They are like Intelligent eyes and brain accurately monitor and control every filling link to ensure the accuracy and efficiency of liquid filling.

In this issue, Xiao Ming will share the application of AKUSENSE~

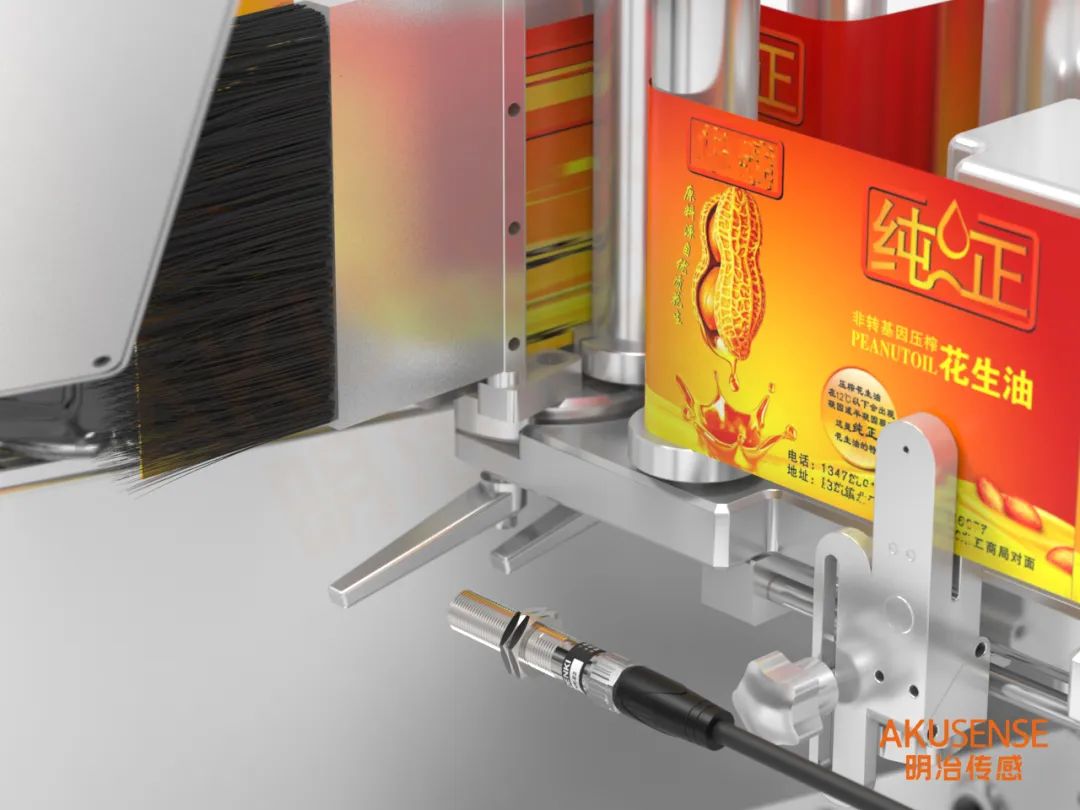

01 Test the glue brush

IP69K proximity sensor TPF12-04NR-E2

Application scenarios:

Empty oil bottles need to be pasted with wrapping paper on the bottle, and a robot needs to use a brush to apply glue on the bottle first. A sensor needs to be installed here to sense the brush and stop it to avoid overflowing of glue.

1. The sensor detection needs to be accurate, otherwise the glue will be brushed too much, causing overflow and affecting product quality.

2. Hygiene and safety is a very important requirement. The sensor needs to be resistant to detergent corrosion and high-pressure cleaning; it must have high protection level and mechanical stability.

◀ IP69K protection level ▶

For the food industry, choosing sensors with IP69K protection level is not only a necessary condition to meet production needs, but also a strong guarantee for improving the market competitiveness of equipment.

The sensor with protection level IP69K ensures that the equipment can still operate stably in harsh cleaning and disinfection environments.

solution:

1. Use high positioning accuracy, reliable performance, switching frequency can reach 2000Hz, and fast response speed

2. It has a high protection level of IP69K, is waterproof and dustproof, and can quickly return to normal working condition after cleaning.

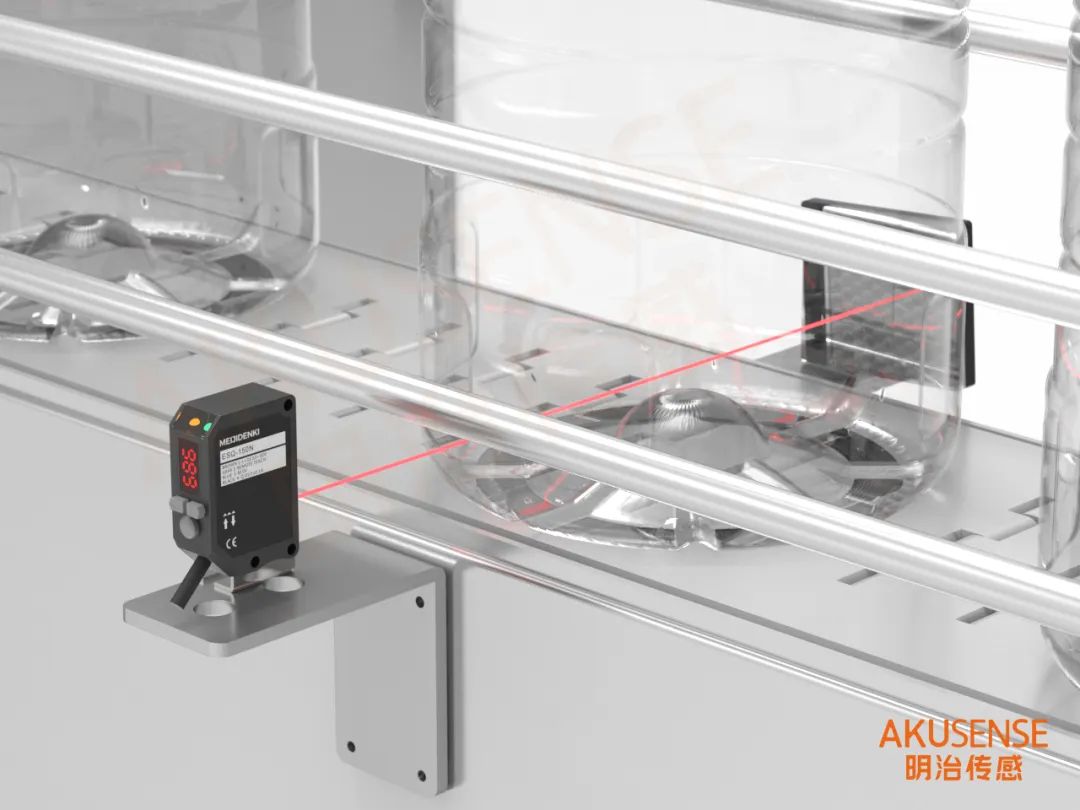

02 Check whether there are empty bottles

Laser sensor ESQ-150N

Application scenarios:

Detect whether the transparent oil can is in place on the assembly line. After it is in place, it outputs a switching signal to drive the equipment for edible oil filling operations.

1. The oil pot is a transparent body, and ordinary diffuse reflection photoelectric cannot detect it normally.

2. The body of the oil bottle is not flat, which has a certain impact on the detection.

◀ Transparent body detection type ▶

A high-precision sensor designed specifically for detecting transparent or translucent objects, which solves the problem of traditional photoelectric sensors being difficult to accurately detect transparent objects. Because of the high transmittance and low reflectivity of transparent objects, it is difficult for ordinary sensors to capture effective light signal changes.

Through the special lens reflective design and high-sensitivity detection technology, the transparent object detection photoelectric sensor can accurately capture the changes in the weak light transmitted or reflected by the transparent object, thereby achieving accurate and reliable detection.

Solution 1: Under longer distance detection conditions

1. Use the ESQ series of laser sensors, which adopt a retro-reflective detection principle and can automatically adjust the threshold according to changes in current light exposure. It is specially used for transparent object detection.

2. LED coaxial light source, easy calibration

Solution 2: Under close range detection conditions

1. Select the cylindrical proximity sensor CRF12-03NO series, which adopts capacitive detection principle, high positioning accuracy, reliable performance, switching frequency can reach 100Hz, and fast response speed.

2. It has IP67 protection level, good waterproof and dustproof performance, and can quickly return to normal working condition after cleaning.

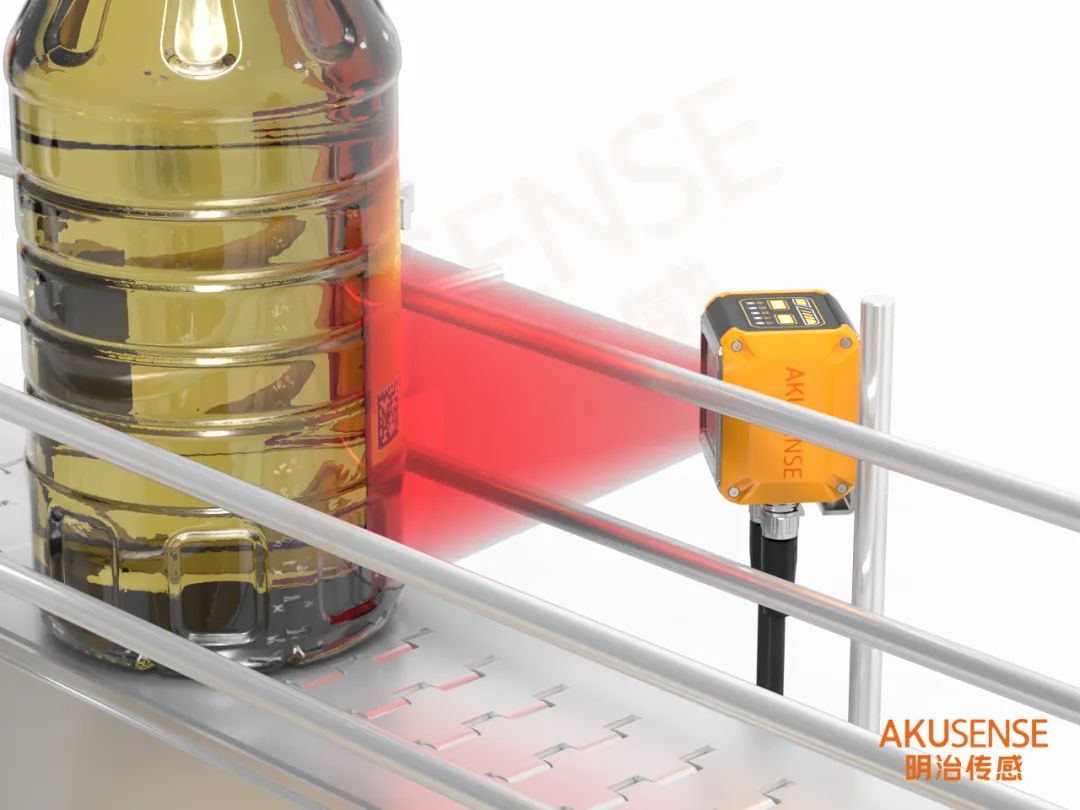

03 Check whether the bottle cap is present

Photoelectric sensor PTE-RM2

Application scenarios:

After the oil bottle is filled with edible oil, the robot will screw on the bottle cap and then flow into the next station through the assembly line.

Here you need to choose a photoelectric detector to detect the presence or absence of bottle caps. When there is a product without a cap, a signal will be given.

solution:

1. Use retro-reflective photoelectric sensor PTE-RM2 and dual LED indicator light design to clearly identify action conditions.

2. Resist strong light interference and still detect stably

3. The reflector is made of specific materials, and the shell is strong and not easy to break.

4. Dynamic filtering algorithm can easily achieve optimal detection results in various environments

04 Bottle barcode identification

Intelligent code reader RCD-AI100-X08WD

Application scenarios:

When the oil bottle is filled and flows to the discharge port through the transmission line, the barcode reader recognizes the barcode on the bottle and transmits it to the MES system.

1. The code reader is required to quickly identify the QR code on the bottle.

2. The light at the discharge port is dim, and a code reader is required to identify the QR code in a dim scene.

3. The width of the discharging flow line is wide, and the position of the bottle barcode may be deviated.

4. The plastic film on the bottle body is smooth and may be reflective.

Detection difficulties:

1. The body of the oil bottle is round, and the barcode position will be deviated, resulting in code reading failure.

2. Barcodes are recognized on the move, and there are certain requirements for the recognition speed of the code reader.

3. The barcode position is not on the outside. The barcode reader needs to be installed on the side and read diagonally.

solution:

1. Use the intelligent code reader RCD-AI100-X, equipped with a Cortex 4-core processor, with a single core up to 1.8GHz and a maximum reading speed of 60/second, which can stably detect high-speed moving objects.

2. Adopt a super flexible light source system, the red/white light can be customized according to the scene, and the 4 groups of light sources can be controlled independently, with high flexibility

3. Covers mainstream code reading distances, with a maximum reading distance of 1000mm and a maximum field of view of 480*300mm. Even if there is a certain deviation in the position of the material, the recognition effect will not be affected.

05 Monitoring the switch status of equipment safety door

Security door lock AR3 series

Application scenarios:

When the filling machine equipment fails, the staff needs to open the screen door for maintenance. It is required to install a safety door lock. When the screen door is open, the operation of the mechanical equipment must be stopped. The safety door lock is required to have high tensile strength when locked.

solution:

1. Choose the AR3 series of safety door locks with built-in 2/6 sets of contacts, with indicator lights and emergency unlocking functions, and a variety of operating keys.

2. Designed with PA66 flame retardant material, it can still operate stably in usage scenarios of -10℃-55℃

4. The internal hardware adopts precision design, and the forced pulling force strength is 1300N when locked.

5. IP67 high protection level, passed testing and certification by multiple agencies, ensuring effectiveness and lifespan.

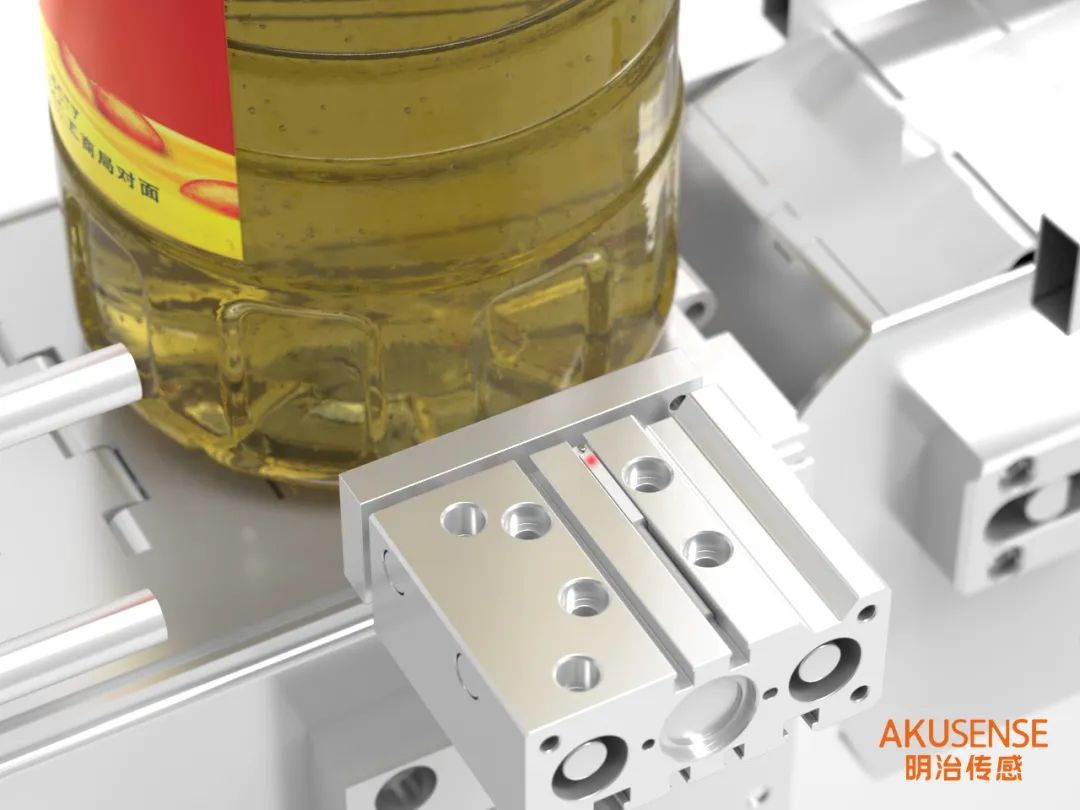

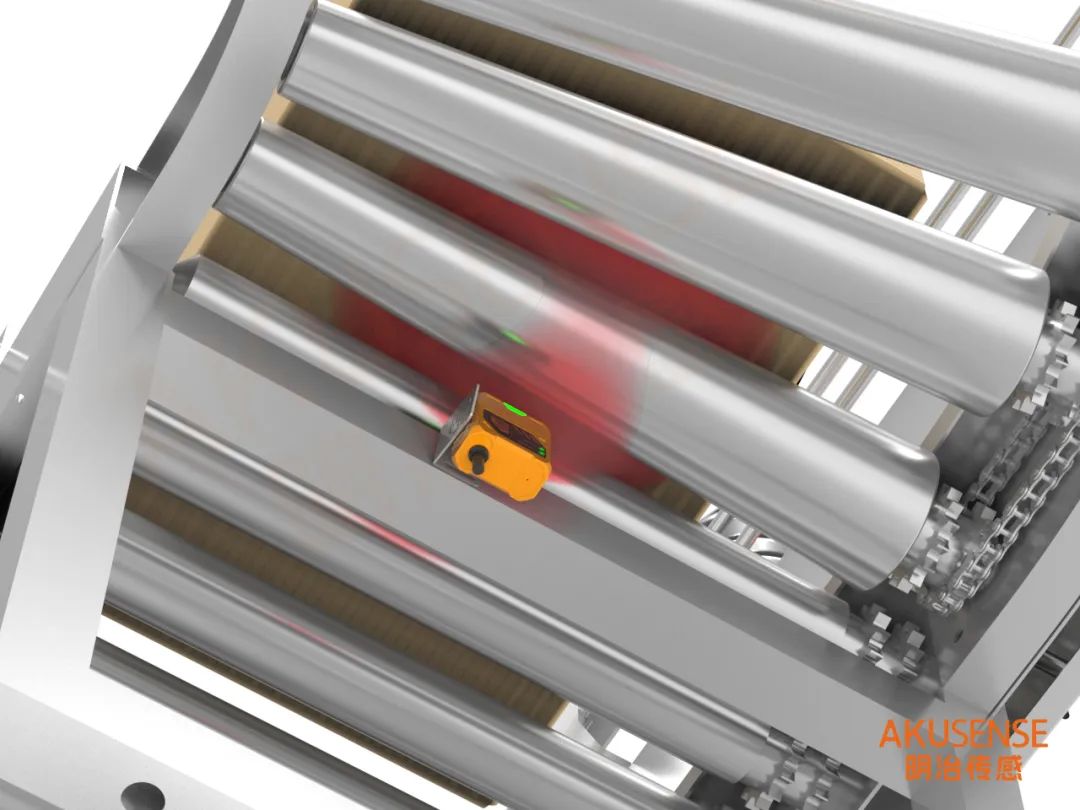

06 Check whether the cylinder position is in place

Magnetic sensor MR-C80

Application scenarios:

When an abnormal product is detected, the cylinder will push out the abnormal oil pot. A sensor needs to be installed to detect that the cylinder is in place and provide a switching signal for the expansion and contraction of the cylinder. The response is required to be fast, less than 1ms.

solution:

1. Use magnetic sensor MR-C80 and dual LED indicator light design to clearly identify motion conditions.

2. High positioning accuracy, reliable performance, the maximum switching frequency can reach 1000Hz

3. Full metal material, able to withstand harsh scenes such as vibration or heat

4. Micron-level response speed and high measurement sensitivity

07 Whether there is packing tape or not

Vision sensor VDS10-BQ0106-RP

Application scenarios:

The last work station for edible oil is packaging. The cartons are sealed with transparent tape. If there is no tape sealing, the product will fall. Visual inspection tools need to be installed here.

1. Stable monitoring of the presence of packaging tape is required.

2. It needs to be recognized while the conveyor is moving, and there are certain requirements for the recognition speed.

3. The sensor is required to output a switching signal after detecting an abnormality.

4. The sealing tape is transparent tape. After being illuminated by a red light source, the image will not be obvious.

solution:

1. Use the VDS10 series of visual sensors, which have extremely fine recognition capabilities. When the detection targets are very dense, the autoencoder learns the annotated structure information of the detection targets, and the recognition granularity is lower.

2. Visualization of the training process, one-click automatic parameter tuning, and can be used on the computer with just simple debugging

3. The maximum acquisition frame rate is 60FPS, which can easily handle the detection of moving objects.

+86 18188641602