Lithium battery cell tab cutting equipment

Lithium battery cell tab cutting equipment

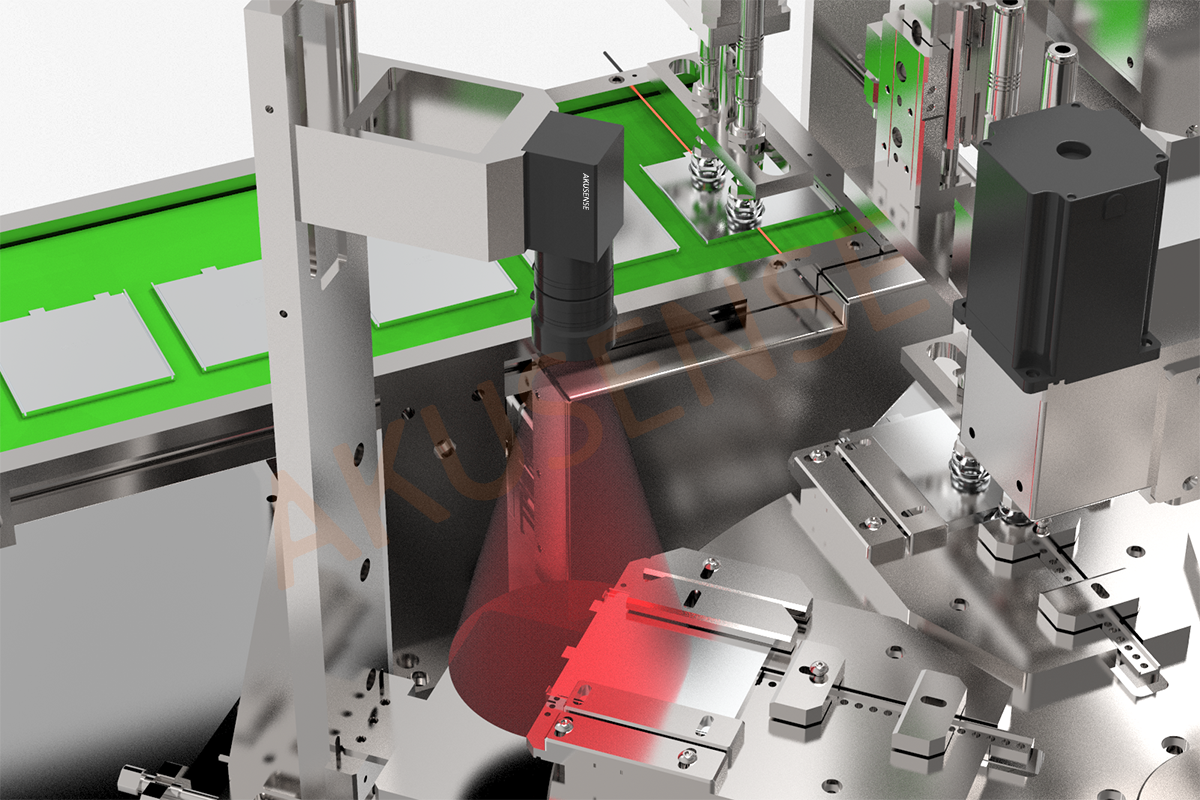

Application of sensors in lithium battery cell tab cutting equipmentIn the production process of lithium-ion batteries, cell tab cutting is an important process. During the cell manufacturing process, due to the size differences between different tabs, the front ends of the tabs are uneven after pre-welding of the multi-layer tab stacks. In order not to affect the subsequent cover welding and other processes, the front ends of the tabs are uneven. Parts need to be cut accurately to achieve good consistency, and lithium battery cell tab cutting equipment is produced to meet this need.

Application of sensors in lithium battery cell tab cutting equipment

Lithium battery cell tab cutting equipment is used for automatic loading and unloading of lithium battery cells, realizing battery cell OVC/IR detection, tab shaping and cutting, CCD visual detection of tab length and size, and automatic classification of defective and good products. In this issue, Xiao Ming will share the application solutions of sensors in each module of the lithium battery cell tab cutting equipment.

Loading robot module - TRN series proximity switch

The proximity switch is installed on the loading manipulator and is used to detect the presence of batteries in the pallet. When the batteries in the pallet are captured, a signal is sent to the manipulator to move the empty pallet to the pallet waiting station. It has the following advantages:

1. Use imported magnetic cores and cables to ensure the stability of the product;

2. Products of various sizes and specifications to meet the installation requirements of each workstation;

3. Positioning accuracy is as high as micron level.

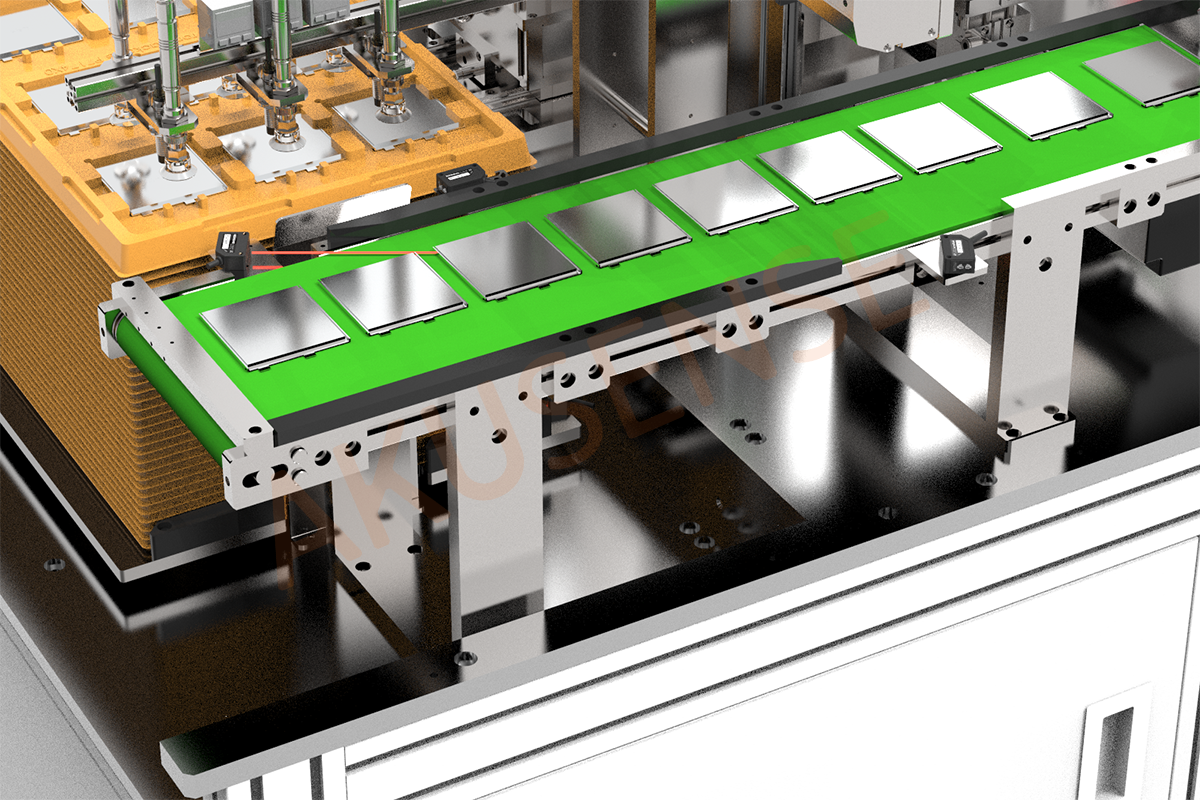

Loading station - PTE series through-beam photoelectric

Counter-beam photoelectric is installed on both sides of the loading station to detect whether the pallet is lifted in place and whether the pallet material is present. It has the following advantages:

1. Adopt advanced self-developed anti-interference algorithm with excellent stability;

2. Classic square appearance design, easy to install;

3. Multi-view indicator light display, knob to adjust sensitivity, easy debugging.

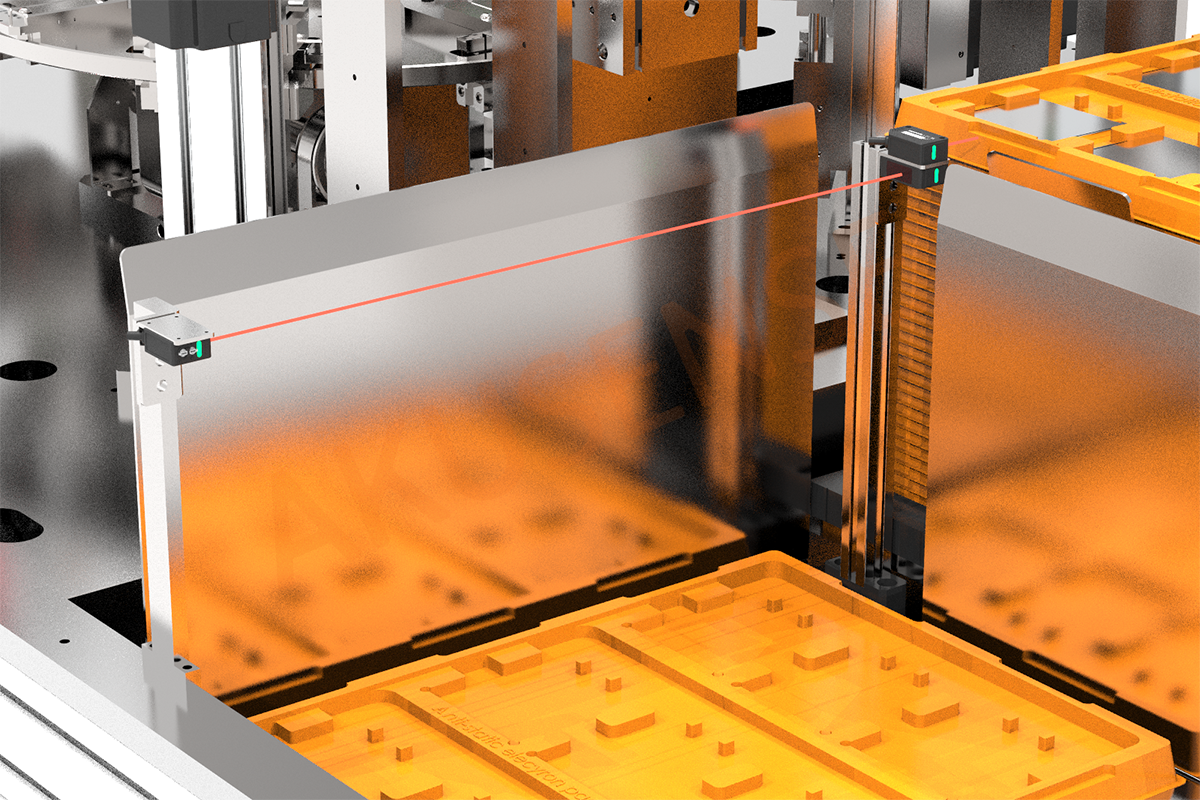

Loading belt line - ELE through-beam laser

Through-beam laser sensors are installed obliquely on both sides of the loading belt line to detect materials at corresponding positions on the belt to control the loading manipulator to grab and release materials. It has the following two advantages:

1. The ELE series through-beam laser has an ultra-long detection of 30m, and the light spot at 500mm is only 1mm;

2. Classic square appearance design, simple installation and convenient adjustment;

3. Import high-quality imported components to ensure performance stability.

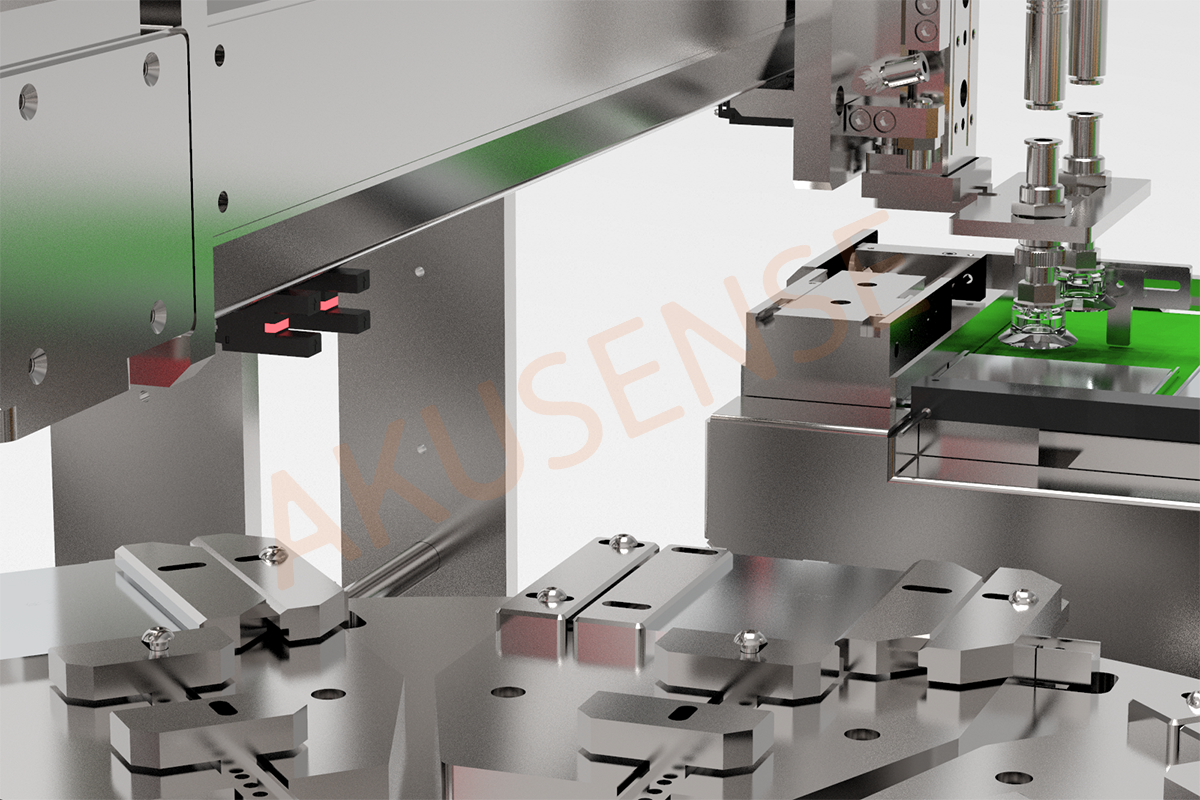

Loading and unloading, material transfer robot module-Trough Photoelectric

Installed at both ends of the module to control the origin and limit positions of the manipulator movement, it has the following advantages:

1. Chip integrated design ensures superior product consistency;

2. Positioning accuracy of 0.01mm;

3. Product design line protection, reverse connection protection, overload protection, etc.

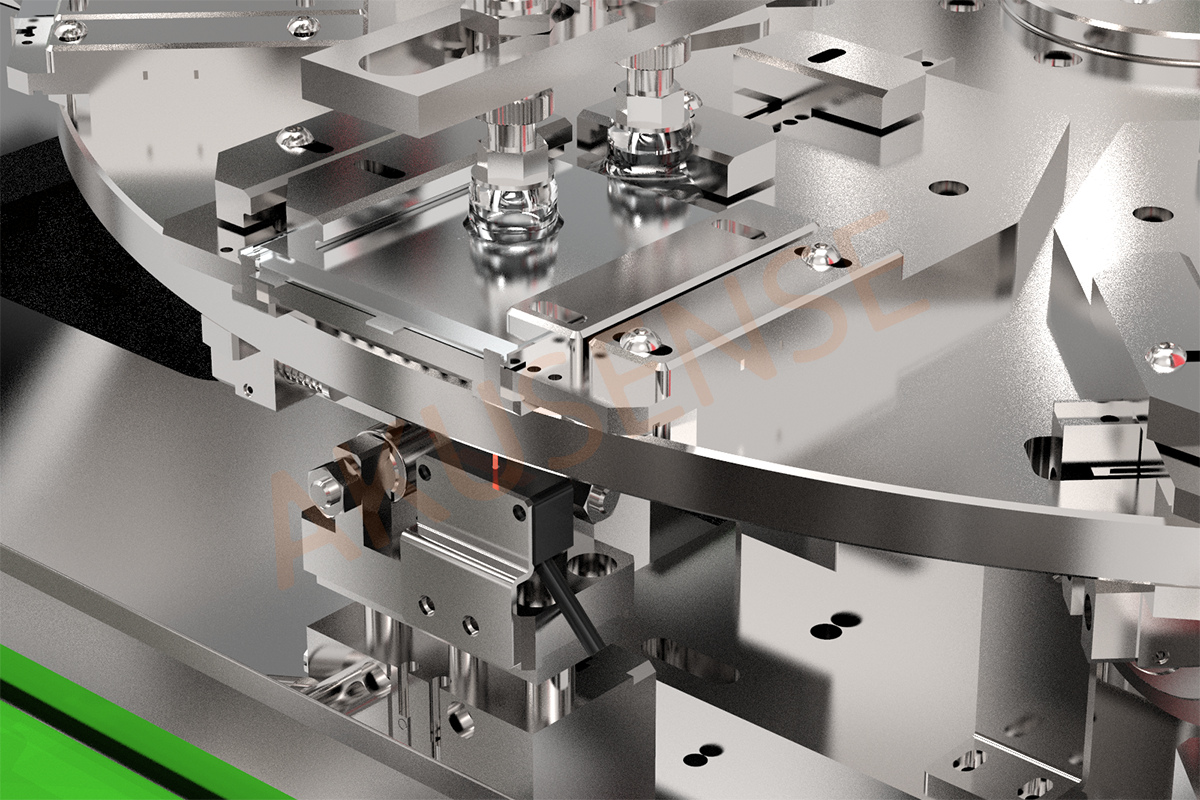

Cam Splitter Module - Background Suppression Photoelectric

The background suppression photoelectric is installed directly below the No. 1 station of the cam divider fixture to detect that the lithium battery cell is in place at this position, which has the following advantages:

1. Adopting the principle of laser triangulation, it is not afraid of the influence of the signal intensity reflected by the object being measured;

2. Modulate pulsed light to resist strong interference;

3. Red light/infrared light source configuration to meet various scene applications.

Cell tab CCD inspection station - visual inspection

Installed directly above the visual inspection station of the cam divider jig, it uses a backlight and camera to detect whether the pole lug cutting length is qualified. It has the following advantages:

1. Possess industry-leading machine vision algorithm capabilities;

2. Integrate the advantages of AI algorithms and traditional visual inspection to achieve new breakthroughs in visual inspection;

3. Highly integrated intelligent AI controller equipped with multiple visual detection algorithms.

Robot cylinder module-magnetic sensor

Installed on the loading and unloading manipulator and the cell positioning module to control the position of the module cylinder, it has the following advantages:

1. High positioning accuracy and reliable performance;

2. 5us high-speed response;

3. Rich product series, supporting matching of various complex industrial scenarios.

Cam blanking belt line - through-beam fiber optic

Through-beaming optical fibers are installed on both sides of the unloading belt line to detect battery core unloading, which has the following advantages:

1. High-speed response, up to 13us;

2. Anti-light interference control, automatic brightness compensation;

3. Rich optical fiber components to meet different requirements of industrial scenarios.

In the era of rapid development of the lithium battery industry, AKUSENSE has not only reached long-term cooperation with many leading companies, but is also actively seeking development and breakthroughs, constantly expanding its R&D team, upgrading production equipment, and improving the reliability, quality control, cost control and safety of product production. The expansion of production capacity provides a strong guarantee, builds high-quality sensors, and provides support for lithium battery intelligent manufacturing equipment companies to become industry leaders.

+86 18188641602