Efficient transmission of flower baskets

Efficient transmission of flower baskets

Indispensable for every photovoltaic smart factory - efficient transmission of flower basketsThe photovoltaic industry is one of my country's strategic emerging industries. Its development is of great significance for adjusting the energy structure, promoting the energy production and consumption revolution, and promoting the construction of ecological civilization. In recent years, under the dual role of national policy guidance and technological innovation drive, the photovoltaic industry has maintained a rapid growth trend, the industrial scale has continued to expand, and technology iterations have been constantly updated. It has now achieved a leading advantage in the global market.

Cost reduction, efficiency improvement and technological innovation are the themes of the development of the domestic photovoltaic industry. Photovoltaic companies are competing to create higher-efficiency battery products, and improving conversion efficiency will remain the main direction of the photovoltaic upstream and downstream industry chains. Meiji's R&D experts have actively proposed solutions suitable for various complex scenarios at the user's site in view of the uneven distribution of production capacity, high frequency of flower basket transmission, and frequent intersection of various processes in the photovoltaic industry production workshop, which has greatly improved the efficiency of the production process. Flexibility in equipment production. Help customers build more efficient smart factories and achieve unmanned production.

In this issue, we will share the use of sensors in flower basket transmission equipment before the silicon wafer is oxidized.

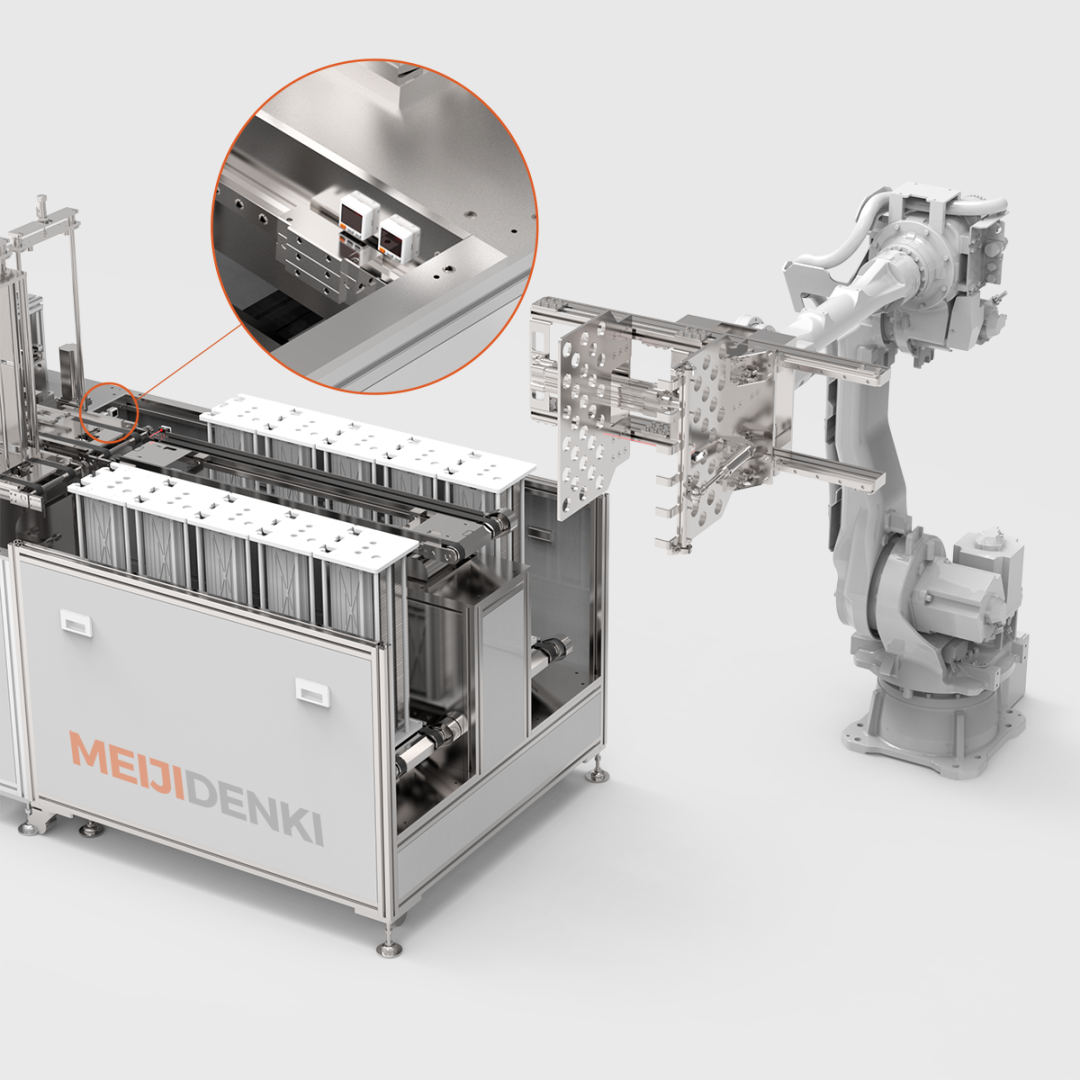

01 Flower basket transportation line

Photoelectric sensor PTE-R200N

Scenario requirements: Sensors are required to detect the position of the flower basket on the flower basket transportation line, so as to drive the machine to make the next action on the flower basket.

Solution: PVDF flower basket is an equipment used to carry monocrystalline silicon wafers and polycrystalline silicon wafers and complete the conversion, cleaning and drying process of silicon wafers. The bottom is hollow and some materials are reflective, so retro-reflective photoelectric PTE-R200N is selected. , the detection distance is adjustable, up to 200cm, easy to use. Standard 25.4mm mounting holes, switchable Lon and Don, simple and convenient debugging, multiple sizes of reflectors available.

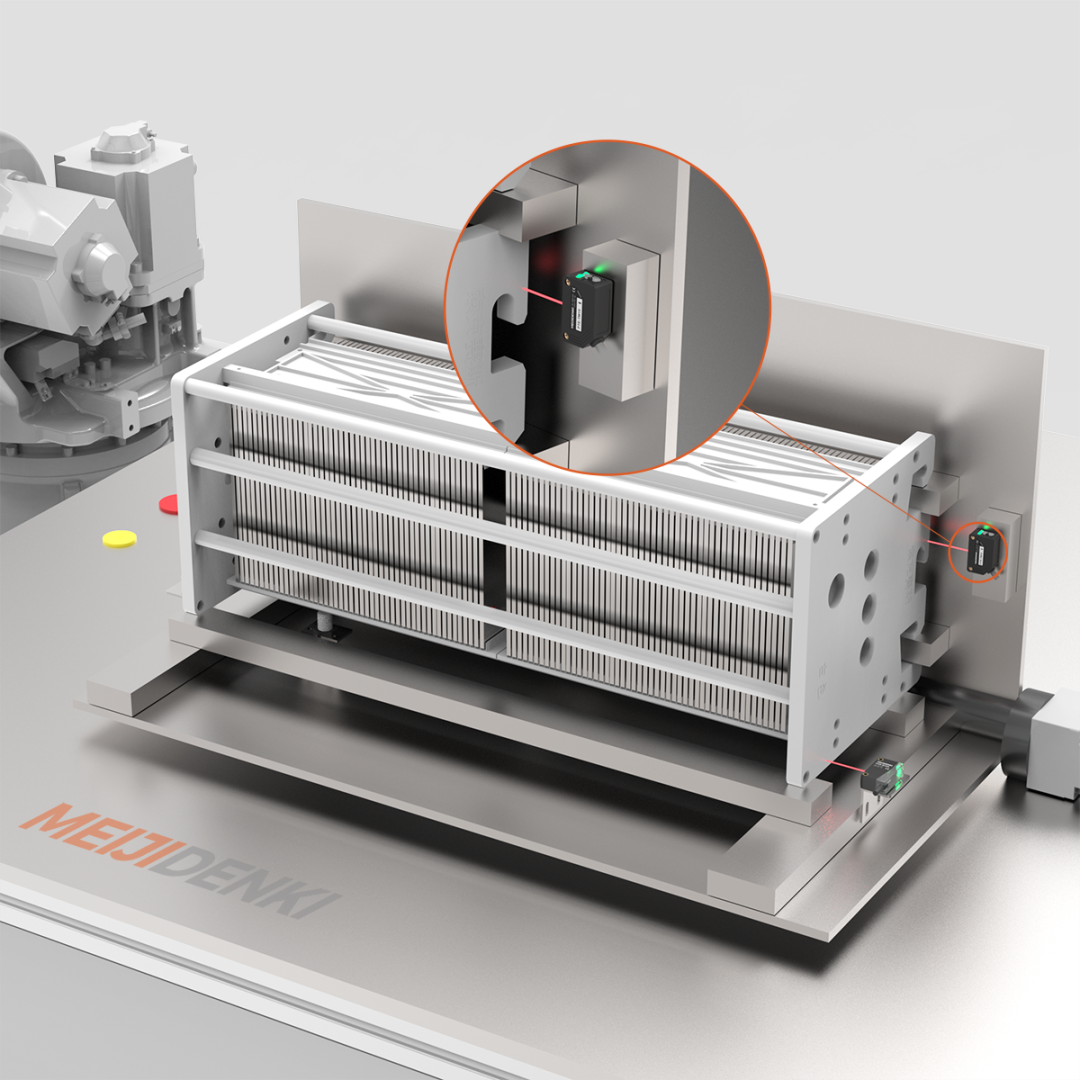

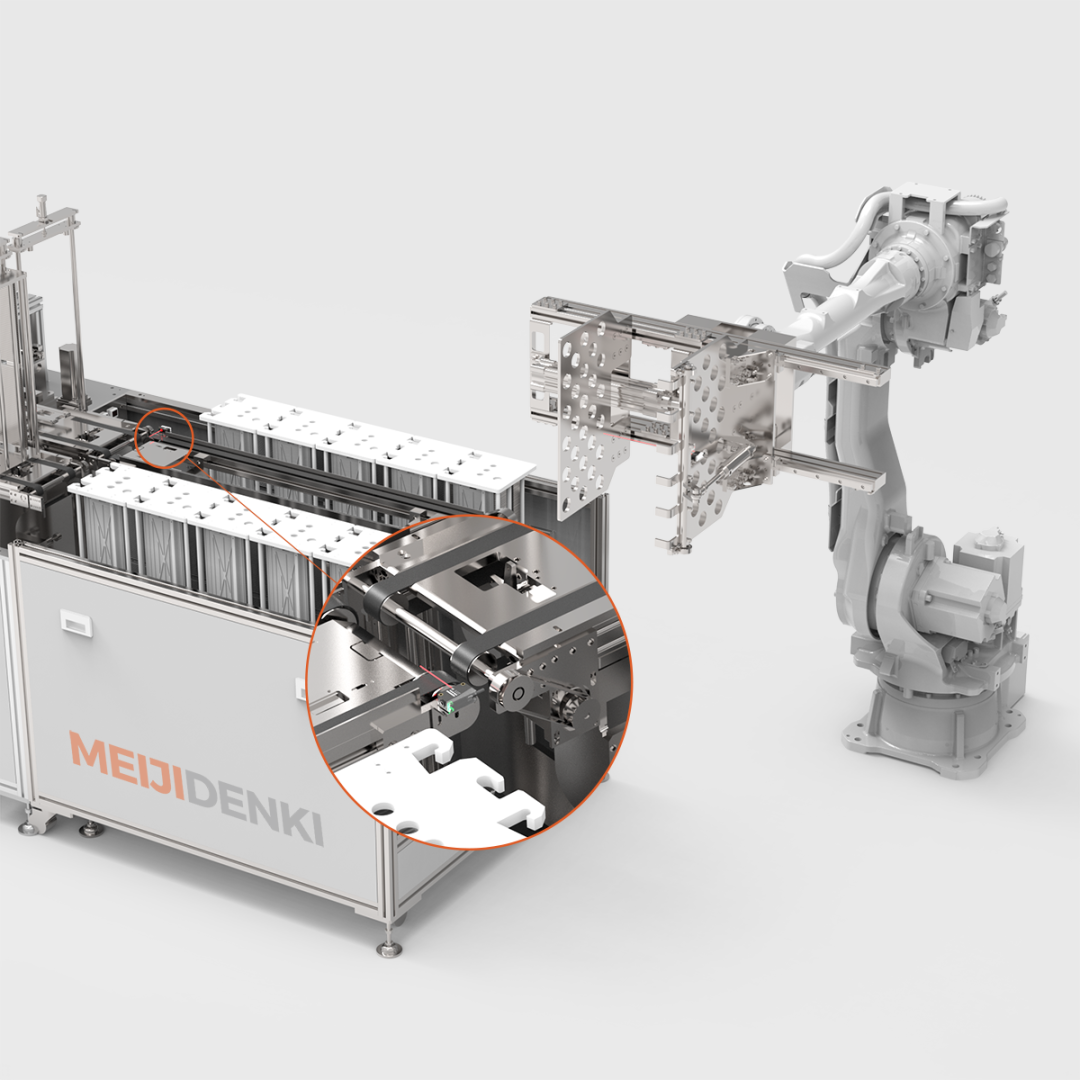

02 Hualan positioning detection

Photoelectric sensor PTE-TM10AN

Scenario requirements: A sensor needs to be used within a distance of 500mm to detect that the flower basket is in place

Solution: You can choose the PTE-TM10 series of through-beam photoelectrics with adjustable detection distance. The detection distance can be up to 10m, which meets the needs of medium and long-distance applications on site (500mm). The standard 25.4mm mounting hole, Lon and Don can be switched, and debugging is simple and convenient.

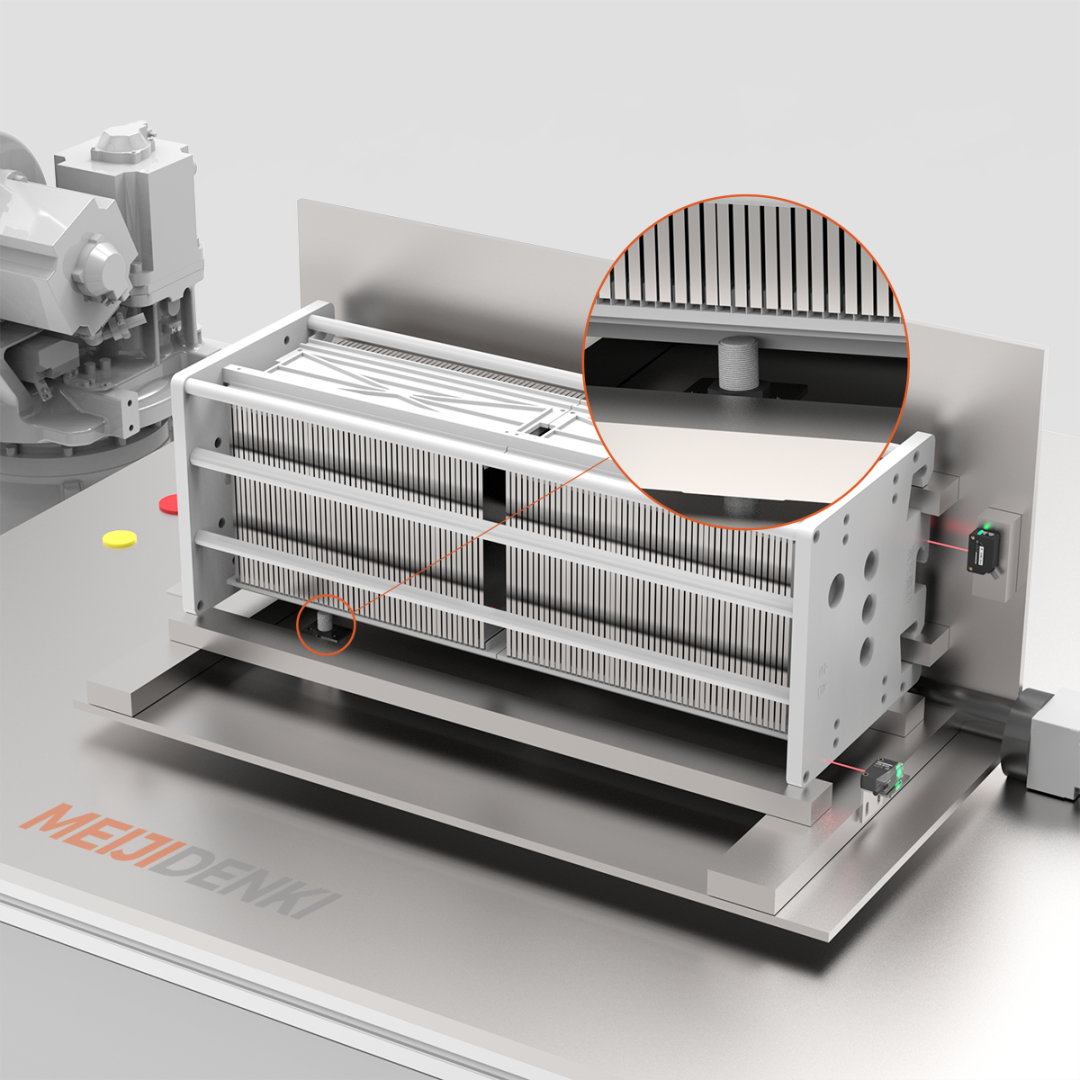

03 Front and back positioning detection of flower basket rotated 90°

Background suppression type photoelectric ESB-BS15N

Scenario requirements: After the flower basket rotates 90°, it is necessary to detect and confirm whether it has completed the rotation; the sensor needs to pass through a 20mm hole for detection, and the light spot is required to be small and to be able to shield items outside the detection target distance.

Solution: Use the small spot photoelectric ESB-BS15N with background suppression function, which is not affected by the color and material of various silicon wafers, and the spot is only 2mm at 150mm; it has the ability to identify step differences and can perform background shielding on silicon wafers at 50mm. , only recognizes the flower basket positioning hole at 30mm, and the red light has strong anti-interference ability. Even if it is illuminated by the red light sensor at the opposite station, the stability of the detection will not be affected at all.

04 Silicon wafer status detection

Photoelectric sensor ESB-B30N

Scenario requirements: Detect the status of silicon wafers to prevent damaged or large defective wafers from flowing into the next process.

Solution: Install the background suppression photoelectric sensor ESB-B30N, which is not affected by color, at an angle of 45°, 100mm away from the flower basket, and provide timely feedback when the chip is not detected. It has a strong ability to resist LED light interference, even if it is illuminated by the light emitted by the LED lighting above, it will not be affected at all.

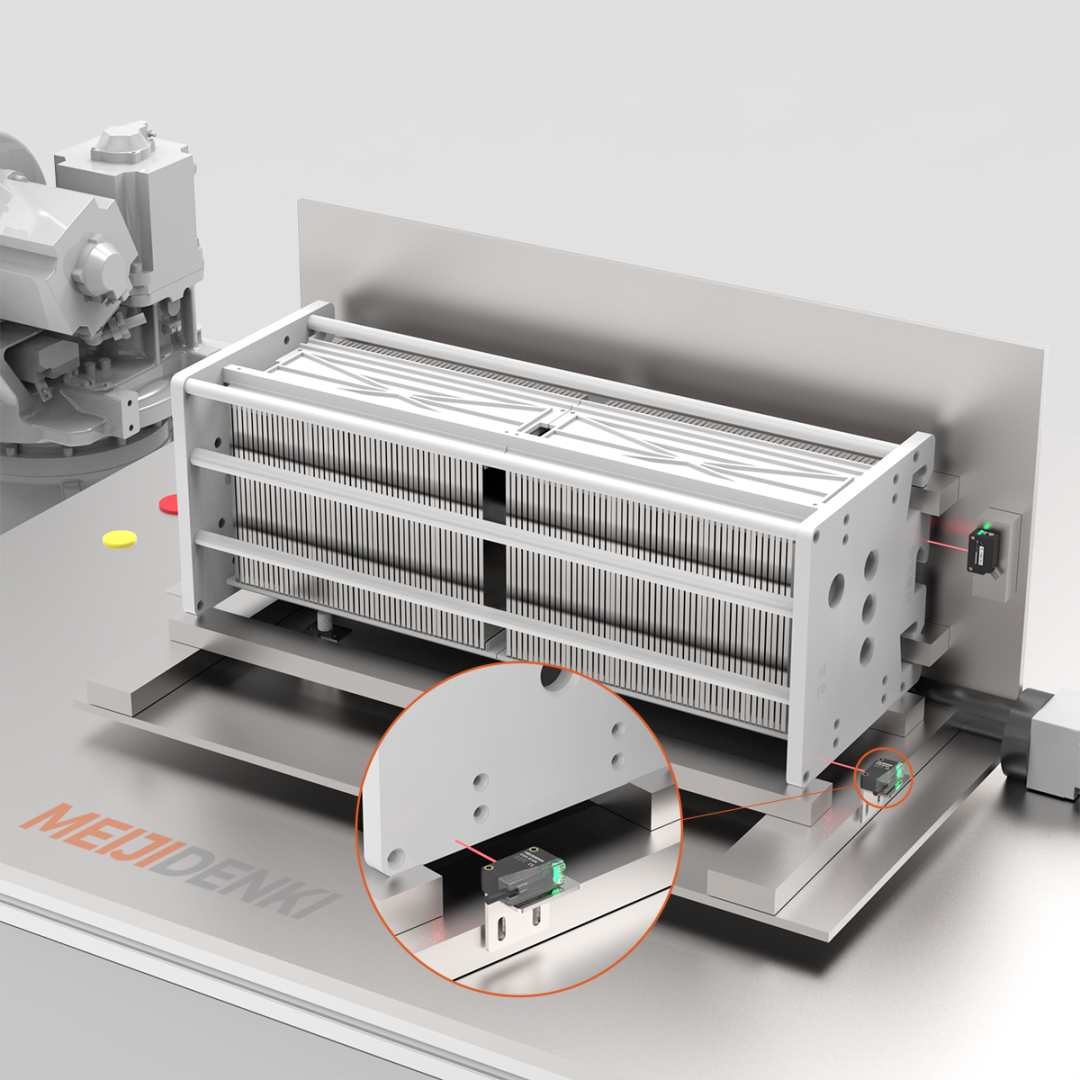

05 Flower basket positioning detection

Capacitive proximity sensor CKF12-03NO

Scenario requirements: Positioning the flower basket column during transmission, the detection distance is small, the detection repeatability is within 0.1mm, and the detection distance is required to be 2mm.

Solution: The flower basket is non-metallic and has a short detection distance. It can be detected with the CKF12-03NO capacitive proximity sensor. It has high repeatability and is installed with M12 threads to save space. The detection distance is adjustable from 1-3mm and is easy to use.

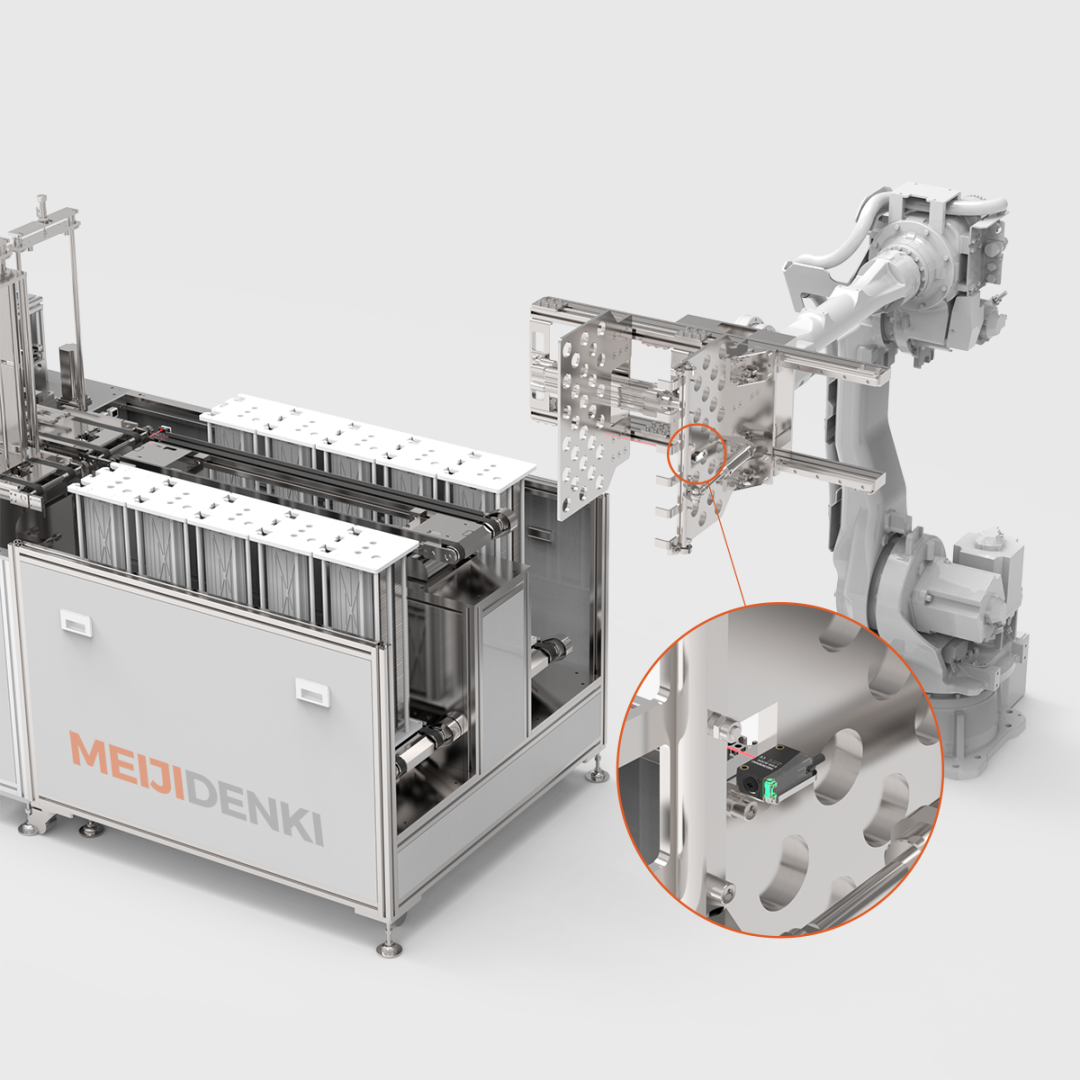

06 Robot material grabbing and positioning

Background suppression type photoelectric ESB-BS15N

Scenario requirements: At this station, sensors are needed to position the flower basket, thereby driving the manipulator to grab the flower basket. Flower baskets come in various colors and materials, including black, milky white, light brown, dark blue, etc. Therefore, it is necessary to choose a sensor that is not affected by color. The ambient light in this workstation is strong, so more consideration must be given to the anti-interference performance of the sensor.

Solution: Use the laser sensor ELE-BS15N, which is not affected by color and has strong anti-interference ability from stray light. It is almost not affected by reflection interference from the floor surface under the robot, the metal surface of the equipment, the glass surface of the door bed, etc.; it is resistant to interference from LED lights. It has strong capabilities. Even if the light emitted by the LED lighting is installed above the equipment, the ELE-BS15N sensor will not be affected at all and can very well complete the task of grabbing and positioning materials by the robot.

07 Conveyor section flower basket positioning detection

Background suppression type photoelectric ESB-BS15N

Scenario requirements: During the transmission process of the flower basket, sensors are required to position it. Various flower baskets come in different colors and materials, including black, milky white, light brown, dark blue, etc. Most of the materials are PVDF/PTFE and are reflective; the installation station is positioned at the bottom of the flower basket, and some are hollowed out.

Solution: Use the sensor ESB-BS15N with background suppression function. The light spot is small, only 2mm at 150mm. It has a high-precision detection of 70mm and the positioning repeatability is less than 0.5mm. It has strong anti-interference ability of ambient light and almost no trace of the floor under the sensor. Surface, metal surface of the equipment, glass surface of the door bed and other reflective interference, the response speed is as fast as 1ms; it can achieve accurate positioning of the transmission effect.

08 Cylinder transmission air pressure measurement

Pressure sensor MQ-01D

Scenario requirements: Real-time detection of air pressure value during cylinder transmission, measuring range 100-100KPA

Solution: Real-time monitoring of air pressure value, linear accuracy requirement ±0.1%F.S, sampling frequency 2.5ms

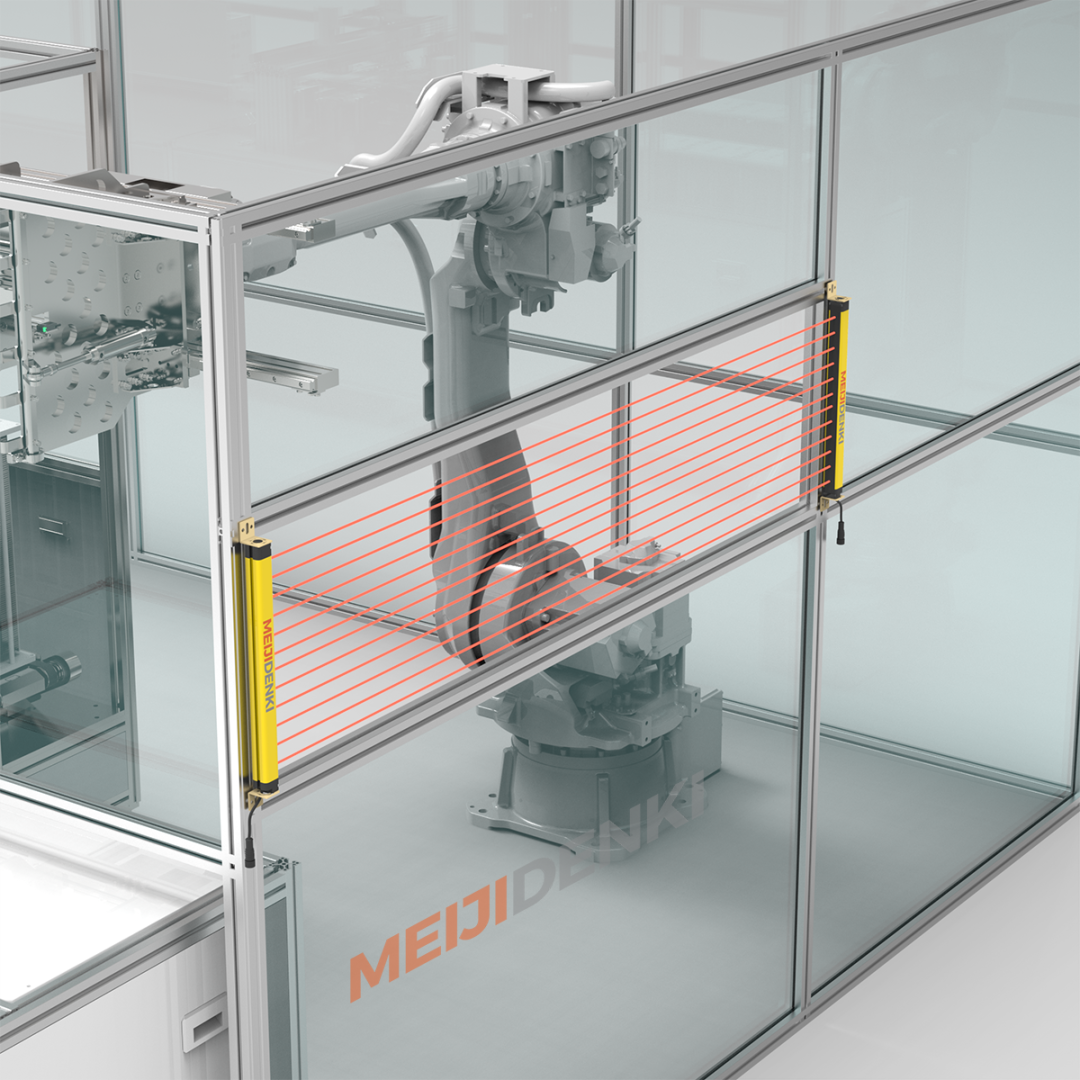

09 Personnel safety protection

Safety light curtain BSL40-T1006NC

Scenario requirements: During mechanical operation, in order to prevent people from accidentally entering and causing injuries, safety protection devices need to be designed on the equipment.

Solution: Choose the BSL series safety light curtain, which is safe and stable, has a response speed of less than 20ms, has good light interference resistance, and is completely free from laser pulse interference emitted by the lidar on the AGV trolley on site.

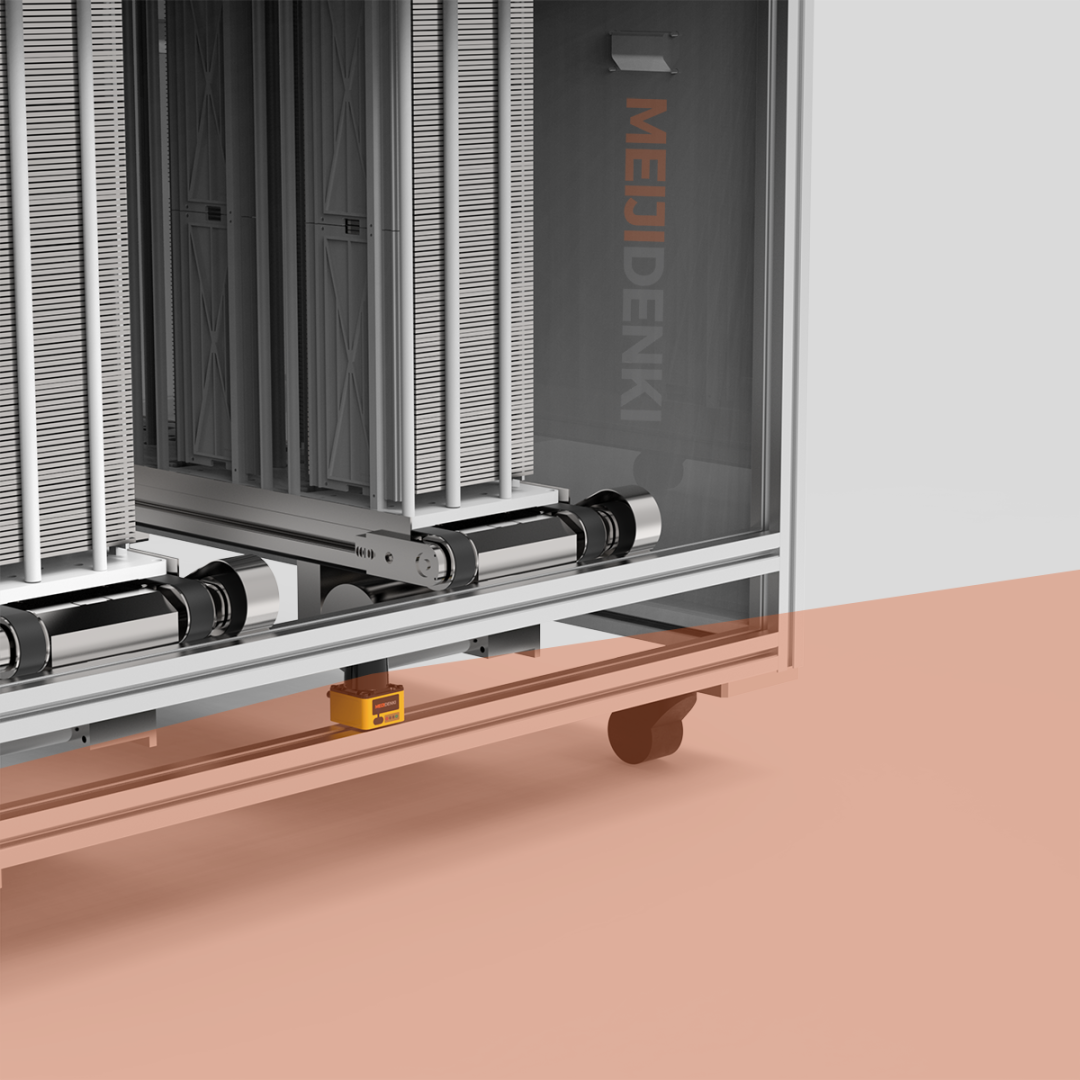

10 AGV vehicle obstacle avoidance

LiDAR AS-33C

Scenario requirements: After the AGV receives the task, it calculates through the internal program to find the mobile shelf to accept the goods, and transports the mobile shelf filled with flower baskets to the next process for loading. During this process, the AGV car needs to have obstacle avoidance to avoid the goods. Collisions during transportation cause damage to fragile silicon wafers.

Solution: Choose the AS-33C series laser obstacle avoidance radar and install it in the AGV car to perform a wide range of 270° area detection at a distance of 10m around. 3 obstacle avoidance areas are set to meet the three states of vehicle running, deceleration and stop. Accuracy 2cm.

+86 18188641602