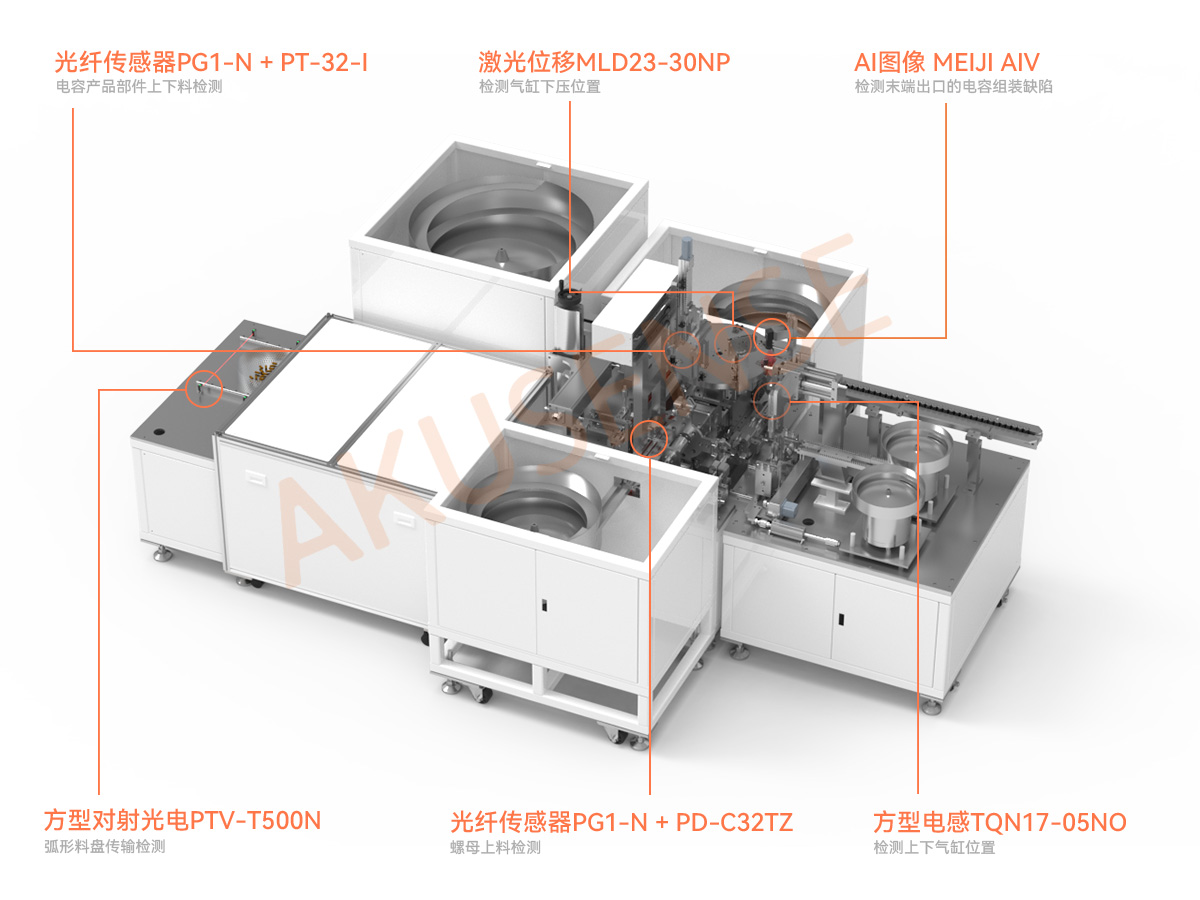

Capacitor automatic assembly machine

Capacitor automatic assembly machine

In capacitor automatic assembly equipment, these sensors help you to get twice the result with half the effortAs one of the three basic passive electronic components (resistors, capacitors and inductors), capacitors occupy an important position in the electronic component industry. They are mainly used for tuning, filtering, coupling, bypassing and energy conversion in circuits. They are one of the essential components in electronic circuits, accounting for about 56% of the global passive electronic component market.

Among them, high-end capacitors are an important part of the current capacitor industry, mainly used in consumer electronics, automotive industry, aerospace, industrial applications, lighting and other industries. Due to the huge downstream market and the rapid development of the consumer electronics industry and electric vehicle field, the development of the high-end capacitor industry has brought continuous driving force. Many leading manufacturers have expanded production and optimized processes to cope with the growth in demand and high-quality requirements.

In this issue, I will share with you how Meiji helps the capacitor automatic assembly machine to accurately sense and operate efficiently~

01 Capacitor cover loading and unloading detection

Fiber optic sensor amplifier PG1-N & Component PT-32-I

Application scenario:

The capacitor product vibration plate passes through the guide rail and is transferred to this station. The sensor is used to detect the presence of the capacitor cover, and then the correct product is moved to the next station through the loading and unloading cylinder

Detection requirements:

1. Because the cover size is small, about 10mm, it is required to be able to detect tiny objects

2. When multiple tiny objects pass quickly, it is required to clearly distinguish each object

3. The material transmission speed of the production line is about 1 second 5pcs. The response speed is required to be within 100ms

Solution:

1. Use optical fiber sensor detection, the diameter is about 3mm, the light spot is small at a distance of about 10mm, and it can be stable Detect tiny objects

2. The PG1-N amplifier can accurately adjust parameters through the digital display to detect the object under movement

3. PG1-N has a microsecond response speed and can perfectly match various high-speed detection scenarios

4. PG1-N has 4 gears of adjustment, including high-speed, standard, high-precision, and long-distance modes, which can adapt to various detection needs

5. L/D output can be switched freely, which is easy to use

6. 4 channels are anti-light interference, and still perform well in side-by-side installation environments

7. PT-32-I is a convex tube diffuse reflection optical fiber with small size and easy installation. It is suitable for detecting tiny objects and has excellent anti-electromagnetic interference effect

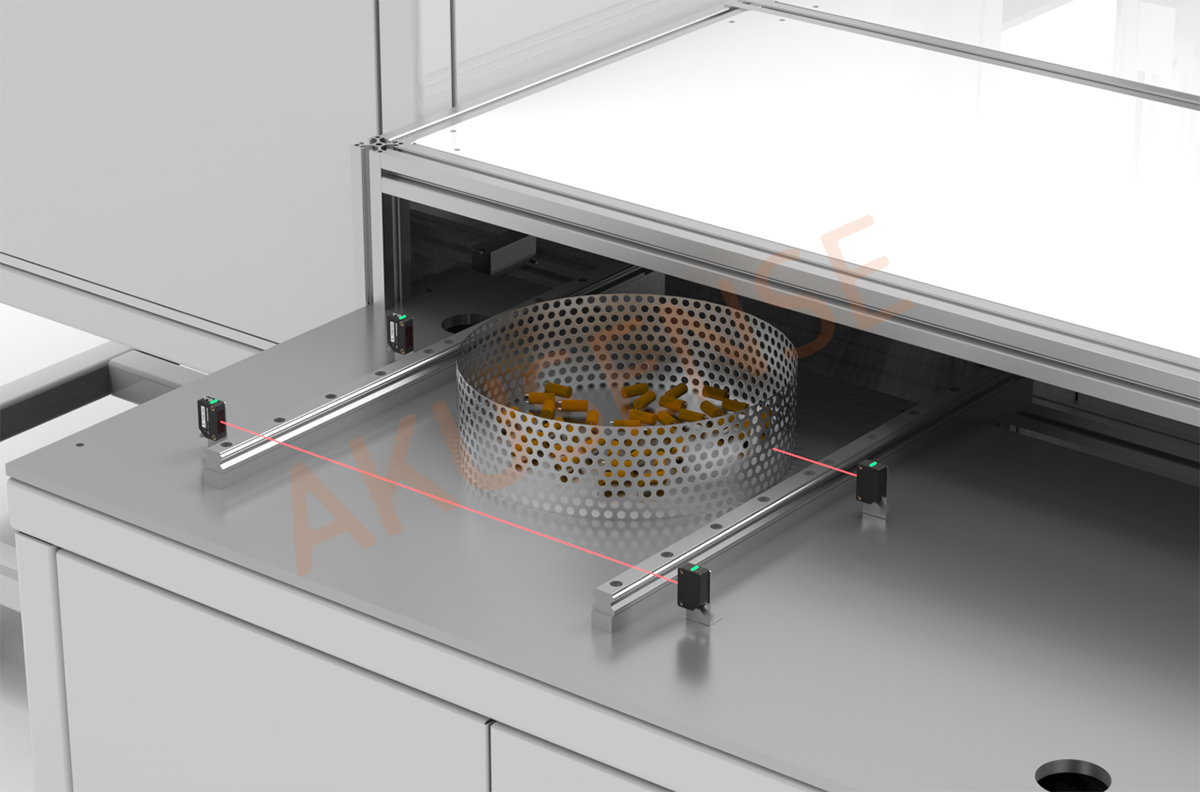

02 Arc tray transmission detection

Photoelectric sensor PTV-T500N

Application scenario:

When the arc-shaped material tray enters the specified position, the sensor detects whether the material tray is in place, and when the material tray is in place, the next station action is triggered

Detection requirements:

1. The material tray is arc-shaped, and the sensor needs to be selected without being affected by the shape of the object being measured

2. There are multiple small holes on the object being measured, and the light spot will leak light through the holes and cause misjudgment

3. There are multiple small holes with a diameter of about 2-3mm on the material tray. When the sensor light spot is irradiated, penetration will occur, and the detection difficulty is relatively high.

4. There is lighting above the station, which is easy to cause light interference to the sensor

5. There is a stepper motor next to the station, which will generate an electromagnetic field during work and interfere with the sensor

Selection advantages:

1. The sensor is not affected by the color/surface of the object being measured by adopting the principle of photoelectric reflection Impact of state/background interference

2. Through close-range photoelectric transmission, the sensitivity is adjusted to achieve accurate detection, solving the problem of detecting small holes on the object being tested

3. The detection distance is 5 meters, and the sensitivity is adjustable, which is fully satisfied in this scenario, and it is easy to install and debug

4. The product uses imported light sources, and there is still no obvious light decay after a long period of work, which ensures long-term stable detection of the product

5. This sensor has strong anti-light interference ability, sunlight can reach 10000lux, incandescent lamp can reach 3000lux, and it can still detect stably when the equipment is running at night with lighting interference

6. The product has been precisely designed and has strong anti-electromagnetic interference ability, and can still operate stably in a certain alternating electromagnetic field

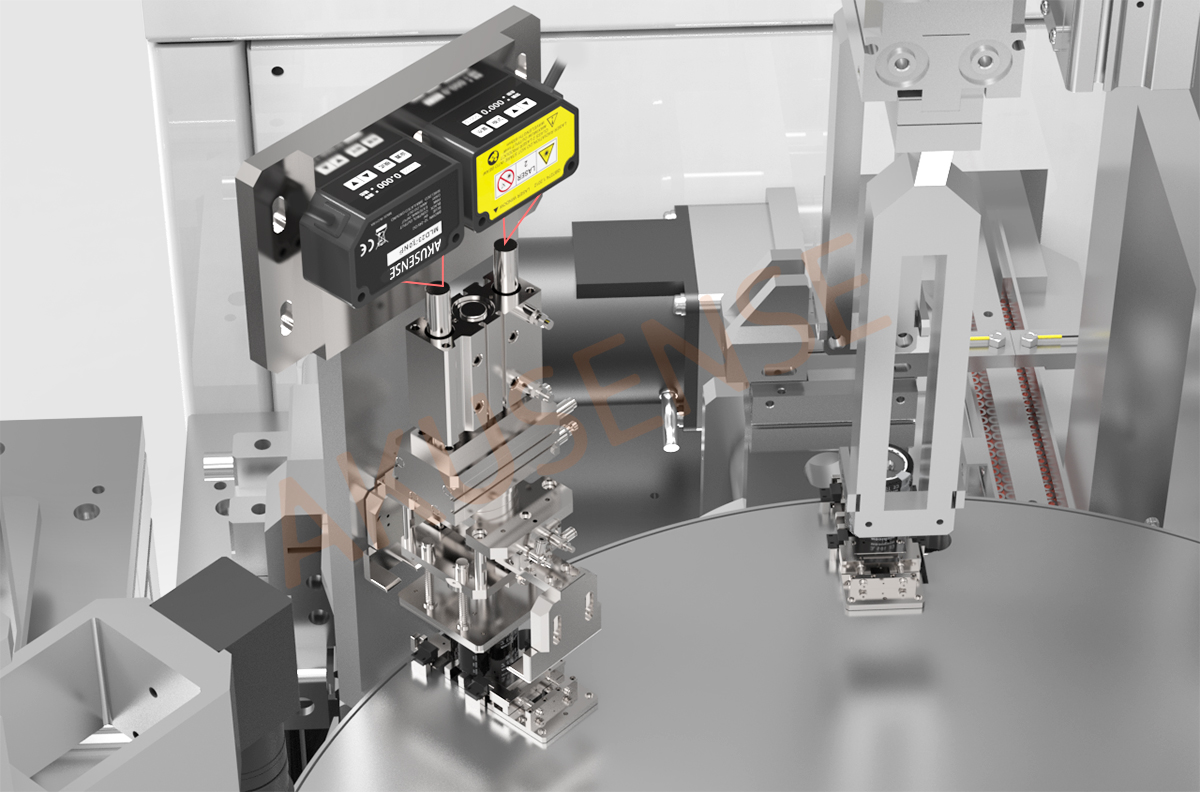

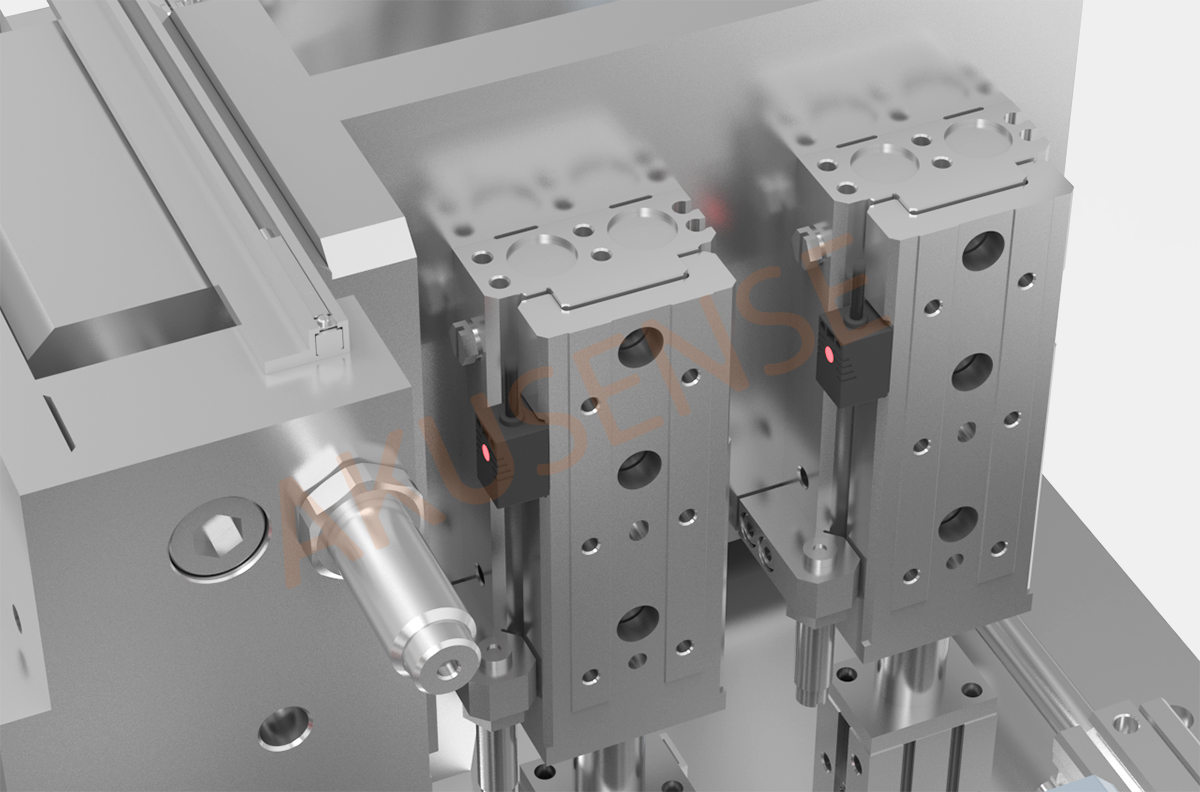

03 Cylinder down position detection

Laser displacement sensor MLD23-30NP

Application scenario:

When the cylinder is pressed down to fasten the product, the laser displacement is used to detect the cylinder's pressing position, and a signal is output to determine whether it is pressed in place

Detection requirements:

1. The detection repeatability accuracy is required to be within 50 μm

2. The cylinder base size is small, about 15 mm, and a sensor with a small spot is required

3. The detection accuracy is high, and it requires compatible switch and analog outputs

4. The detection position is visualized, and real-time process monitoring is required

Solution:

1. Use laser displacement sensor, designed based on the triangulation optical detection principle, which can To accurately and stably detect whether the cylinder is in place

2. Micron-level display resolution, humanized panel design, easy to use

3. 3-speed response time mode can be adjusted, the fastest can reach 1.5ms

4. Repeatability accuracy can reach up to 10 microns

5. The spot size is about Φ0.05mm, which can stably detect tiny objects

6. Imported laser light source, light source level Class2 can effectively protect human eyes and other tissues (except for intentional direct viewing of laser)

7. Designed according to the usage habits of domestic users, Chinese display screen and software improve the convenience of operation and debugging

04 Cylinder up and down position

Proximity sensor TQN17-08NO

Application scenario:

When the upper process of the material is completed, the cylinder will move up and down, drive the upper and lower grippers to pick up the material, and transport it to the next station. The sensor detects whether the cylinder position has changed

Detection requirements:

1. Repeatability is less than 0.5mm

2. There is a stepper motor next to the station, which will generate an electromagnetic field during operation, causing certain interference to the sensor, and requires good anti-interference ability

3. The response rate must be less than 1ms

Solution:

1. Use non-embedded inductive proximity sensor TQN17-08NO, waist-shaped mounting hole, simple installation

2. The detection distance is 8mm, and the cylinder position can be detected at a distance

3. The repeatability is 1%F.S, about 0.08mm, which can accurately avoid the loss of material scrapped due to loose cylinder position and incorrect up and down movements

4. The response frequency is 1KHz, which can meet high-speed detection scenarios

5. The product has strong anti-electromagnetic interference characteristics and still runs stably during motor start and stop

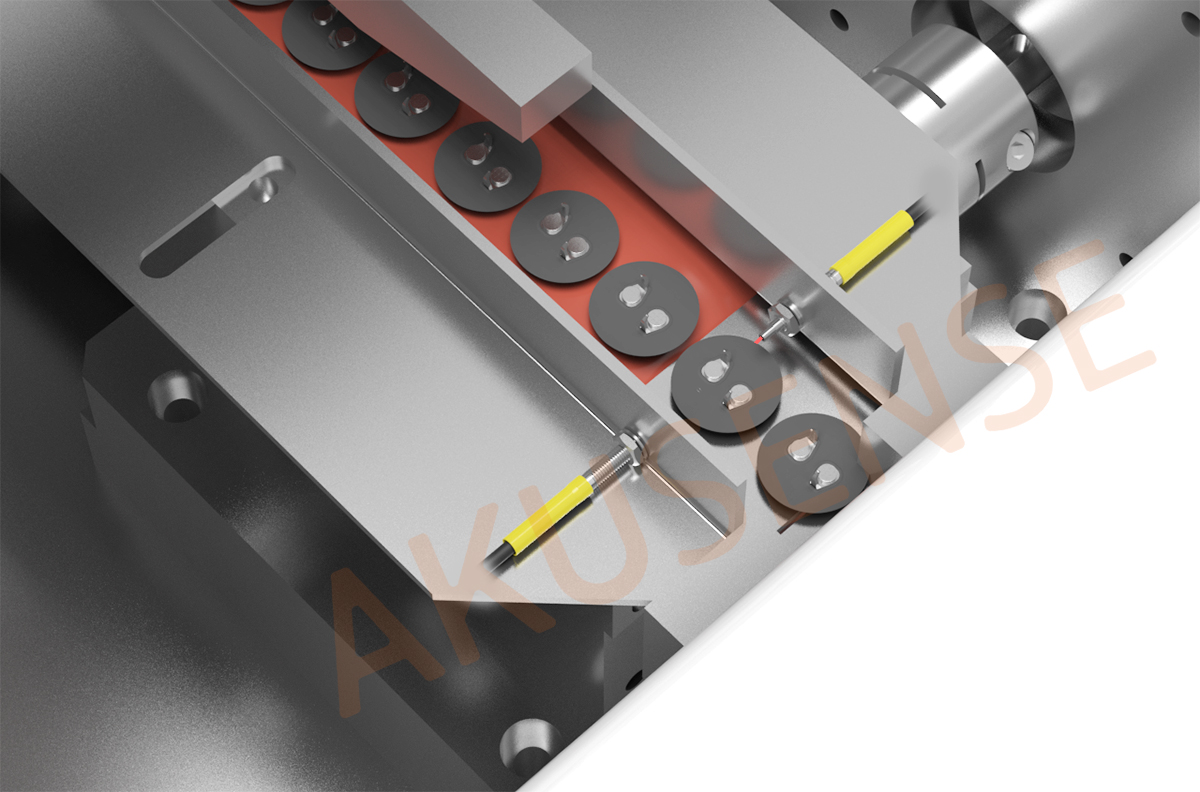

05 Nut feeding detection

Fiber optic sensor amplifier PG1-N & component PD-C32TZ

Application scenario:

The product passes through the vibration plate guide rail and is transferred to this station. The sensor is used to detect whether the nut is in place to trigger the signal to the host computer for counting

Detection requirements:

1. Because the nut size is small, about 2-3mm, it is required to be able to detect tiny objects

2. When multiple nuts pass quickly, it is required to clearly distinguish each object

3. The surface of the nut is a high-gloss surface and is not required to be disturbed by reflected light

3. The production line speed material transmission speed is about 1 second 30pcs. The response speed is required to be within 30ms

Solution:

1. PD-C32TZ is a direct Angled fiber optic cable saves installation space

2. The fiber core type is coaxial wraparound, which has higher detection accuracy and stronger stability than ordinary fiber optic cable

3. The fiber optic cable is made of imported fiber optic cable core, with a bending radius of R5, and can be easily installed in the gap or narrow space of the machine

4. The fiber diameter is about 3mm, and the light spot is small at a detection distance of about 10mm, which can stably detect smiling objects

5. The PG1-N amplifier can accurately adjust the parameters through the digital display screen, and can detect the object under movement

6. The PG1-N has a microsecond response speed, which can perfectly match various high-speed detection scenarios

06 Defect Detection

AI Image Recognition Meiji AIV

Application Scenario:

After the capacitor is assembled, defect detection is required to ensure product yield

Detection requirements:

1. The field of view requires about 50-100mm to achieve high-precision detection

2. The detection accuracy requires about 0.2mm

3. The working distance requires less than 300mm

4. The detection cycle requires 0.5s or less

5. The detection function requires output IO and serial communication, and generates production record reports, and requires simple operation

Solution:

1. Adopt Meiji AIV visual inspection solution, customized according to customer needs, integrating the advantages of AI algorithm and traditional visual inspection, super model parallel and image processing capabilities, achieving detection accuracy of 0.15; 0.05mm, effectively improving product yield

2. The working distance is 200mm, and the equipment is small and occupies little space

3. Visualization of test results, support one-click export, convenient data sharing and management

+86 18188641602