Automatic labeling machine

Automatic labeling machine

These sensors help the automatic labeling machine’s sensing system go faster! allow! stable!In the packaging industry, with the development of automation technology, fully automatic labeling machines have attracted more and more attention. It has a high degree of automation and can achieve continuous labeling. It is a modern mechatronics product with excellent and reliable work. Performance, including the advantages of greatly reducing manpower input, clean and hygienic packaging, beautiful and strong labeling, etc.

The automatic labeling machine uses labeling equipment to automatically paste labels on the objects to be labeled. It is mainly composed of transmission components, label printing equipment, connecting components, brackets, shells and other components. It can be used for labeling work in industrial production, such as canned food. Labels, industrial product labels, artwork labels, etc., the equipment can improve production efficiency and promote the upgrading of product packaging. In the automatic labeling machine, today I will share with you the application of sensors in the automatic labeling machine.

01 Loading turntable in place detection

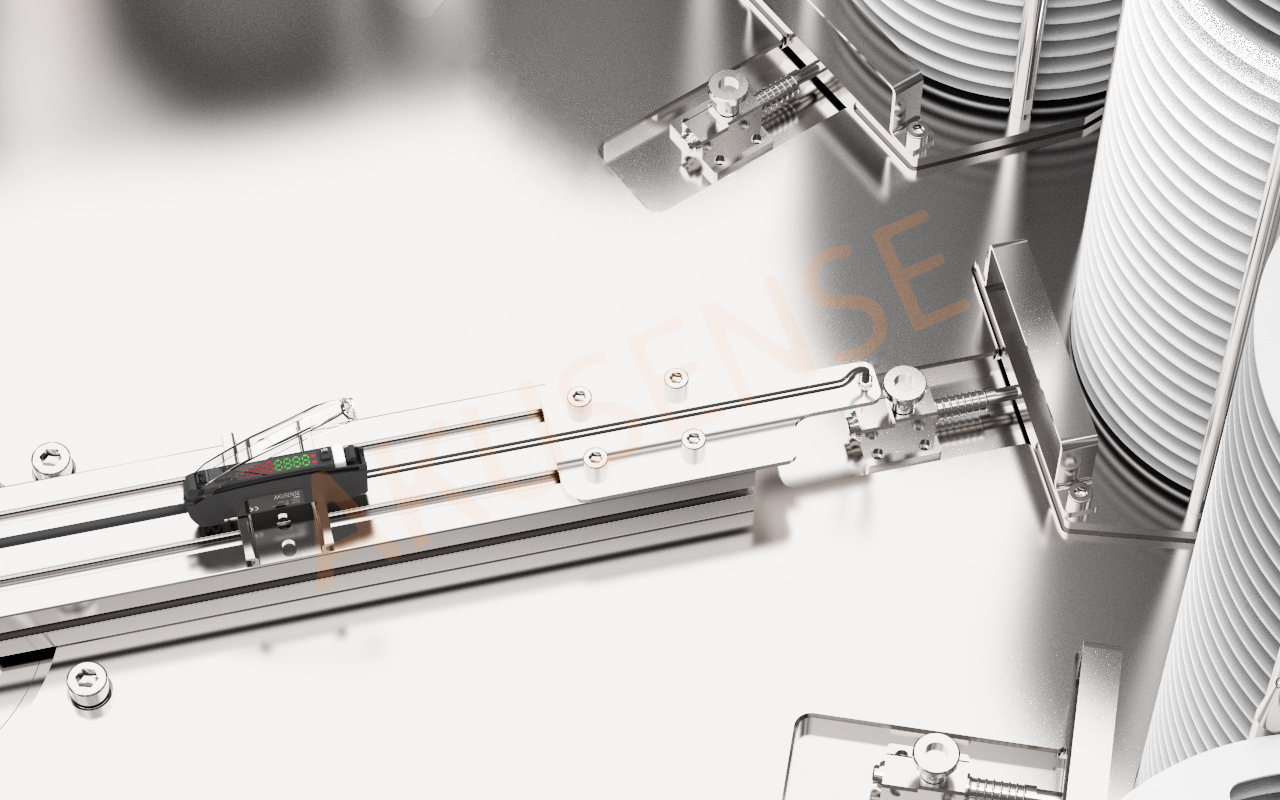

The speed of the loading carousel often needs to be adjusted according to the production situation. Here, a PE1 optical fiber amplifier + PD-32 cylindrical fiber unit with five adjustable speeds (100us, 400us, 800us, 1600us, 3200us) can be used, which is installed on the loading carousel. At the middle structure, the position of the loading station on the rotating disk is detected.

02 Accurate positioning of materials

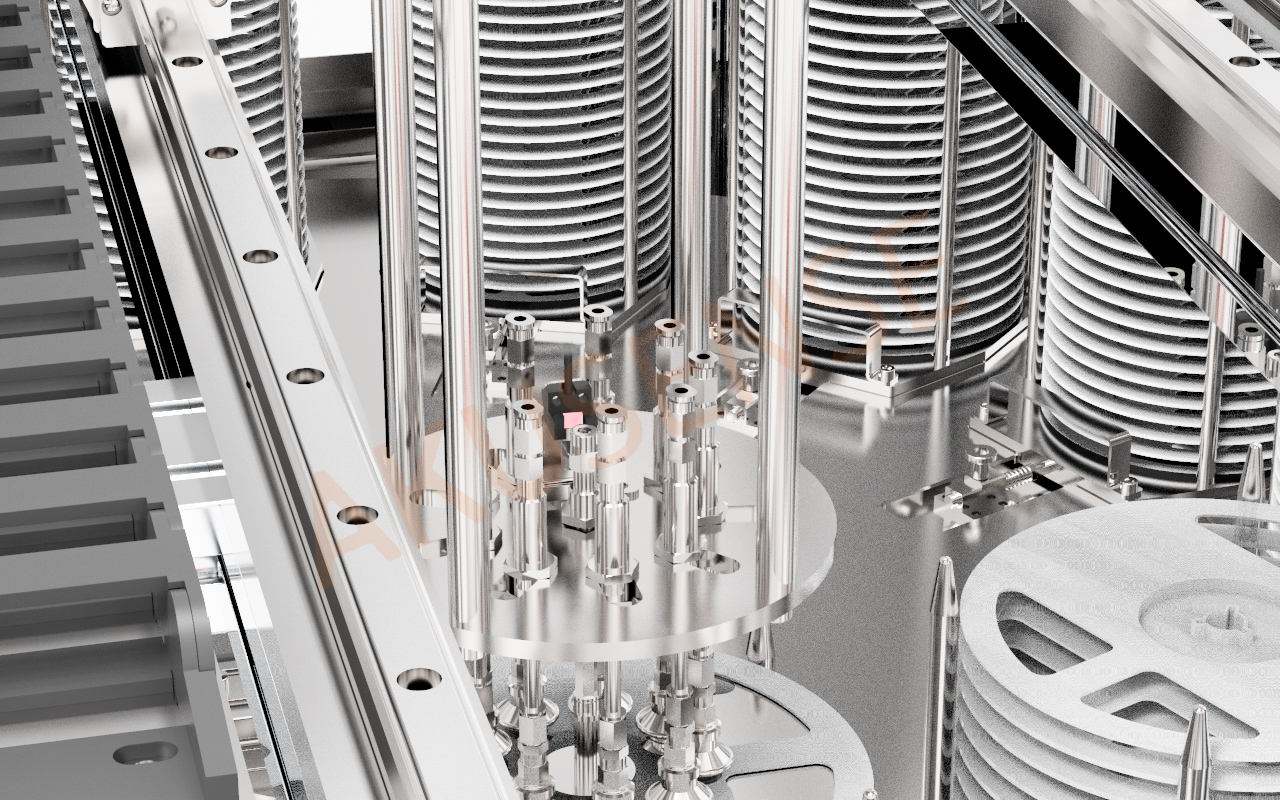

At the turntable loading station, sensors need to be used to control the manipulator to grab and load products. For some relatively small products, higher positioning accuracy is required, and the equipment installation space is also very limited. Using positioning accuracy can The tiny groove-shaped photoelectric SL-205 of 0.01mm precisely controls the position of the manipulator movement, ensuring the accuracy of the manipulator's grasping.

03 Robot grasping and positioning

The labeling station needs to use sensors to precisely position the movement of the manipulator, which serves as the joints of the mechanism to ensure that the movement of the mechanism will not be "dislocated". Cylindrical digital inductive proximity switches are used and installed on the label pickup. At three positions on the lower side of the mechanism, online flexible parameter setting can be realized, and the height of the rising and falling height of the control mechanism can be adjusted in real time.

04 Labeling positioning and defect detection

At the labeling and inspection station, the labeling needs to be positioned to prevent labeling errors and waste due to differences in material orientation, angle, and position. After labeling is completed, it is necessary to check whether the labeling effect is qualified to ensure that the labeling is accurate and Smooth and wrinkle-free, Meiji's deep learning camera uses advanced optical technology to shoot and collect the labeling results. The highly integrated intelligent AI controller is equipped with multiple advanced machine vision algorithms to filter out false alarms and false points. Achieve accurate visual judgment, achieve labeling without labeling, automatic correction without labels and automatic label detection functions to prevent missed labeling and label waste.

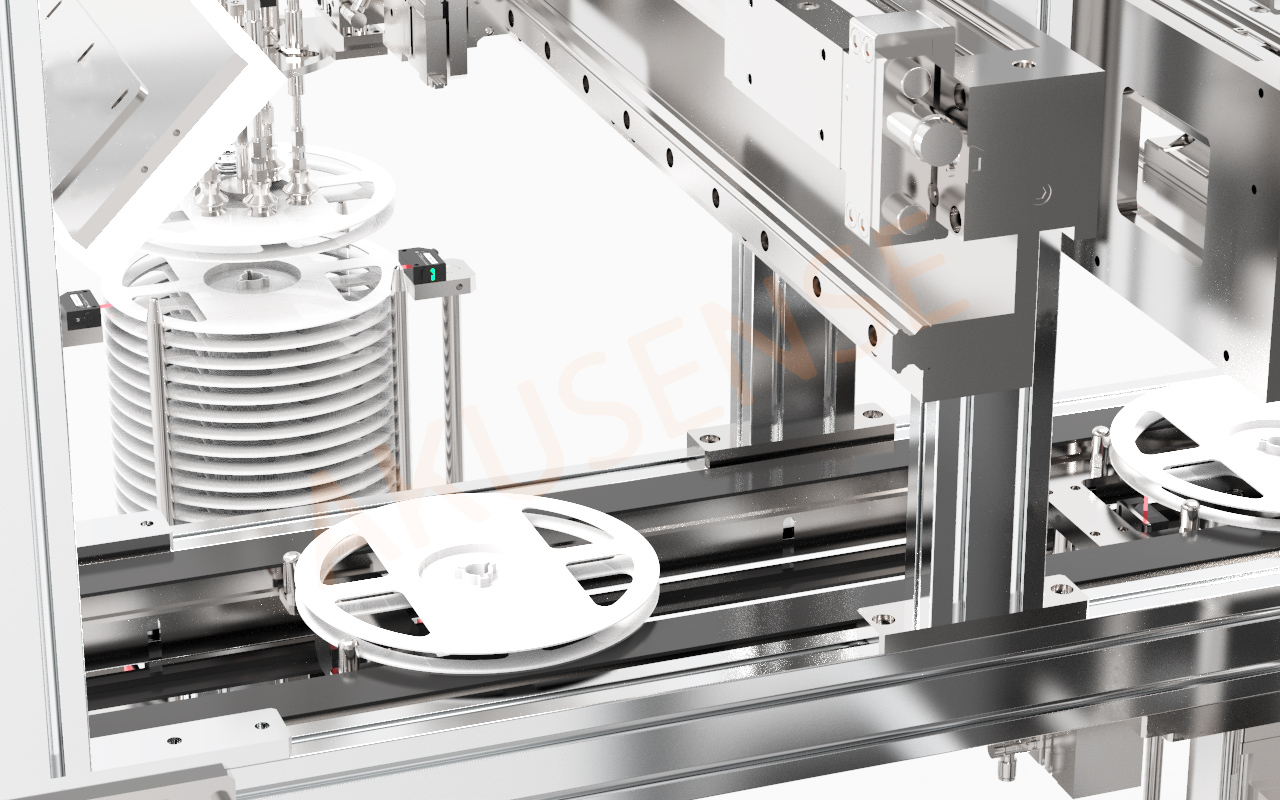

05 Monitoring of defective products placed full of materials

After the deep learning camera performs labeling OK/NG detection, the defective labeled products need to be captured by the robot to a specific placement location. A sensor needs to be installed here to detect the full status of the defective product station. The shape and placement order of products are highly uncertain, and packaging materials often have high reflectivity. PTE series through-beam photoelectricity can be installed here to monitor the material level status of the workstation, and new containers can be replaced in a timely manner for loading.

+86 18188641602