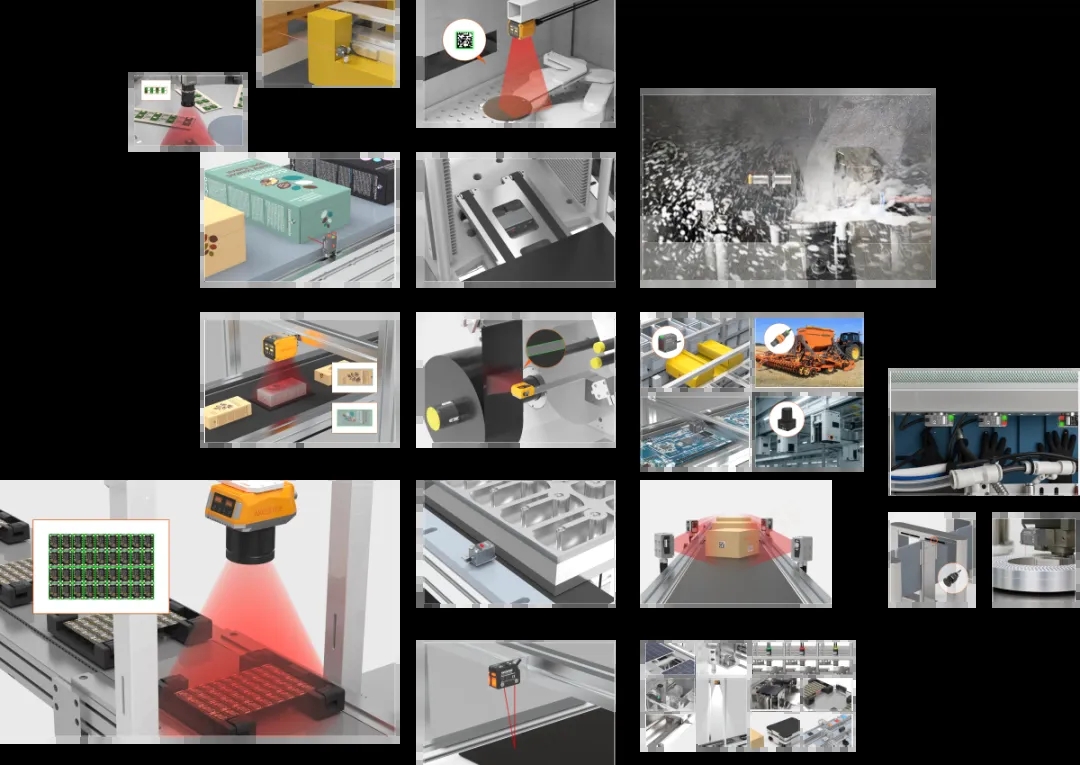

In automated production lines, robots must accurately locate and pick up mesh cloth positioned at specific spots.

Challenge: Detecting Mesh Cloth with Irregular Holes

Mesh cloth often features holes of varying sizes and colors, making detection difficult for traditional point-spot sensors. These sensors may fail to detect the cloth due to hole interference or color complexity. To overcome this, a large spot background suppression photoelectric sensor is essential.

Application Requirements:

1. Non-contact detection to confirm mesh cloth is in place before robotic pickup.

2. Installation distance within 70mm.

3. Large, varied holes in the mesh require a wide detection area.

4. Multiple mesh colors demand a sensor with high color tolerance.

Recommended Solution

Use a large spot background suppression photoelectric sensor, such as:

ESB-BL10 Series – Linear light spot, up to 65mm wide.

ESB-B30 Series – Circular light spot, up to 300mm in diameter.

Key Advantages

1. Large Light Spot Coverage Wide spot ensures part of the beam always hits the mesh, even with irregular holes—reducing missed detections.

2. Background Suppression Accurately distinguishes mesh from background (e.g., equipment, floor) and performs well despite color variation or lighting changes.

3. High-Precision Detection Advanced optical analysis identifies mesh structure while ignoring holes, ensuring reliable detection.

4. Stable & Reliable Performance Built with high-quality components and advanced signal processing for long-term accuracy and durability.