A gasket in a bolted joint is a thin, flat ring-shaped or sheet-like part, usually made of metal, rubber, or plastic.

The function of the screw washer is to increase the contact area, give the nut a force after the nut is tightened, increase the friction between the nut and the bolt, and at the same time prevent the screws and other parts from loosening and play a protective role; During the installation process, it is inevitable that there will be missing installations, so special quality inspection is required.

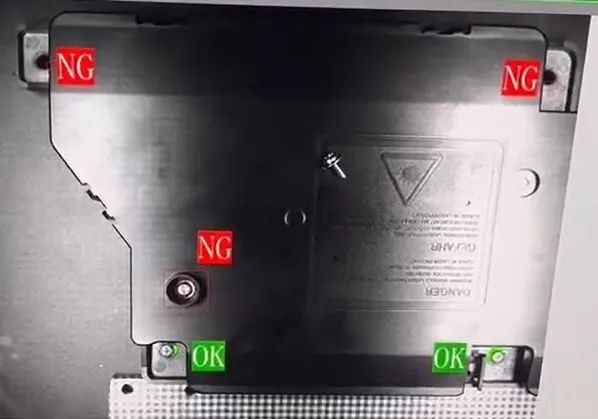

This article will share AKUSENSE’s visual inspection application solution for [the presence or absence of screws and washers on the workpiece]

Project requirements

1. Check whether the 5 screws on the workpiece have missing gaskets or are incorrectly installed.

2. The size of the workpiece is large, about 500mm in length, vertical and horizontal depth, and the horizontal planes where the screws are located are different.

Introduction to detection plan

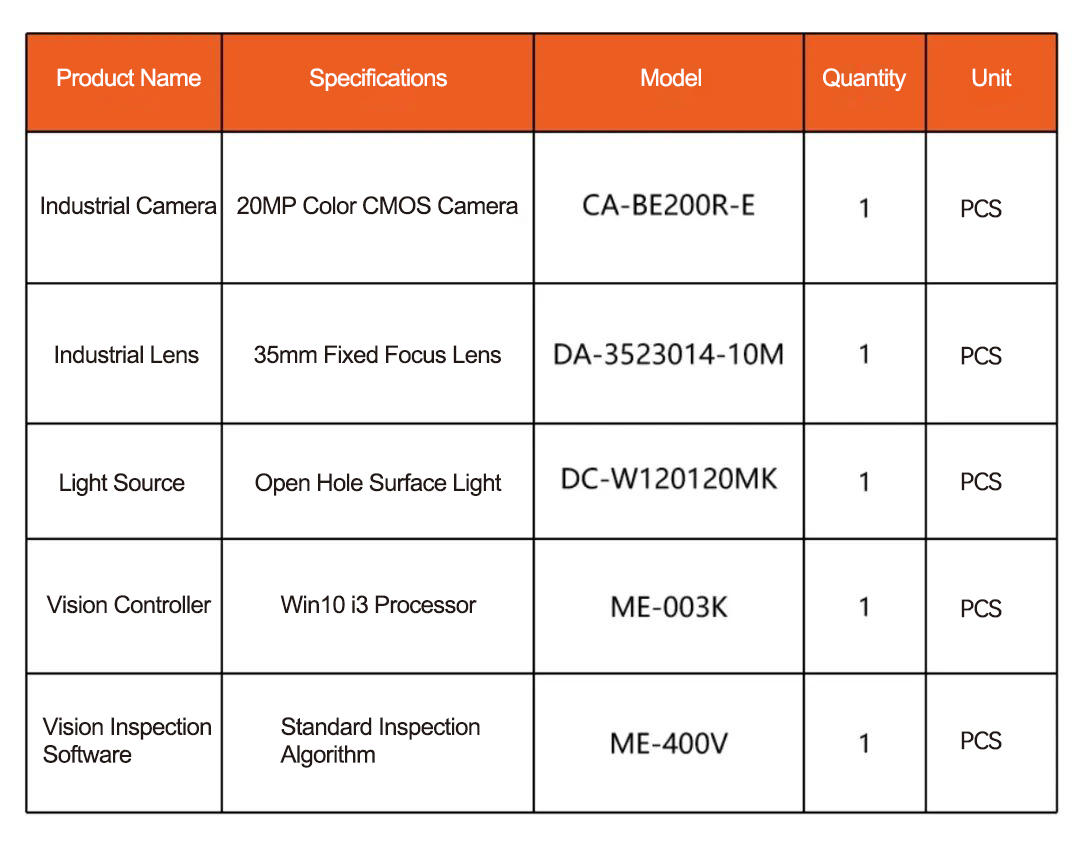

1. During the assembly process, the presence or absence of gaskets is accurately detected through a non-contact visual solution. The 35mm fixed-focus lens and large field of view image at once. There is no need to use two cameras for separate inspection, and defects in missing or incorrectly installed gaskets can be discovered in a timely manner.

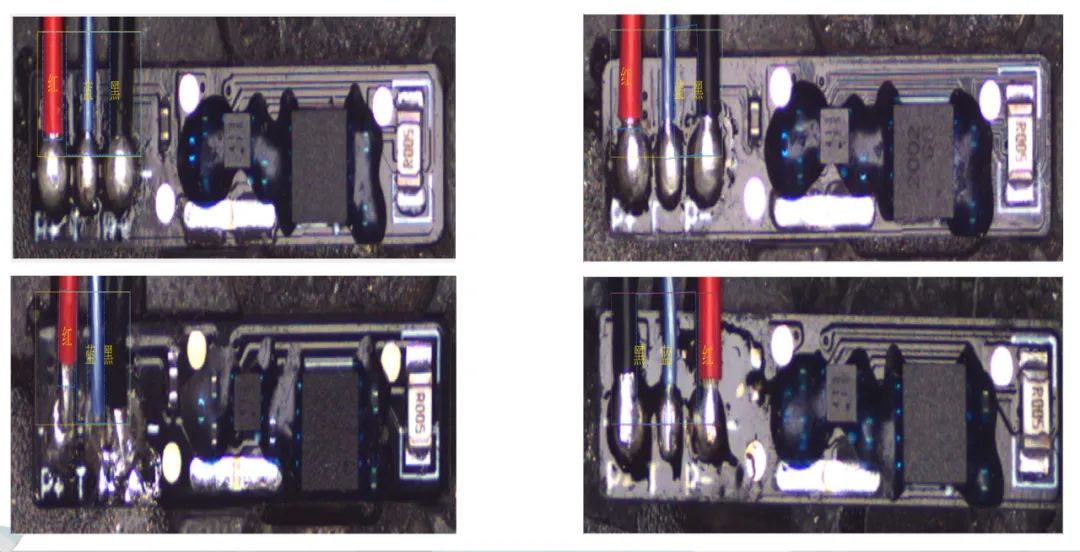

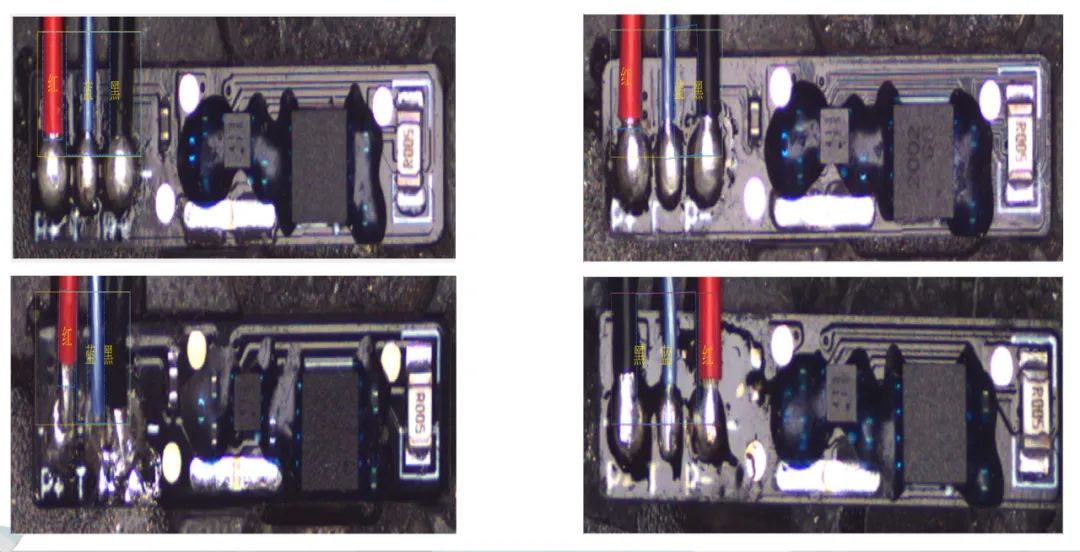

2. The detection principle is that under camera imaging, the gasket will be highly reflective, while the missing areas will not be highly reflective. Use the imaging characteristics of OK products as the basis for judgment. Objects to be inspected that are different from this characteristic will be judged as NG.

Overall detection effect