LiDAR: The "Eye of Wisdom" in Automated Warehousing and Smart Logistics in the Industry 4.0 Era

2025.02.09

Driven by the wave of Industry 4.0, automated warehousing and smart logistics are undergoing unprecedented transformations. In this evolution, LiDAR (Light Detection and Ranging) sensors play an increasingly vital role, acting as the "eye of wisdom" by providing precise environmental perception and decision-making support for warehousing and logistics systems.

1. LiDAR: From Autonomous Vehicles to Industrial Applications

LiDAR, a 3D sensor that detects surrounding environments by emitting laser beams and measuring reflected signals, has gained prominence in the autonomous driving field due to its high precision, resolution, and interference resistance. As technology matures and costs decline, LiDAR is expanding from autonomous vehicles to industrial applications. In the Industry 4.0 era, automated warehousing and smart logistics demand higher precision, real-time responsiveness, and reliability, which LiDAR effectively meets.

2. LiDAR Applications in Automated Warehousing

In automated warehousing systems, LiDAR is utilized in the following areas:

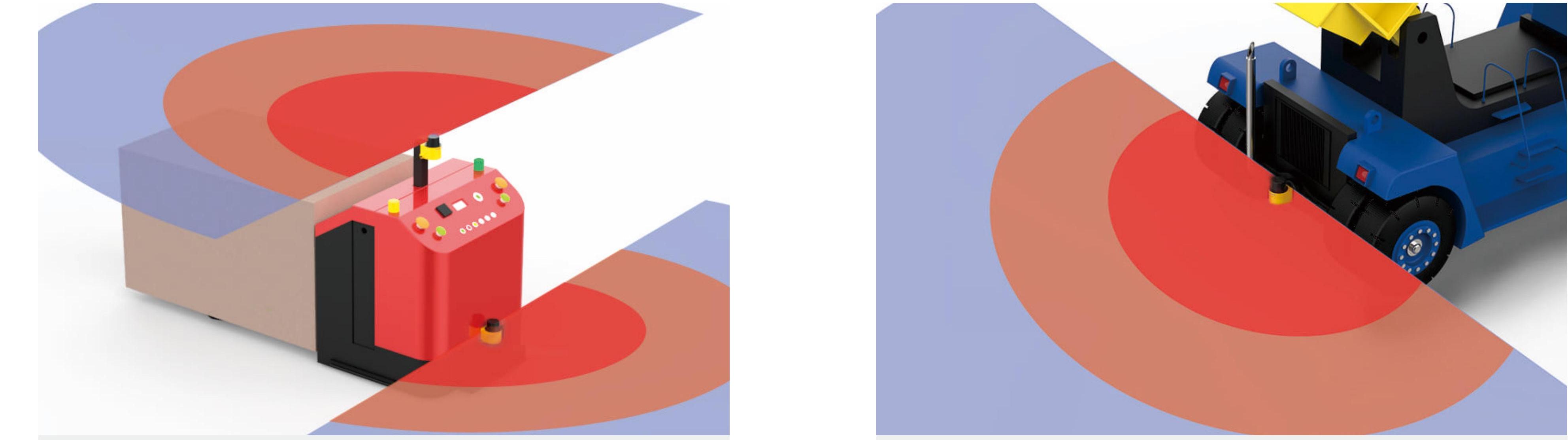

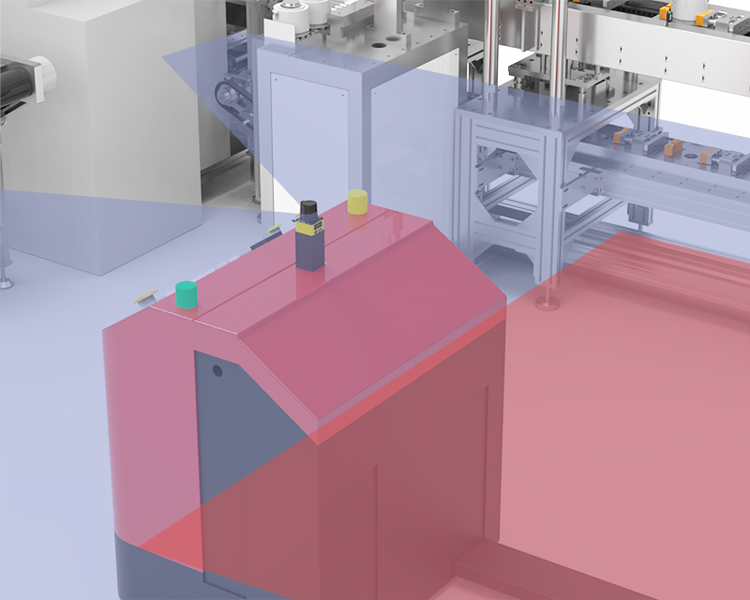

AGV Navigation & Obstacle Avoidance: LiDAR provides high-precision environmental maps and real-time positioning for Automated Guided Vehicles (AGVs), enabling autonomous navigation and obstacle avoidance, enhancing warehouse efficiency and safety.

Goods Identification & Sorting: LiDAR captures 3D information of goods and, combined with image recognition technology, enables automatic identification and classification, improving sorting efficiency and accuracy.

Inventory Management & Stocktaking: LiDAR scans the warehouse to generate high-precision inventory maps, enabling real-time monitoring and automatic stocktaking, boosting inventory management efficiency.

3. LiDAR Applications in Smart Logistics

LiDAR's applications in smart logistics are even broader:

Autonomous Delivery Vehicles: LiDAR equips autonomous delivery vehicles with environmental perception and path planning capabilities, enabling unmanned last-mile delivery and reducing logistics costs.

Smart Forklifts: LiDAR enhances forklift automation, enabling automatic loading, unloading, and handling of goods, improving logistics efficiency.

Logistics Park Management: LiDAR provides real-time monitoring for logistics parks, optimizing vehicle scheduling, path planning, and safety management, improving park operations.

4. Future Trends in LiDAR Technology

The future development of LiDAR technology will focus on:

Miniaturization & Cost Reduction: As technology advances, LiDAR’s size and cost will continue to decrease, making it easier to integrate into various devices and systems.

Higher Performance & Multi-functionality: LiDAR will offer higher detection precision, longer ranges, and additional functionalities such as speed measurement and object recognition.

Sensor Fusion: LiDAR will integrate with other sensors (e.g., cameras, radar) to provide more comprehensive and precise environmental awareness.

5. Conclusion

As a key sensor in the Industry 4.0 era, LiDAR is driving revolutionary changes in automated warehousing and smart logistics. With continuous technological advancements and decreasing costs, LiDAR will play a pivotal role across more industrial applications, propelling the intelligent transformation of Industry 4.0.

Related Products

+86 18188641602