TBL Proximity Sensors: Metal Detection Experts for Extreme Environments

2025.07.29

TBL Series: Your Metal Detection Expert for Extreme Industrial Environments

Solve Industrial Automation Challenges in Harsh Conditions

When standard inductive proximity sensors fail in oil contamination, malfunction under vibration,

or shut down in high-heat environments – what's your solution?

Oil-Resistant & Reliable Detection

In metalworking coolant-saturated CNC machines, TBL sensors resist fluid penetration that causes conventional sensors to crack, misfire, or burn out.

Our triple-shielded construction prevents:

Premature aging from cutting fluid immersion

Signal errors from oil infiltration

Electrical failure in wet environments

Multi-Scenario Adaptability

From CNC machining centers to high-pressure washdown zones and automated parking systems,

TBL delivers unmatched flexibility across industries:

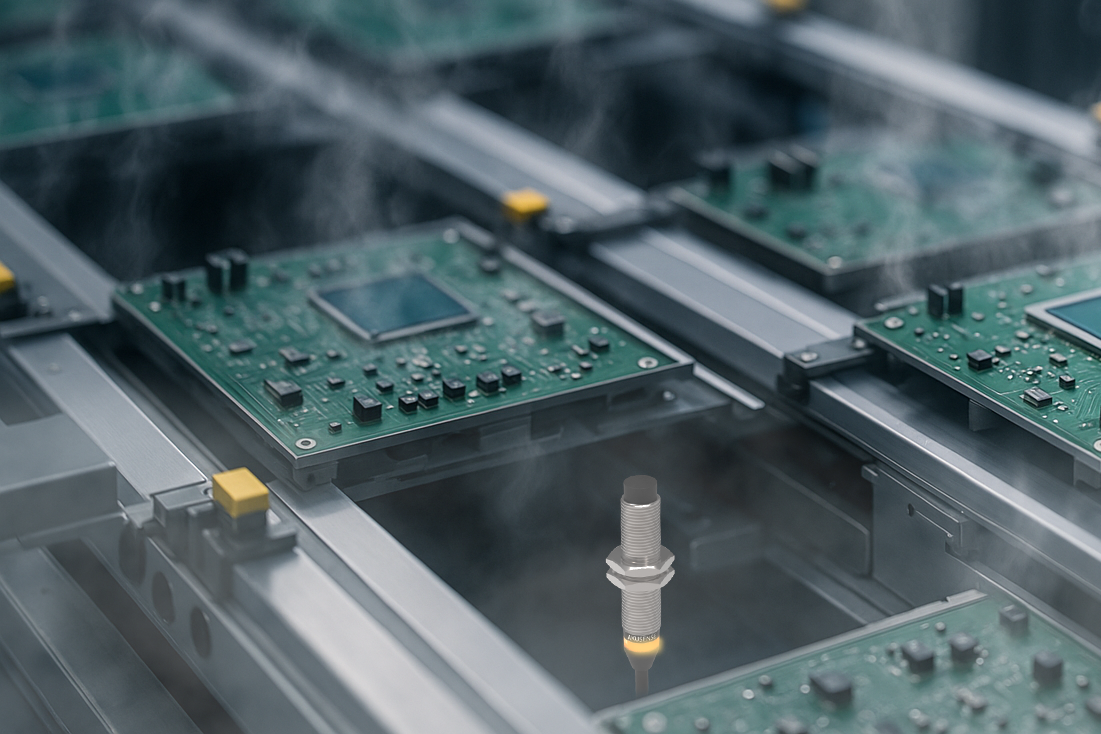

High-Temp Applications (85°C Rating)

Embedded in PCB drying ovens, TBL sensors:

✓ Track board position via NTC hardware compensation

✓ Maintain ±1mm accuracy at 85°C

✓ Enable precise process timing with smart thermal algorithms

Cryogenic Performance (-40°C Capability)

In outdoor smart parking facilities:

✓ Detects vehicles at -40°C

✓ Ensures instant gate response

✓ Eliminates weather-related downtime

CNC Machining

Integrated in spindle guards/tool changers:

✓ Resists water-/oil-based coolants

✓ Monitors tool positioning

✓ Prevents false signals from fluid ingress

Agricultural Machinery

In gearboxes/rotating assemblies:

✓ Withstands ISO VG 220 lubricants

✓ Tracks component speed/position

✓ Survives high-vibration environments

Waste Handling Vehicles

For compactor mechanisms/bin lifters:

✓ 304 stainless steel housing

✓ Resists acidic/alkaline corrosion

✓ Functions at -20°C to 80°C with pressure wash capability

Why Choose TBL Inductive Sensors?

Extended Service Life : IP68/IP69K protection against fluids & particulates

Thermal Resilience : -40°C to 85°C operational range

Impact Resistance : 50g shock rating with <1ms response stability

Smart Connectivity : IO-Link enabled for predictive maintenance

Upgrade your harsh-environment applications with TBL Series – the ultimate industrial automation solution.

Related Products

+86 18188641602