The Millisecond Manufacturing Revolution: How Smart Code Reading Technology Empowers Automotive Industry Digitalization

2025.04.16

Abstract

This article explores the technological strengths and practical value of the AKUSENSE RCD20 Series fixed-mount smart code readers in the automotive manufacturing sector. By analyzing its patented algorithm system, adaptive parameter optimization, and Machine Vision Algorithm Engine™, the paper demonstrates how the RCD20 effectively overcomes complex code reading challenges in automotive production. Special focus is placed on its applications in component traceability, assembly line quality control, and supply chain management. In the context of Industry 4.0, this paper also forecasts the evolution of smart code reading technology and offers actionable insights for automotive manufacturers seeking intelligent identification solutions.

Introduction: The Challenge of Code Identification in Automotive Manufacturing

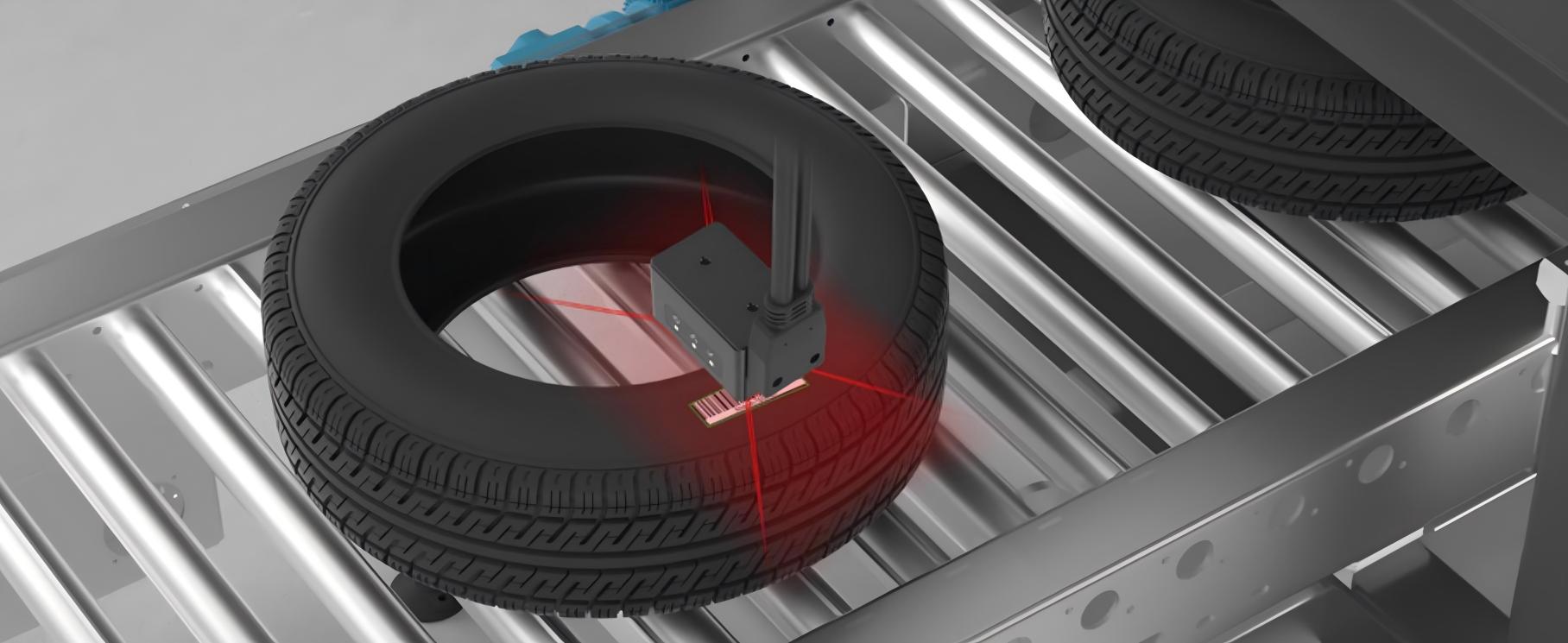

In today’s highly automated automotive production environments, rapid and accurate identification of product markings—including 1D barcodes, 2D codes, and DPM (Direct Part Marking) codes—has become a foundational element of intelligent manufacturing. According to the International Society of Automation (ISA), the average automotive part undergoes 6–8 code scans during its production lifecycle. However, traditional code readers struggle in scenarios involving metal-engraved markings or dark resin surfaces, with read rates of only 82–87%, creating significant bottlenecks in productivity.

The AKUSENSE RCD20 Series fixed-mount smart code readers present a disruptive solution. Leveraging its proprietary Machine Vision Algorithm Engine™ and adaptive parameter tuning system, RCD20 meets the stringent demands of automotive manufacturers. This paper presents a detailed technical analysis and evaluates how the RCD20 aligns with real-world industry requirements to drive smart manufacturing upgrades.

Core Technology Analysis: How RCD20 Solves Automotive Code Reading Challenges

1. Machine Vision Algorithm Engine™: A Breakthrough in Performance

The RCD20 Series is powered by the cutting-edge Machine Vision Algorithm Engine™, featuring three key innovations:

-

Multi-Algorithm Fusion Architecture

Combining traditional computer vision (CV) techniques with deep learning AI frameworks, this hybrid architecture is specially optimized for DPM codes. In tests on Data Matrix codes laser-etched on metal surfaces, the read rate reached 99.2%—far exceeding the industry average. -

Dynamic Load Balancing

With patented 20% Connect technology, the RCD20 maintains stable performance in low-contrast environments (<20%), ideal for reading under low lighting conditions, such as chassis component scanning. -

Angle Tolerance Mechanism

The unique Angle Strain algorithm supports reading at tilt angles up to ±60°, addressing challenges on production lines where part positioning limits reader angles.

2. Adaptive Parameter System for Engineering Flexibility

The AutoParameter system in the RCD20 supports over 860,000 parameter configuration combinations. This self-optimization capability ensures the reader adapts precisely to varying automotive production environments, improving both stability and accuracy across use cases.

3. Industrial-Grade Optical System Design

The RCD20’s 10-LED lighting array is engineered with “fail-safe” design principles inspired by automotive safety engineering:

-

Multi-Angle Illumination

A combination of 6 forward-facing and 4 side-facing LEDs eliminates shadow interference in deep cavities and recessed part surfaces. -

Spectral Optimization

The 625nm red-light wavelength is tailored for blue or black background markings commonly used in automotive manufacturing, improving contrast by over 40%. -

Smart Lighting Control

Lighting frequency adjusts automatically with conveyor speed to eliminate motion blur during high-speed scanning.

Key Application Scenarios in Automotive Manufacturing

1. Component Traceability and Quality Management

In vehicle identification number (VIN) recognition systems, the RCD20-AI120-LF100R model, with its 100–200mm working range and 120FPS high frame rate, enables seamless scanning on fast-moving lines. A major German automaker reported that integrating the RCD20 reduced their missed read rate from 1.8% to 0.05%, preventing an estimated annual loss of over ¥12 million from potential recalls.

2. Intelligent Assembly Line Control

Equipped with EtherNet/IP and Profinet protocols, the RCD20 integrates effortlessly into Manufacturing Execution Systems (MES). Its isolated I/O channels allow direct control of workstation activation. For instance, in seat installation lines, the reader triggers the retrieval of specific assembly instructions based on the scanned code—reducing misassembly by 67%.

3. Supply Chain & Logistics Management

In inbound logistics, RCD20’s TCP/IP support enables simultaneous data transfer to Warehouse Management Systems (WMS) and traceability platforms. With an IP65 protection rating, the device maintains performance in harsh dock environments. A Japanese OEM reported a 35% increase in warehouse entry efficiency following implementation.

Competitive Advantage and Industry Value Assessment

Compared to similar products, the RCD20 offers three distinct advantages for the automotive sector:

-

Total Lifecycle Cost Reduction

A compact, all-in-one design reduces installation space by 30%. Its MTBF (Mean Time Between Failures) exceeds 50,000 hours, significantly cutting maintenance costs. -

Future Compatibility

Supports industrial protocols such as Modbus TCP, facilitating seamless upgrades to IIoT infrastructure and aligning with automotive "digital twin" strategies. -

Sustainability

The 24VDC power system aligns with existing automotive plant standards and consumes 15–20% less energy than comparable products.

Future Outlook: The Evolution of Smart Code Reading in Automotive Manufacturing

Based on RCD20’s technical framework and broader industry trends, we forecast the following key directions for smart code reading technology:

-

Deeper Edge Computing Integration

Next-generation devices may embed lightweight AI models to enable simultaneous local quality inspection and code reading. -

Multimodal Sensing Integration

Combining ToF (Time of Flight) sensors and RFID for 3D spatial material tracking and full-scene perception. -

Evolving Adaptive Optics

Tunable wavelength lighting could address challenges posed by reflective metals and transparent packaging. -

Standardized Digital Twin Interfaces

Code readers will become crucial physical-digital mapping nodes, offering enriched metadata and contextual insights.

Conclusion

The AKUSENSE RCD20 Series fixed-mount smart code reader provides a robust solution to the complex code reading challenges of the automotive industry. With its innovative Machine Vision Algorithm Engine™ and adaptive parameter system, it excels in traceability, system reliability, and integration flexibility—making it a core enabler of smart manufacturing.

As automotive production trends toward flexible, customized, and digitized processes, smart code readers will play an increasingly pivotal role. Automotive manufacturers should incorporate reader performance metrics into their overall digital strategy. The RCD20’s technical capabilities and real-world deployments offer a valuable benchmark. Looking ahead, with the convergence of 5G-A and AI technologies, smart readers are poised to evolve from simple identification tools into intelligent sensing hubs—fueling the next wave of digital transformation in the automotive industry.

Related Products

+86 18188641602