Innovative Applications and Technological Breakthroughs of the RCD20 Series Fixed-Mount Smart Code Readers in the Photovoltaic Industry

2025.04.16

As a driving force behind global energy transformation, the photovoltaic (PV) industry demands unprecedented levels of production automation and traceability. In response, AKUSENSE has launched the RCD20 series fixed-mount smart code readers, equipped with an advanced Machine Vision Algorithm Engine™ and adaptive decoding capabilities. This series is redefining identification technologies across the entire PV manufacturing process. This article explores the RCD20’s technological advantages, application scenarios, and industry impact.

Unique Coding Challenges in Photovoltaic Manufacturing

The PV manufacturing environment is characterized by:

-

Highly reflective glass surfaces

-

Complex lighting conditions

-

High-speed production lines (often exceeding 2m/s)

-

Long-term outdoor usage requirements

Traditional code readers struggle to meet these challenges, facing three primary technical limitations:

-

Low Contrast Recognition

Direct part marking (DPM) on solar cells often results in poor contrast (under 20%), particularly on PERC and TOPCon cells where rear-side treatments reduce readability. -

Instability in Dynamic Scanning

During lamination, high temperatures (150–180°C) may cause material deformation, resulting in micron-level QR code displacement that requires real-time angular compensation. -

Multi-Code Compatibility

From silicon ingots to complete modules, the production line involves various code formats such as Data Matrix and QR Code, with inconsistent coding standards across different processes.

Core Technological Innovations of the RCD20 Series

Breakthroughs in the Machine Vision Algorithm Engine™

The RCD20 series is powered by AKUSENSE’s proprietary algorithm, optimized specifically for the PV industry. Its “20% Connect” technology utilizes a sub-pixel edge reconstruction algorithm to resolve blurred code edges caused by laser marking. In tests with solar wafers having only 18% contrast, the reader achieved a first-read success rate of over 98.7% (per ISO/IEC 15415 standards).

A standout feature is the angular strain compensation algorithm, which analyzes localized image distortion in real-time (at 120FPS sampling rate), automatically correcting viewing angle deviations within ±45°. This is especially effective in addressing code distortion caused by EVA film expansion and contraction during lamination.

Adaptive Optical System Engineering

The RCD20 integrates 10 high-performance LEDs with multi-spectrum modulation technology. It dynamically adjusts red light wavelength (620–630nm) and angle of incidence according to the reflective characteristics of PV glass (typically 91.5% transmittance for 3.2mm thick glass). In real-world tests, this design reduces misread rates in reflective environments to below 0.3%.

Two optical variants—short-focus (60–120mm) and long-focus (100–200mm)—cover identification needs from individual solar cells to full modules. On production lines with 182mm large-size wafers, the long-focus model enables efficient scanning of 4-cell linked arrays in a single capture.

In-Depth Application Scenarios in PV Manufacturing

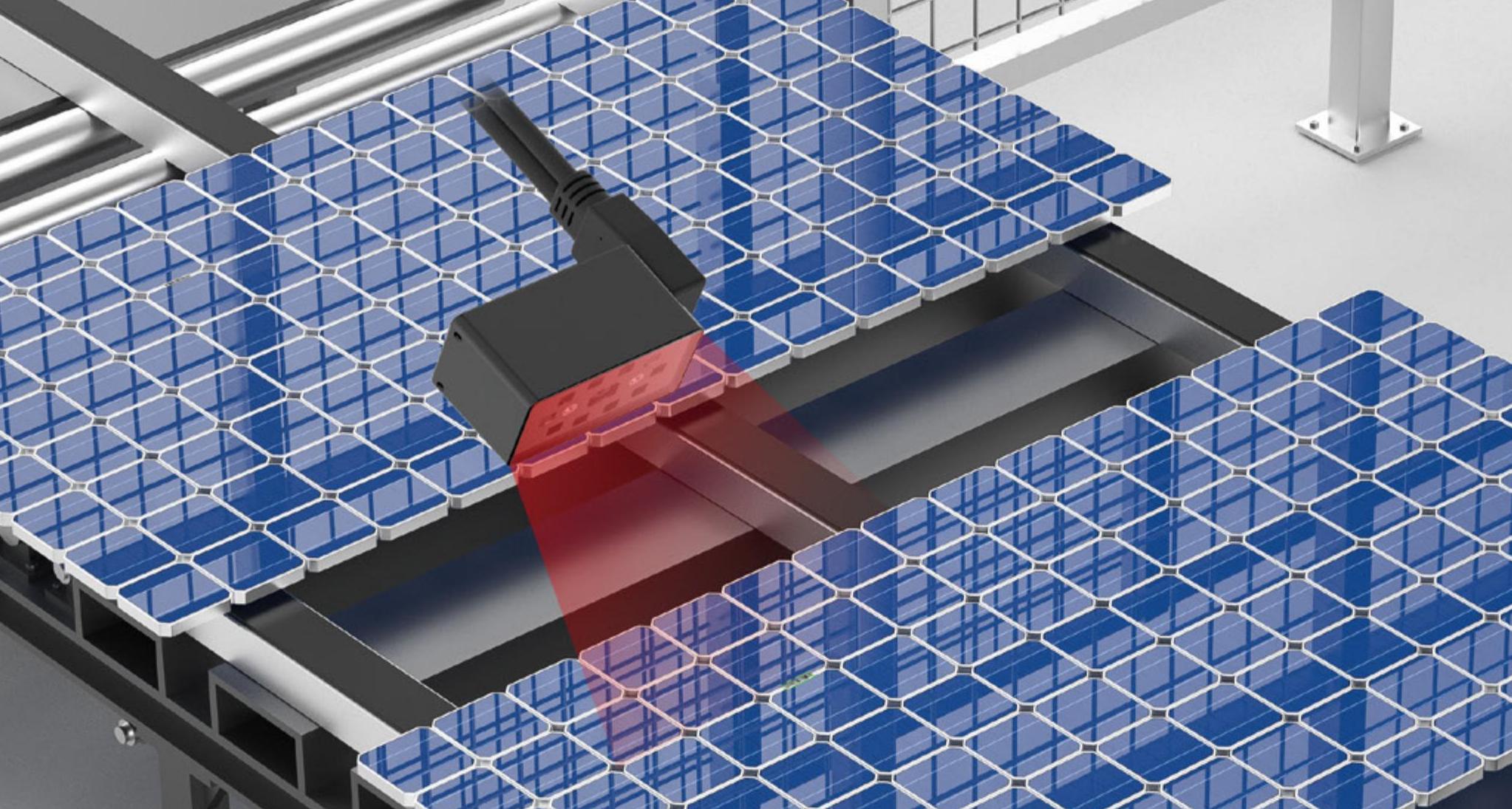

Solar Cell Production

During PECVD and screen-printing stages, the RCD20’s metal engraving decoding algorithm proves highly effective. Leveraging deep learning-assisted feature extraction, it distinguishes code marks from background textures (e.g., gridline shadows), improving recognition accuracy in silver paste-covered areas by 40%.

Module Assembly

To address code deformation caused by lamination heat, the RCD20 applies a black resin gray-code decoding technique. This models the relationship between material thermal expansion and image distortion, enabling temperature-compensated decoding. In real-case testing by a TOPCon module manufacturer, the reader maintained 99.2% stability at 85°C.

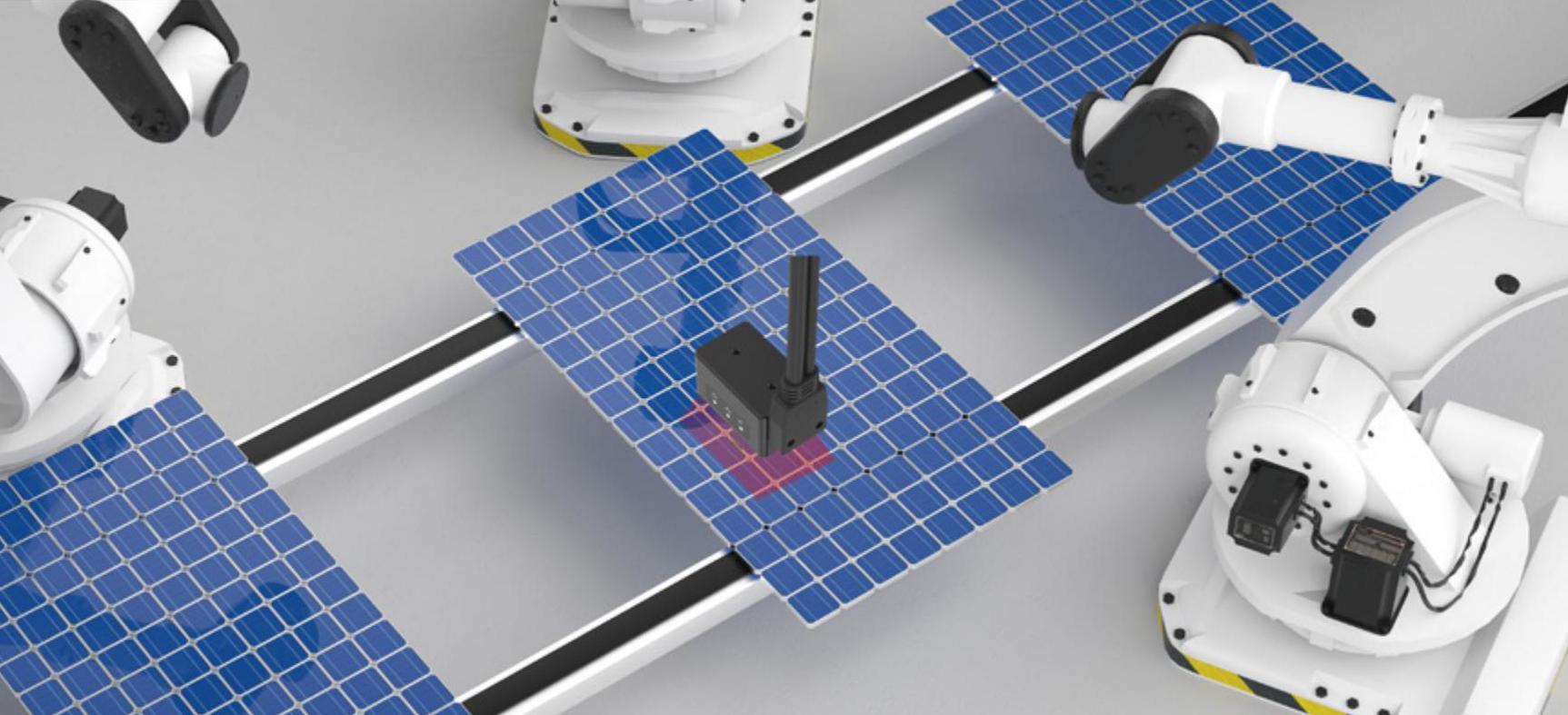

Outdoor PV Plant Traceability

Thanks to its IP65 protection rating and -10°C to 50°C operating range, the RCD20-E model is ideal for tracing inverter serial numbers in PV plants. With built-in Profinet protocol support, it connects directly to SCADA systems for real-time component-level energy output and traceability analytics.

Industry Value and Future Outlook

The RCD20 series delivers significant improvements in traceability accuracy and production efficiency. A top-5 global module manufacturer reported a 62% reduction in sorting misjudgments and a 15% increase in production cycle speed after adopting the system.

As PV technologies evolve toward HJT and perovskite structures, new demands will emerge for code reading solutions. AKUSENSE is actively exploring innovations in the following areas:

-

Quantum dot-enhanced multi-spectrum recognition

-

Curved surface decoding algorithms for flexible modules

-

Real-time data analytics platforms integrated with digital twins

The PV industry’s shift toward intelligent manufacturing is accelerating. With its algorithm-driven design and sector-specific engineering, the RCD20 series has become an indispensable part of the smart manufacturing ecosystem. Its successful deployment also sets a valuable precedent for identification technologies in broader renewable energy sectors.

Industry Insight: According to the ITRPV (International Technology Roadmap for Photovoltaics), by 2027, 92% of global PV manufacturing will integrate automatic identification technologies, with AI-driven smart readers accounting for 75% of market share. The RCD20 series is well-positioned to meet and lead this emerging trend.

Related Products

+86 18188641602