As Industry 4.0 reshapes global manufacturing, intelligent recognition technology is emerging as a critical bridge between the physical and digital worlds, undergoing unprecedented advancements. This article provides an in-depth analysis of the technological innovation framework of the AKUSENSE RCD20 Series Fixed-Mount Code Reader, highlighting its pivotal role in the intelligent manufacturing ecosystem and exploring its profound impact on the future of industrial automation. Through a professional dissection of its patented algorithms, adaptive system, and industrial-grade design, this guide offers industry professionals both academic insight and practical value.

1. Evolution of Intelligent Code Reading Technology in the Context of Industry 4.0

As traditional industrial automation transitions into intelligent manufacturing, object recognition and data acquisition technologies have undergone three significant evolutionary stages: from early Optical Character Recognition (OCR) to barcode technology, and now to multidimensional codes and Direct Part Marking (DPM). This progression closely aligns with the core demands of Industry 4.0—real-time data exchange, flexible production, and full lifecycle management.

The RCD20 Series leverages a cutting-edge machine vision algorithm engine, representing the pinnacle of third-generation recognition technology. Its breakthroughs are evident in two key areas:

-

Integration of over 20 patented decoding algorithms (including 20% Connect, 30% Connect, and low-contrast decoding), overcoming traditional code readers’ recognition challenges in complex industrial environments.

-

AI-driven Auto Parameter system, capable of automatically optimizing more than 860,000 parameter configurations, enabling human-like visual adaptability.

2. Core Technological Innovations of the RCD20 Series

2.1 Architectural Breakthrough in Adaptive Algorithm System

The RCD20 Series features a hierarchical recognition architecture:

-

Sensor Layer: Utilizes a 1280×960 global shutter CMOS sensor paired with a 10-unit high-performance red LED illumination matrix, ensuring stable image capture at a high frame rate of 120 FPS.

-

Algorithm Layer: Proprietary “Angle Distortion Compensation” and “Metal Engraving” algorithms effectively address common industrial challenges such as deformed or reflective QR codes.

-

Decision Layer: The AutoCheck system enables automatic code format recognition, distinguishing between Data Matrix, QR Code, and 13 types of 1D barcodes while leveraging a predefined template library to boost recognition speed by over 40%.

2.2 Engineering Excellence for Industrial-Grade Reliability

The RCD20 Series is designed to meet stringent industrial requirements:

-

Environmental Adaptability: Ensures stable performance within a temperature range of -10°C to 50°C, with an IP65-rated enclosure for resistance to dust and water splashes.

-

Versatile Interfaces: Supports USB 2.0, RS232, Ethernet, and industrial protocols (Profinet, Modbus TCP) to facilitate seamless data integration across multiple levels.

-

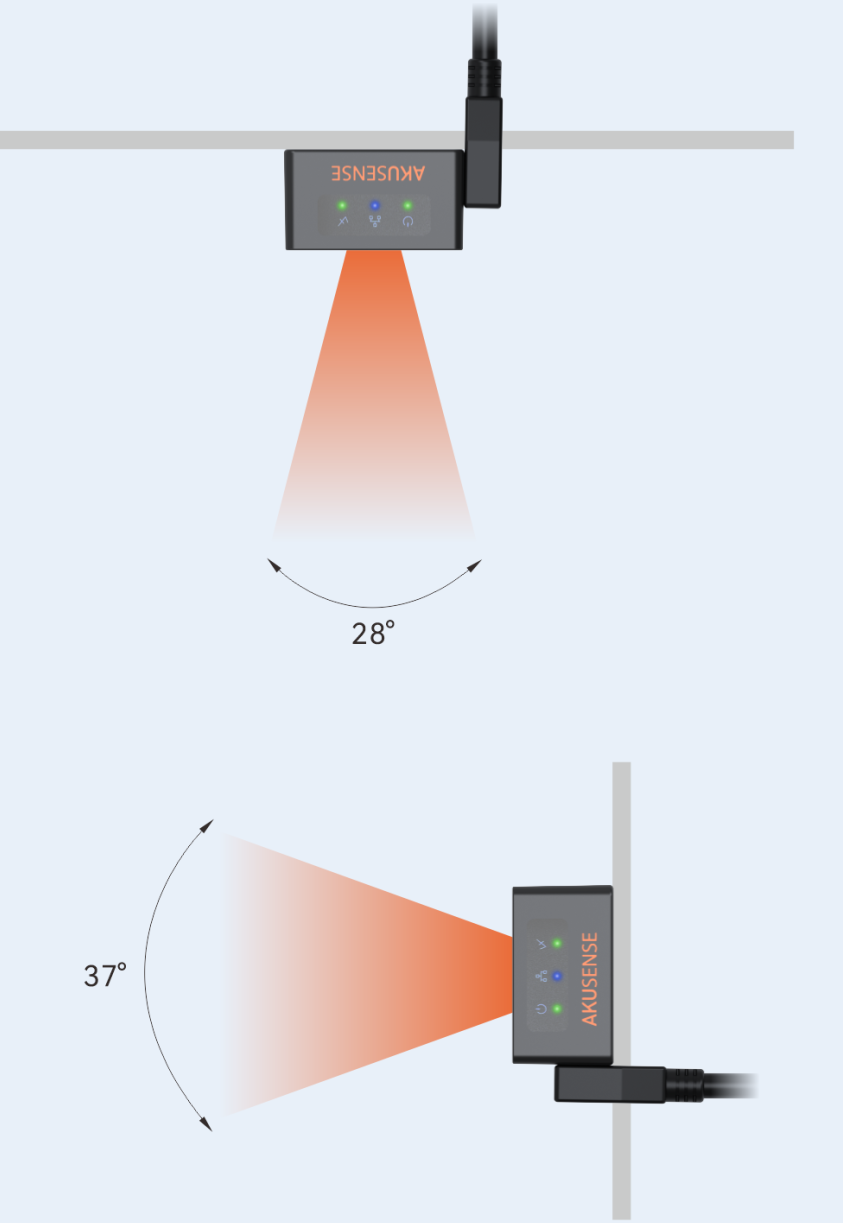

Optical System Optimization: A 37°×28° field of view with a fixed-focus design ensures optimal imaging quality at working distances of 60–200 mm (depending on the model).

3. Application Adaptability in Key Industrial Scenarios

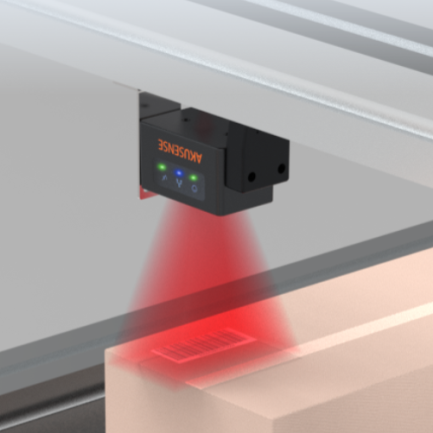

Field research in industries such as 3C electronics and automotive manufacturing has demonstrated the distinct advantages of the RCD20 Series:

3.1 High-Density Electronic Assembly Lines

In PCB traceability applications, the proprietary “Black Resin Low-Contrast” algorithm successfully resolves the challenge of QR codes obscured by silicone coatings, improving the reading rate from 72% (with conventional devices) to 99.3%.

3.2 New Energy Vehicle Battery Production

For DPM applications on metal casings, the specially optimized metal engraving algorithm enhances recognition stability under reflective conditions by 58%, significantly reducing misjudgment-related production downtime.

3.3 Smart Photovoltaic Component Production Lines

The long-focus model (LF100R) reliably reads 2mm × 2mm micro Data Matrix codes on silicon wafers at a working distance of 100–200 mm, even when moving at speeds of 1.5 m/s, meeting the demands of high-speed production lines.

4. System Integration Prospects in the Industrial Internet of Things (IIoT)

As a fundamental data acquisition node in Industry 4.0, the RCD20 Series achieves deep integration with intelligent manufacturing systems through protocol compatibility:

-

Seamless PLC Integration: Direct Ethernet/IP connectivity for real-time equipment status monitoring.

-

Automated Data Uploading: Built-in FTP client enables automatic transmission of reading logs to MES databases.

-

Closed-Loop Quality Control: Isolated I/O (1 input, 1 output) ensures linkage with safety control systems.

Looking ahead, as 5G industrial applications become widespread, the RCD20 Series can be further upgraded into an edge computing node, enabling localized data processing and decision-making while reducing reliance on cloud-based systems and minimizing latency.

Conclusion: The Future Trajectory of Intelligent Code Reading Technology

In the grand narrative of Industry 4.0, the AKUSENSE RCD20 Series represents a new generation of fixed-mount code readers that transcend conventional tool functions to become essential components of intelligent manufacturing’s data infrastructure. Their value extends beyond mere "reading accuracy" to encompass:

-

High-fidelity data sources for digital twin applications.

-

Rapid reconfiguration capabilities for flexible manufacturing.

-

Tamper-proof evidence chains for quality traceability.

Over the next three years, as 5G-AURC (Ultra-Reliable Low-Latency Communication) technology becomes commercially viable, fixed-mount code readers are expected to evolve into the neural endpoints of smart factories, realizing the vision of "one code per object, everything interconnected.