Smart Code Readers in the Era of Industry 4.0:Technological Innovation in Intelligent Sensing and Efficient Decoding

2025.03.22

Introduction: Evolving Sensor Demands in Industry 4.0

Industry 4.0, with its emphasis on smart manufacturing, drives the digitalization, networking, and intelligence of production processes. As the "eyes" of industrial automation, sensor performance directly determines the accuracy and efficiency of data acquisition. Traditional code readers often struggle with decoding speed and environmental adaptability in complex industrial scenarios. However, the latest generation of intelligent code readers, integrating AI algorithms, multi-modal perception, and high-performance hardware, are becoming pivotal in advancing industrial automation.

This article explores the technological breakthroughs and application potential of AKUSENSE’s RCD-AI series intelligent code readers in the context of Industry 4.0.

Technological Innovations: Core Advancements of Intelligent Code Readers

1. Millisecond-Level Decoding and Edge Computing Capability

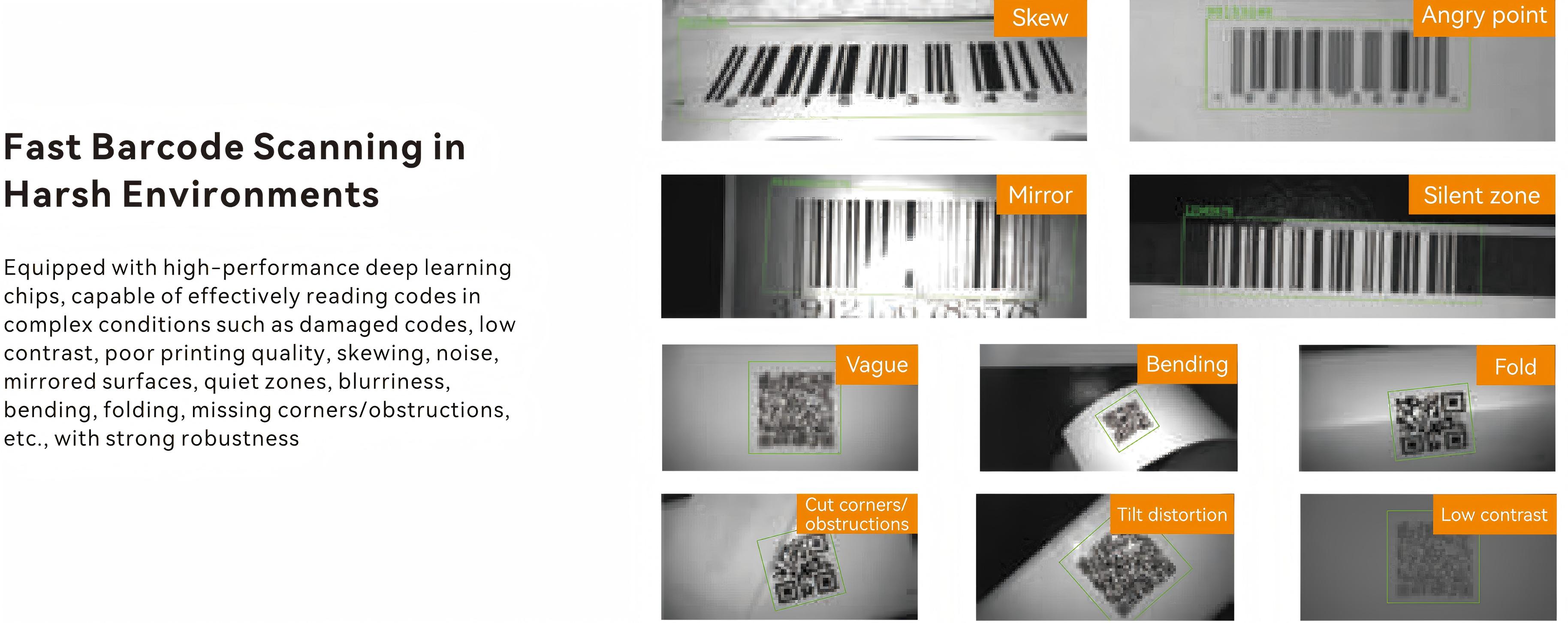

Real-time performance is critical in Industry 4.0. The RCD-AI series is powered by a Cortex quad-core processor (1.8GHz per core) and proprietary deep learning algorithms, achieving one-dimensional barcode decoding speeds of 10ms—three times faster than traditional readers (30ms). Its AI-driven image recognition technology, such as ME-min A-grade sampling, supports a precision of 0.06mm, allowing for the identification of ultra-small codes (e.g., 3mil Code 39) in industries like precision electronics and medical devices.

2. Adaptive Multi-Scenario Performance and Displacement Perception Technology

The complexity of industrial environments—such as variations in lighting and product height—demands robust sensor adaptability. The RCD-AI series achieves this through:

-

Dual-Mode Focusing: Supports mechanical and liquid lens autofocus with multiple focal lengths (8mm, 12mm, 16mm), covering detection distances from 40mm to 1000mm, accommodating diverse installation requirements.

-

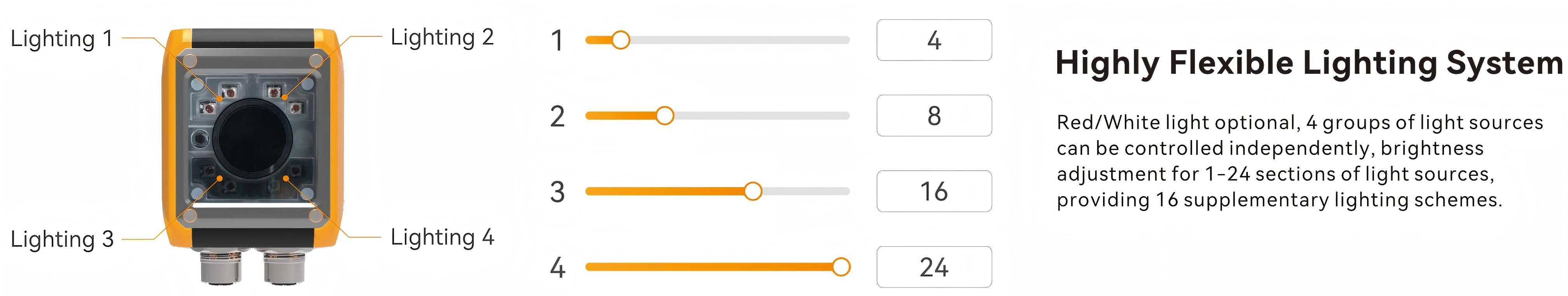

Polarized Light Source and Multi-Spectral Compatibility: Offers non-polarized, polarized red/white light combinations, effectively addressing challenges such as reflections on metallic surfaces and transparent material barcode recognition.

-

Displacement Compensation Algorithm: Integrates vibration and tilt sensors with AI-based dynamic calibration, ensuring stable barcode reading in scenarios with mechanical arm movement or conveyor belt vibrations, reducing error rates caused by displacement deviations.

3. Industrial IoT (IIoT) Networking and Protocol Compatibility

The RCD-AI series supports networking of up to 32 devices via a master-slave architecture, enabling centralized data aggregation and transmission in line with Industry 4.0’s distributed control systems. It is compatible with over ten industrial communication protocols, including Profinet, Ethernet/IP, and ModBus TCP, allowing seamless integration with PLCs and MES systems for closed-loop factory data management.

Application Scenarios: From Flexible Production Lines to Smart Warehousing

1. Robotic Guidance and Precision Assembly

In automotive manufacturing, robotic arms must rapidly identify QR codes (e.g., DataMatrix) on components for precise handling. The RCD-AI2000 series, featuring a high-resolution 5472×3648 sensor and AI-driven dynamic focusing, can pinpoint micro-scale barcode positions within 0.1 seconds, supporting high-speed conveyor lines (60 codes per second).

2. Logistics Sorting in Complex Environments

In warehousing, barcodes are often obscured by damage, folds, or inconsistent lighting. The RCD-AI100-S series, equipped with a cyclic decoding mode (preloaded with multiple algorithmic parameters) and non-polarized white light sources, can penetrate packaging films and eliminate shadow interference, maintaining a 99.5%+ reading accuracy in dark-field or high-contrast environments.

3. Pharmaceutical Industry Traceability

Medical packaging requires precise reading of direct part marking (DPM) codes. The RCD-AI100-F(HF) series, incorporating a 180mm wide-angle light source and deep learning algorithms, can accurately recognize dot peen codes and matrix-based markings, ensuring full compliance with batch traceability and regulatory standards.

Industry Trends: Deep Integration of AI and Edge Computing

Industrial sensors are evolving from single-function devices to intelligent perception terminals. The RCD-AI series exemplifies several key industry trends:

-

Edge AI-Enabled Real-Time Decision Making: The built-in quad-core processor supports localized data processing, reducing cloud dependence and meeting industrial low-latency requirements.

-

Multi-Sensor Fusion: Integrates vibration, temperature, and RFID sensors to construct comprehensive data models, laying the groundwork for predictive maintenance.

-

Sustainable Design: With power consumption as low as 5W (RCD-AI100-S series) and an IP67 protection rating, it operates reliably in harsh environments (-20°C to 70°C).

Conclusion: The Future Role of Intelligent Code Readers

Under the Industry 4.0 framework, intelligent code readers are more than just data acquisition tools—they serve as crucial nodes connecting the physical world with digital twins. Through the RCD-AI series, AKUSENSE demonstrates the deep fusion of high-precision sensing, adaptive algorithms, and industrial connectivity. As 5G and digital twin technologies continue to advance, intelligent code readers will further evolve toward an integrated "perception-decision-execution" model, solidifying their role as enablers of smart manufacturing ecosystems.

Related Products

+86 18188641602