Loading comments...

Search type :

Pages ()

Catalogs ()

search.drawings ()

Manuals ()

Products series ():

All Products seriesModel ():

The High-Precision Measurement Revolution in the Industry 4.0 Era: Technological Breakthroughs and Future Applications of the ACC10 Series Spectral Confocal Displacement Sensor

2025.03.15

Introduction: Precision Demands and the Evolution of Measurement Technology in Industry 4.0

Industry 4.0, driven by intelligent interconnectivity, is transforming manufacturing towards data-driven, real-time decision-making. In this context, high-precision measurement technologies serve as a fundamental pillar of smart manufacturing. Traditional contact-based sensors struggle with wear, environmental interference, and the inability to meet the demands of micron- and nanometer-level dynamic measurements. In contrast, non-contact optical sensors stand out due to their high resolution and strong anti-interference capabilities. Among them, spectral confocal displacement sensors have emerged as a cutting-edge technology for precision measurement, leveraging unique spectral analysis principles.

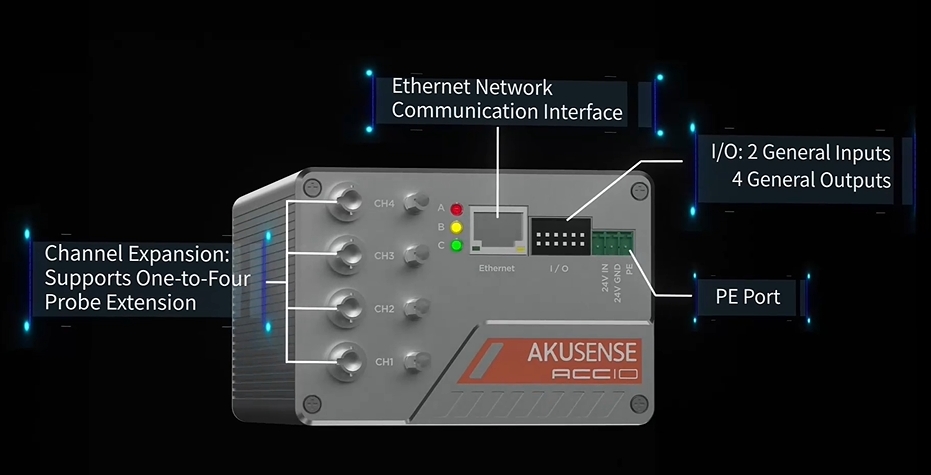

As an innovator in this field, AKUSENSE introduces the ACC10 Series Spectral Confocal Displacement Sensor, featuring linear accuracy of 9μm, repeatability of 50nm, four-channel simultaneous measurement, and compatibility with over ten probe options. This series not only fills the technological gap in ultra-precision industrial measurement but also offers a modular design that provides a new solution for flexible manufacturing in Industry 4.0.

Technical Principles: The Scientific Core of Spectral Confocal Displacement Measurement

The essence of spectral confocal technology lies in the synergy between a dispersive lens and a spectrometer, enabling nanometer-level displacement measurement through wavelength analysis of reflected light. The core working principle can be summarized as follows:

- A broadband light source emits a multi-wavelength beam, which, after passing through a dispersive lens, forms axially dispersed focal points.

- The measured object reflects the light back through the same lens, where a spectrometer analyzes the wavelength peak.

- A linear relationship between wavelength and displacement allows precise positioning through algorithmic conversion.

Compared to traditional laser triangulation, spectral confocal technology eliminates angle dependency and is resistant to surface reflection interference, making it especially suitable for complex surfaces such as transparent, mirror-finish, and multi-layered materials. The ACC10 Series further enhances this foundation by optimizing its optical system to achieve 50nm repeatability and enabling four-channel parallel measurement, significantly improving detection efficiency in industrial applications.

Industry 4.0 Applications: The Adaptability and Practical Value of the ACC10 Series

1. Real-Time Quality Monitoring in Smart Manufacturing

In automotive battery electrode inspection, the ACC10 Series leverages multi-probe collaboration (e.g., 0.5mm ultra-small probes for narrow spaces) to monitor electrode thickness in real-time (accuracy ±1μm). Measurement data is synchronized with MES systems, enabling dynamic process adjustments and eliminating batch risks caused by traditional sampling methods.

2. Precision Alignment in Semiconductor Packaging

For solder ball height measurement in chip packaging—where repeatability requirements are ≤100nm—the ACC10 Series ensures stable performance in high-speed production environments through its 50nm repeatability and anti-vibration design, enhancing packaging yield rates to over 99.98%.

3. Rapid Adaptation for Flexible Production Lines

With over ten modular probe options (e.g., high-temperature probes, long-distance probes), the ACC10 Series allows seamless transition across industries such as 3C electronics, photovoltaics, and medical devices. This minimizes redundant equipment investments and aligns with Industry 4.0’s "small-batch, multi-variety" production trend.

Academic Insights: The ACC10 Series as a Technological Breakthrough and Industry Benchmark

The ACC10 Series not only represents a milestone in spectral confocal technology but also sets new benchmarks in industrial metrology. By combining precision optics, advanced signal processing, and AI-driven data analytics, it offers significant insights for future research and industrial applications.

Future Challenges and Trends: From a Measurement Tool to a Data-Driven Node

Despite the significant advancements in spectral confocal technology, its deeper integration into Industry 4.0 still faces several challenges:

- Data Fusion Bottleneck: How to integrate high-precision measurement data with AI models for predictive maintenance.

- Cost and Market Penetration: High-end sensors remain concentrated within leading enterprises, necessitating standardized interfaces to lower integration barriers.

In the future, with the rise of 5G-MEC (Multi-Access Edge Computing) and Digital Twin technologies, the ACC10 Series is poised to evolve beyond a standalone measurement tool into an intelligent perception terminal. By enabling real-time data streams, it will contribute to precise virtual factory mapping and ultimately achieve a closed-loop control system for “perception-decision-execution.”

Conclusion: Precision is Competitiveness—Sensors Shape the Future of Manufacturing

At its core, Industry 4.0 is about conquering uncertainty—leveraging data and algorithms to control production fluctuations within physical limits. The AKUSENSE ACC10 Series, with its scientifically rigorous design and industrial-grade reliability, not only redefines the boundaries of displacement measurement precision but also unlocks the limitless potential of optical sensing in smart manufacturing.

When every micron of deviation is precisely captured, the era of absolute certainty in industrial production may finally become a reality.

Related Products

+86 18188641602

Akusense Technology Co., Ltd.

- INDUSTRIES

- Energy Industry

- Semiconductor Industry

- Industrial Robots

- Electronics Industry

- Logistics Industry

- Medical Technology

- Packaging Industry

- Automotive Industry

- PRODUCTS

- Detection Sensors

- Measuring Sensors

- Safety

- Special Sensors

- Vision & Identification

- Network & Connection

- Accessories