AKUSENSE Safety Door Locks: Intelligent Solutions for Door Status Monitoring and Pharmaceutical Filling Applications

2025.02.22

Introduction

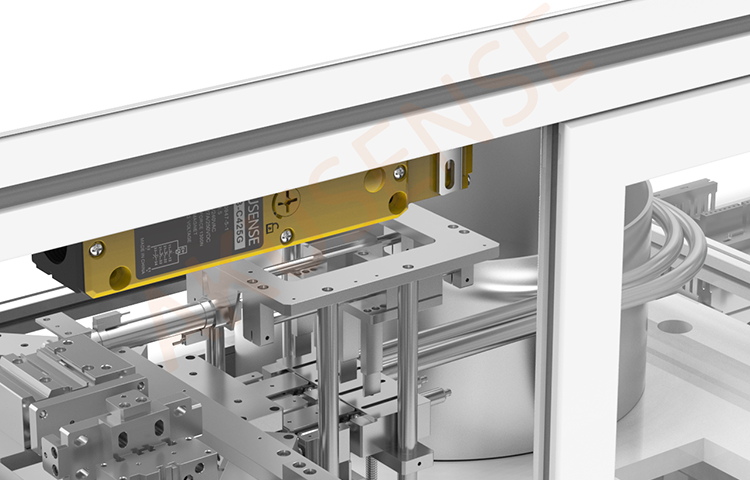

Amid the accelerating automation transformation in the global pharmaceutical industry, the safety and reliability of production equipment have become critical to ensuring product quality and operational efficiency. The AKUSENSE Safety Door Lock Series (AR1, AR2, AR3), with its superior electromechanical performance and intelligent design, is revolutionizing door status monitoring and pharmaceutical filling processes. This article explores AKUSENSE’s technical advantages, application scenarios, and alignment with industry trends to demonstrate how it delivers efficient and secure solutions for pharmaceutical manufacturing.

1. Technical Features: Precision, Durability, and Adaptability

-

High Locking Force & Emergency Disengagement

With a locking force of 1,300N and a minimum disengagement force of 60N (AR2/AR3), AKUSENSE ensures immediate circuit cutoff under abnormal tension, preventing operational errors or tampering. The 10mm pre-travel disengagement mechanism guarantees rapid door locking during emergencies, mitigating risks of drug contamination or leakage. -

IP67 Protection & Environmental Resilience

All series meet IP67 standards (complete dust and water resistance), ideal for cleanroom environments with high humidity (up to 95% RH) and temperature fluctuations (-10°C to +70°C). PA66 flame-retardant materials enhance corrosion resistance, aligning with stringent pharmaceutical hygiene requirements. -

Longevity & High-Frequency Operation

The AR3 series offers an electrical lifespan of 500,000 cycles (AC240V 3A) and a mechanical lifespan exceeding 1 million cycles, significantly reducing maintenance costs. The AR2 series supports 30 operations/minute, meeting rapid door cycling demands in automated filling lines. -

Flexible Configuration & Smart Monitoring

Multiple contact configurations (e.g., 2NC/1NO, 3NC) and 4-directional mounting options enable compatibility with mechanical locking, electromagnetic release, and hybrid systems. Optional green/orange LED indicators provide real-time status feedback, while integration with AI vision or RFID systems (per product guidelines) enables end-to-end digital oversight.

2. Application Insights: Enhancing Safety & Efficiency in Pharmaceutical Filling

In sterile drug filling processes, precise control of door sealing and status is paramount. AKUSENSE addresses industry challenges through:

-

Contamination Prevention: IP67-rated sealing and PA66 materials block particle/liquid ingress, ensuring aseptic conditions.

-

Real-Time Status Tracking: Micro-switch components and LEDs enable instant monitoring of door closure, guaranteeing airtight sealing before filling.

-

Emergency Response: Upon detecting abnormal vibrations (1,000m/s² shock resistance) or unauthorized access (triggered disengagement), the lock cuts power and triggers alarms, safeguarding equipment and personnel.

Case Study: A European pharmaceutical manufacturer integrated AR3 series locks into its filling line, achieving a 40% reduction in annual maintenance costs. By synchronizing AI vision systems with door status data, the facility boosted production efficiency by 25%.

3. Industry Trends: Intelligence & Compliance-Driven Innovation

Post-pandemic demands for "contactless production" and "data traceability" are reshaping pharmaceutical manufacturing. AKUSENSE aligns with these trends through:

-

Industry 4.0 Integration: Standard (2M) or flexible cable (2ME) connections enable seamless PLC/IoT integration for remote monitoring and predictive maintenance.

-

Global Compliance: EN60947-5-1 pollution degree 3 certification and Class II double insulation meet FDA and GMP safety requirements.

-

Sustainability: 1-million-cycle durability and low contact resistance (≤25mΩ) minimize energy waste and e-waste, supporting green manufacturing.

Conclusion

AKUSENSE Safety Door Locks transcend traditional hardware, serving as pivotal components in pharmaceutical automation. Their technical excellence and adaptability deliver reliable solutions for door safety and filling precision, while driving compliance, cost efficiency, and operational agility. As Industry 4.0 and AI technologies converge, AKUSENSE remains at the forefront of innovation in safety-critical industrial applications.

Related Products

+86 18188641602