Efficient and intelligent, safe and convenient lithium battery intelligent logistics and storage

Efficient and intelligent, safe and convenient lithium battery intelligent logistics and storage

In the lithium battery industry in the tuyere, it has formed a competitive situation at the equipment end, and the battery storage is no exception.In the lithium battery industry in the tuyere, it has formed a competitive situation at the equipment end, and the battery storage is no exception.In terms of the specific needs for warehousing and logistics automation in the production and manufacturing of lithium batteries, because lithium batteries contain a large number of chemical components and have a high density, the safety, reliability and stability requirements of its storage and logistics equipment are much higher than that of ordinary goods.

In order to better meet the customer intelligent factory "wisdom" demand, improve the convenience of power battery industry of raw material storage and handling, reduce the misoperation loss in the sorting process, improve operation efficiency, battery storage industry is also upgrading intelligent logistics system, reduce human participation, greatly improve product consistency.This issue of Xiaoming will bring you for lithium electricity intelligent logistics upgrade program.

Lift-lift-Opphotoelectric limit

PTV-TM20AP and PTV-T500P can be applied to the jacking carrier to detect the soft battery pack tray with and in place, and to detect the opacity above 12mm.Three pairs of photoelectric cells need to be installed here, respectively for deceleration, in place, and for the limit.The sensor has a large emission angle, easy to adjust when installation, and no interference between sensors at 5-10cm.

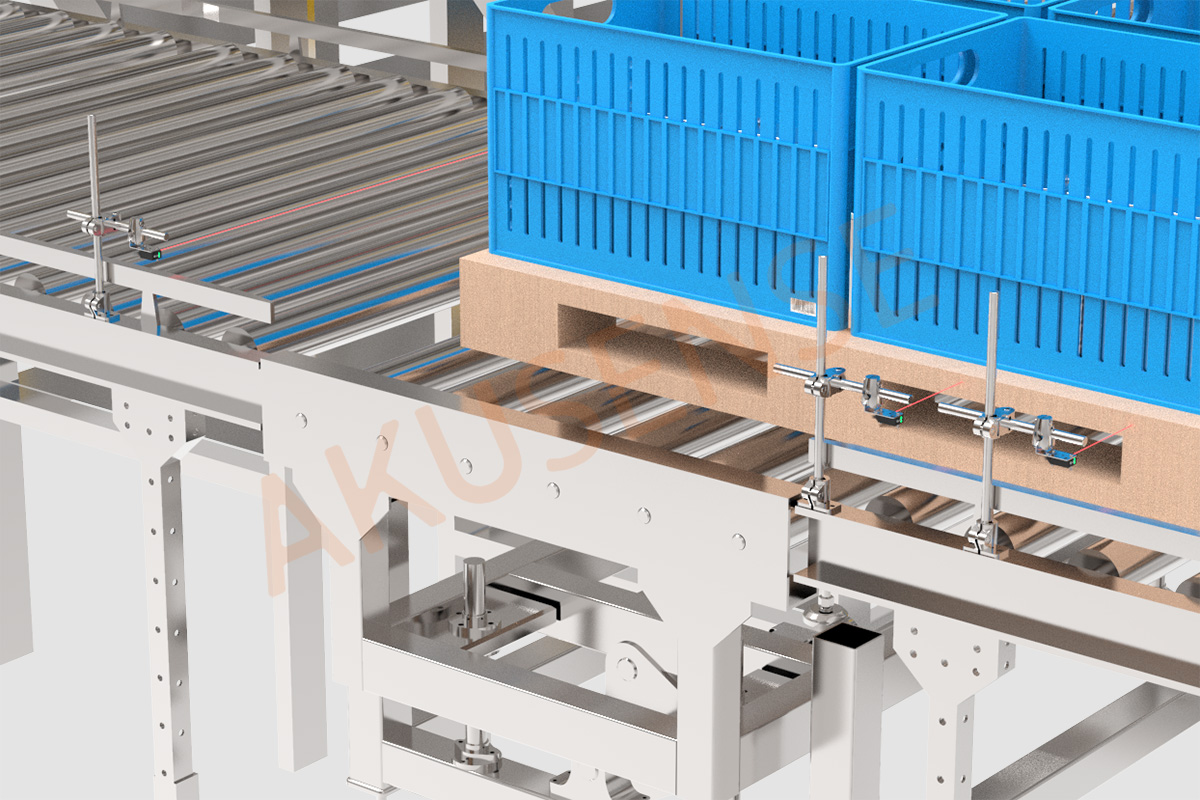

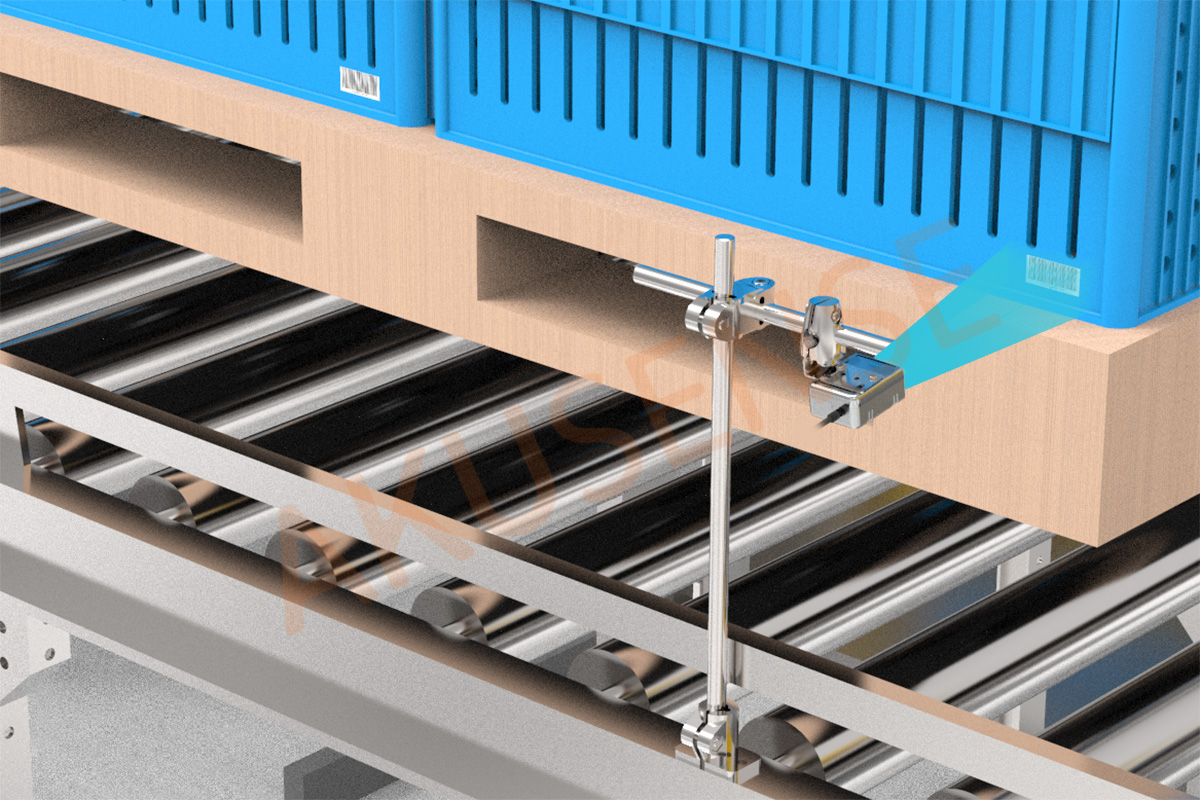

Roller conveyor belt-code reader information traceability

After the first injection of the soft battery pack, the RCD-HSP30 was tilted up to detect the product batch and information was stored for subsequent operations.Realize the whole process of delivery and delivery on shelves, record product information, realize information traceability at any time, and help improve the consistency of battery products.

For intensive one, QR code, RCD-HSP30100 has megapixels, strong resolution and processing capability; excellent software algorithm, fast decoding speed, up to 60ms, can effectively improve the logistics transmission speed; In addition, it can read a specific bar code within a designated point.

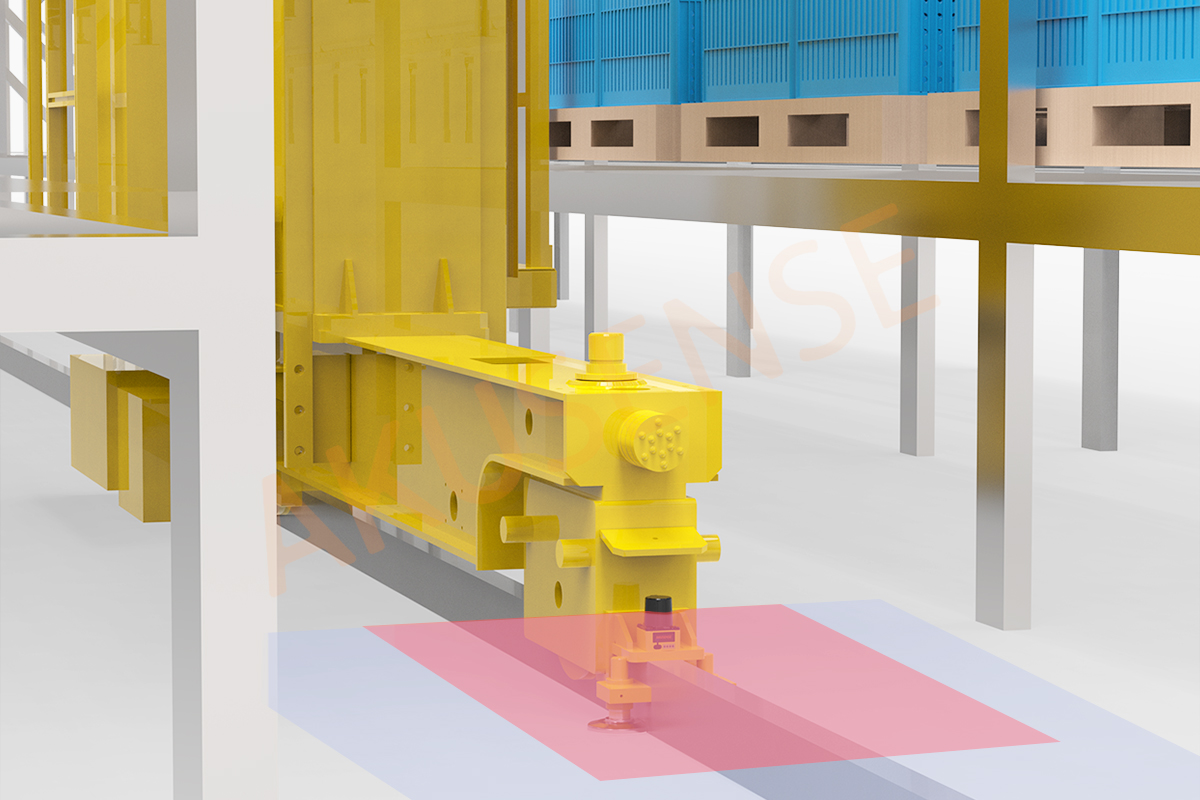

Stacker operation mechanism-Lidar safety obstacle avoidance

The soft battery pack after injection needs to be static, so that the electrolyte can be fully infiltrated. When the battery pack tray needs to be transported to the static bank through the stacker, the radar AS-21C is used for safety obstacle protection.

The Akusense lidar can protect the surrounding 20M range of 300°, with an angular resolution of 0.125°, achieve high precision distance measurement during transportation, greatly improve the regional obstacle avoidance ability; It is equipped with dirty carrying, strong light resistance, rain and fog resistance, which can better adapt to various detection scenarios.Its unique background self-learning function can also be perfectly applied to complex scenarios.

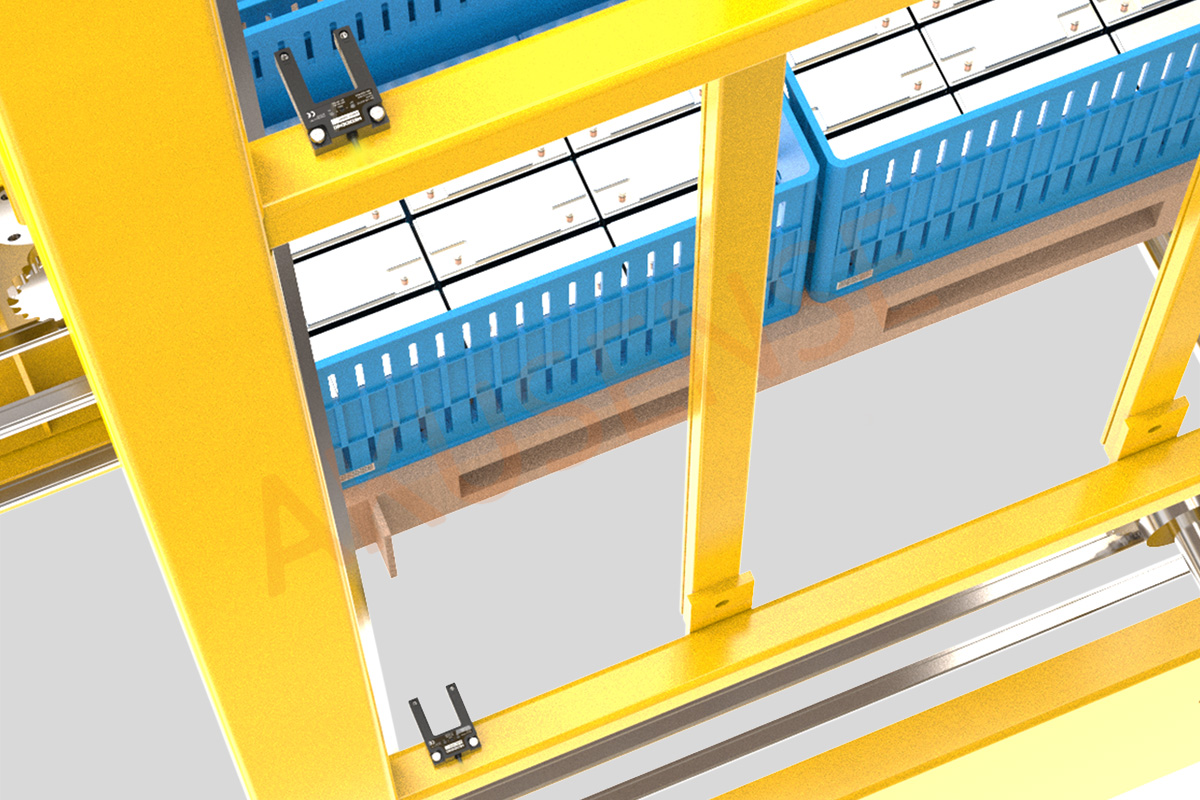

Stacker carrier table-diffuse photoelectrical detection

The cargo platform is connected to the lifting mechanism by a wire rope or chain, and rises up and down along the guide rail on the column.The fork expansion machine is installed on the platform and can be extended in both directions to enter (remove) the container on both sides and run with the platform with the stacker in the roadway.

Diffuse photoelectric PTE-D70 detects obstacles in front of the fork, gives quick feedback to the control center and the response speed is <1ms to prevent unnecessary loss caused by the obstacle in the roadway; its anti-interference performance is superior and high long-term stability.

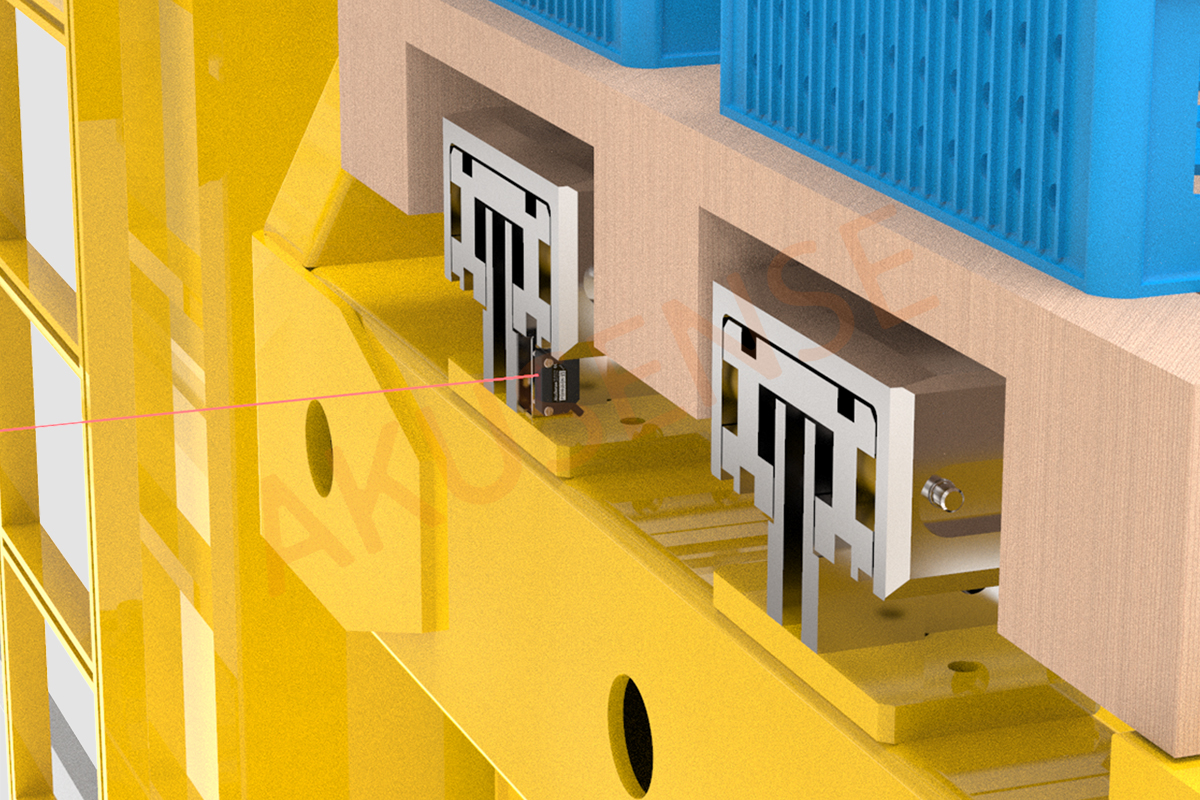

Hoist-slot-type sensor

In the process of the soft battery pack air carrier backflow transportation and transportation up and down the elevator, as the "joint" of the precise movement of the mechanism, the groove sensor plays the role of deceleration and restriction here.Due to the vibration of the mechanism movement and the slight offset, the 30mm wide slot KIM30-0304P sensor can effectively avoid the elevator from hitting the sensor due to the too narrow slot position, causing damage.

Its response speed is 1ms, which can detect opaque objects of more than 2mm, with strong anti-interference performance, which can support the high-speed operation of the equipment, and effectively improve the production capacity.

Akusense Sensor focuses on the lithium battery industry, always creating value around customers to realize perception, diagnosis, prediction and feedback.We hope to work together with our partners to form industrial synergy, help our partners' product breakthroughs with advanced and stable products, and jointly drive the development of lithium electric intelligent manufacturing.