Inspection

Sectors Filter

- Semiconductor

- 3C Electronics

- Package

- Automobiles

- logistics

- New energy

Control the temperature of the mixer

After the positive and negative materials are uniformly mixed by a vacuum mixer, they are stirred into slurry.

Detect the te mperature of the drying oven

The drying box is electrically heated, with uniform heating, precise temperature control and rapid drying.

Detect the position of the core coil material

After the materials and the separator are wound into small cell monomers, tape should be attached to prevent the cell from loosening or shifting. The photoelectric sensor is used to detect the position of cell roll material. The material will be moved to the next step if the replacement is right.

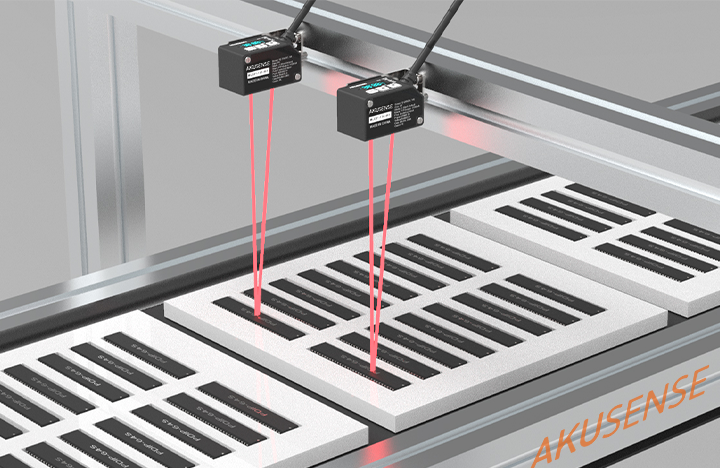

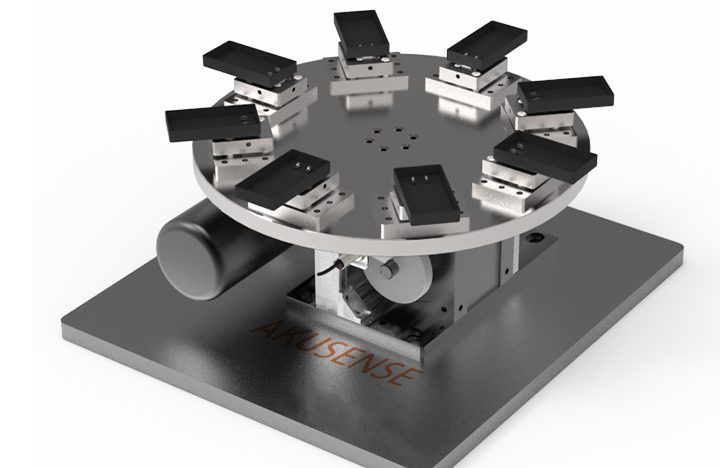

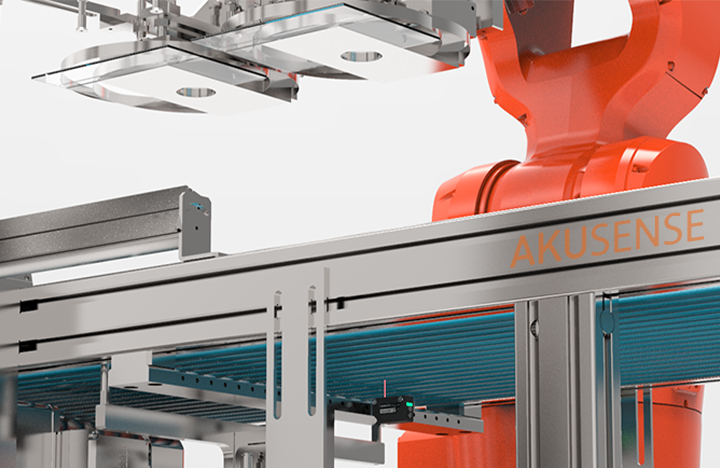

Detect whether the wafers are placed accurately

Check whether the wafer placement is accurate

Detection the bulge of lithium batteries in production

During the battery bulge inspection process, the bulge height is detected to ensure that the batteries does not leak, blemish and avoid the defective products flow into the next step.

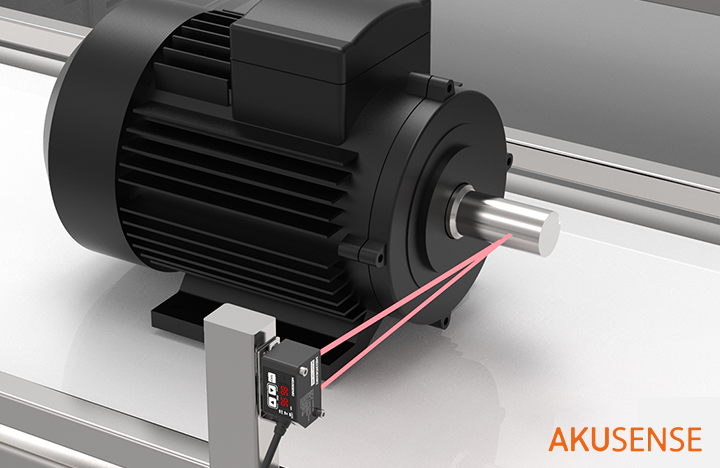

Motor detection

In the production process of the motor, it is ensured that the size of the product is accurate and the shape is error-free.

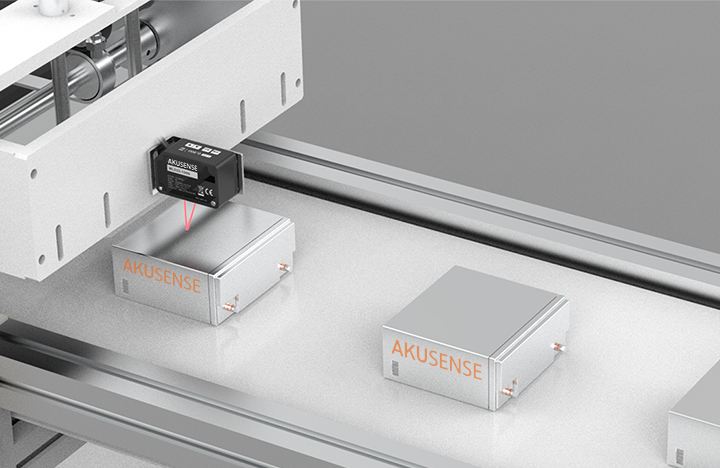

Detect the integrity of the product in the package

Check whether the product in the package is intact.

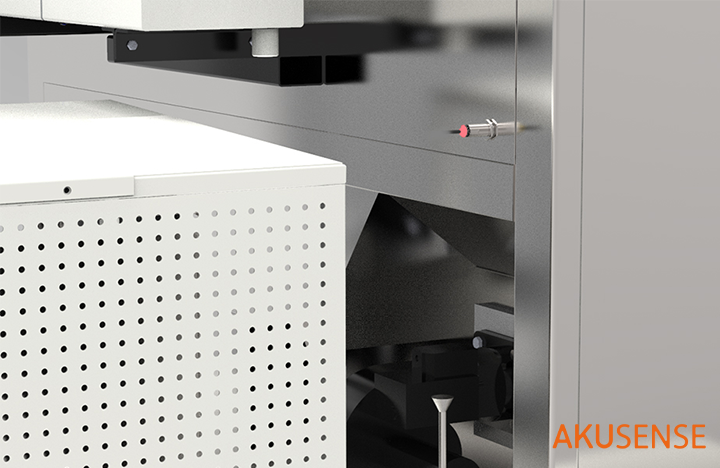

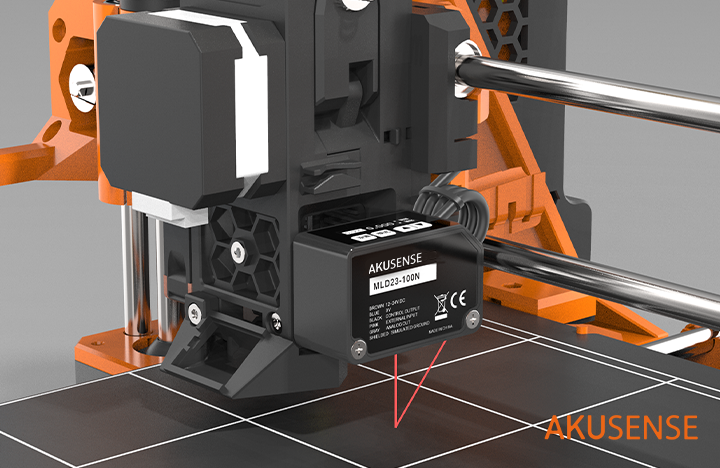

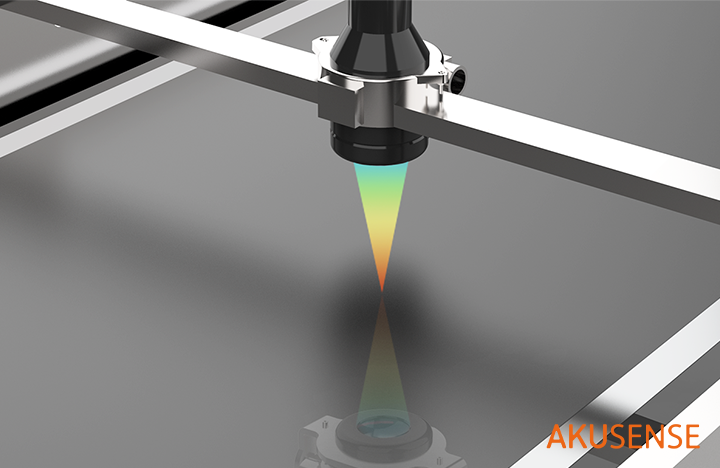

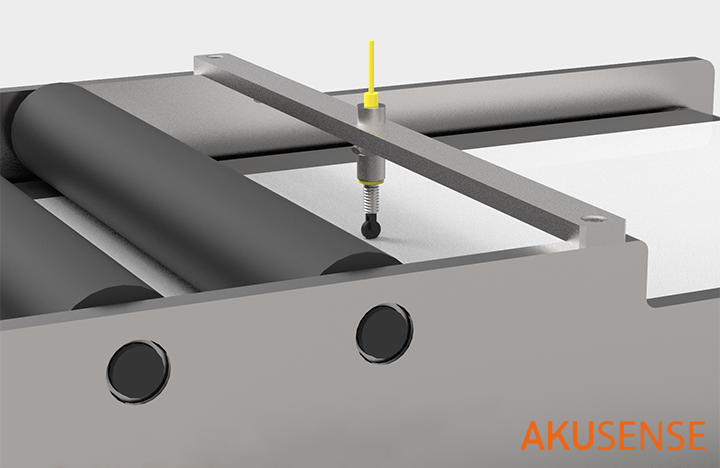

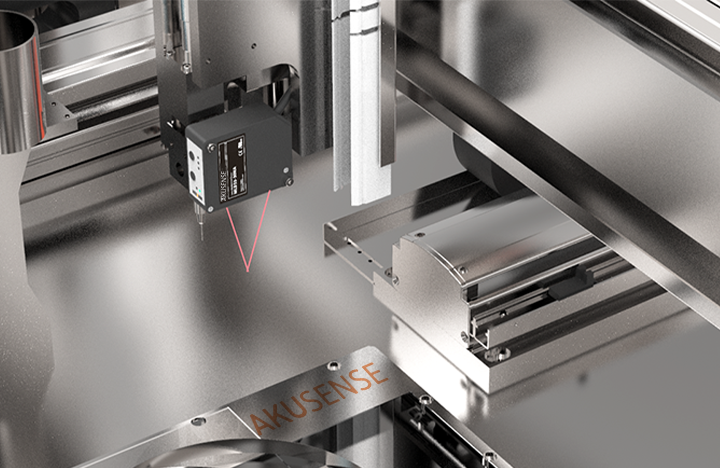

3D printer position detection

A 3D printer with an automatic nozzle height positioning system can confirm whether the height of the nozzle meets the requirements of the printing height according to the height data measured by the displacement sensor, and realize the accurate positioning of the nozzle height to prevent the print adhesion or scraping.

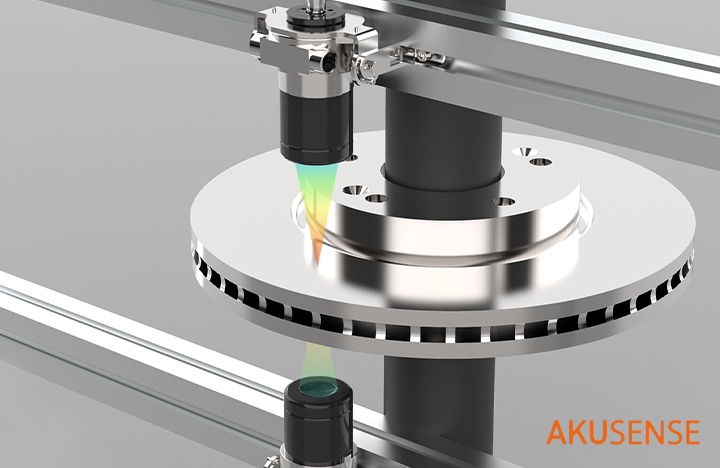

Automobile brake disc thickness detection

ADV-12CK2 series of spectral confocal sensors can be equipped with dual probes,which can be used to detect the thickness of automobile brake discs online. The confocal sensor adopts the principle of non-contact spectral confocal detection,with fast response speed, non-contact and no damage to the surface of the brake disc.

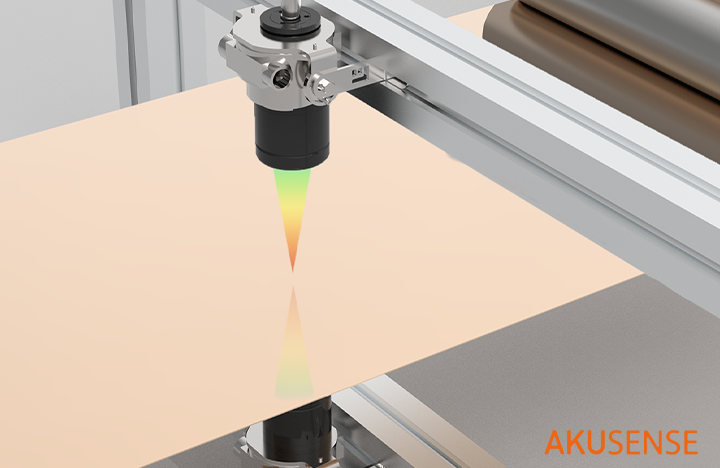

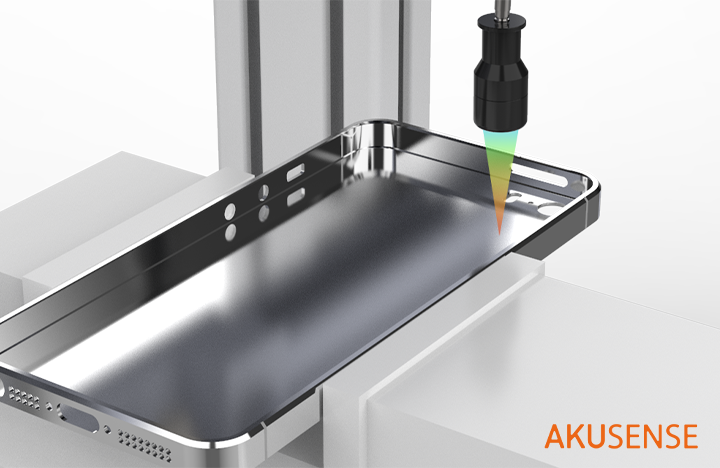

Sheet metal thickness detection

ADV-12CK2 can be used to detect the thinckness of the metal sheet.

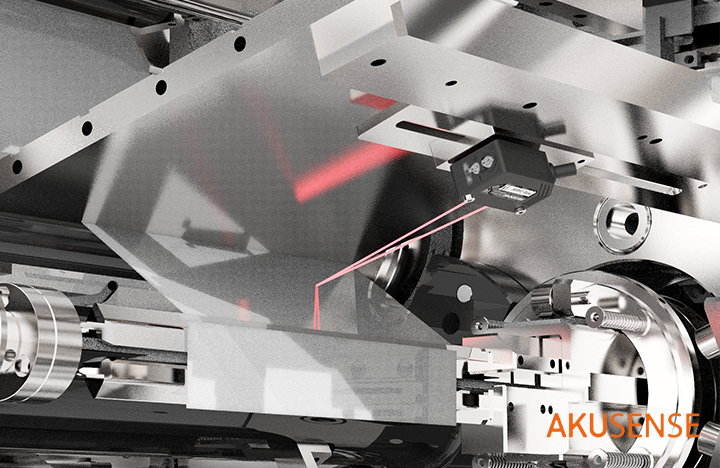

Electrode coating thickness detection

Based on the characteristics and the high-precision requirements of the battery pole pieces, it is a relatively reliable solution to use a confocal displacement sensor. ADV series spectral confocal can be equipped with two probes at the same time. It is the best choice for online beam detection of pole piece and coating thickness, which is economical, stable and reliable.

Film tension measurement

In the process of processing the membrane into individual electrodes and separator plates, stress must be maintained on the membrane web. cylinder magnetic MR-C8 uses the position of the reversing roller to measure the film tension.

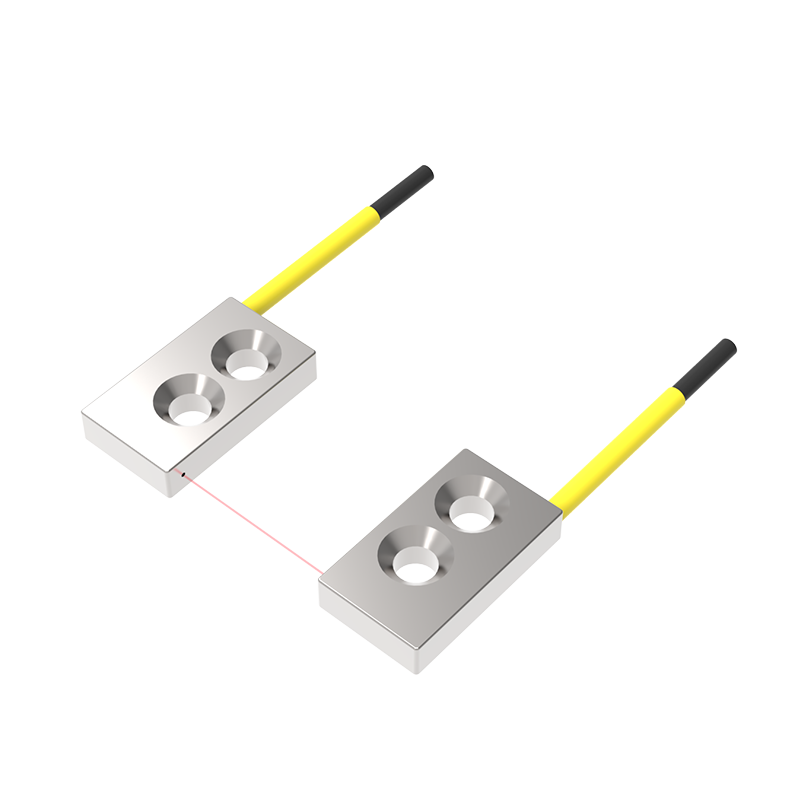

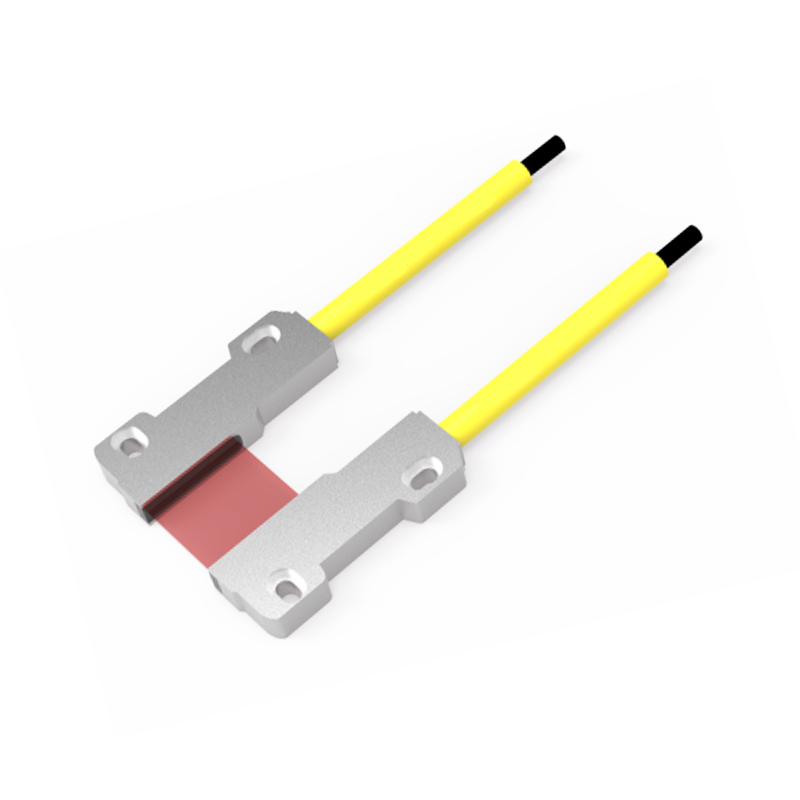

Security Door Protection

The door magnet MR-D2 monitors the door with protection function, which can be installed flexibly and has excellent operational safety, which can make sure that the running machine stops when the door is opened and can only be started when the door is closed.

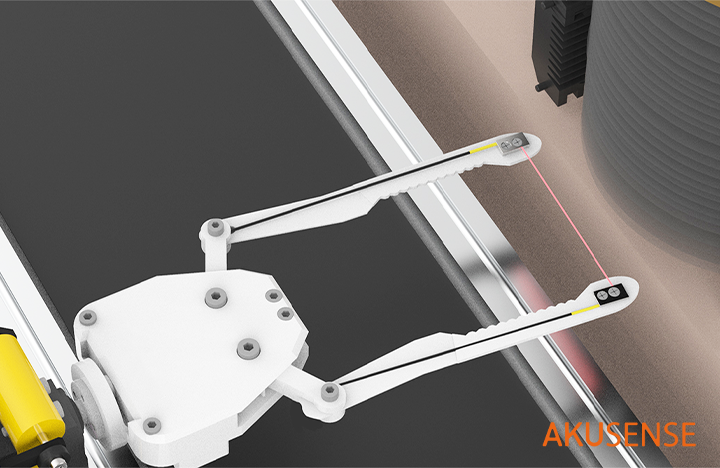

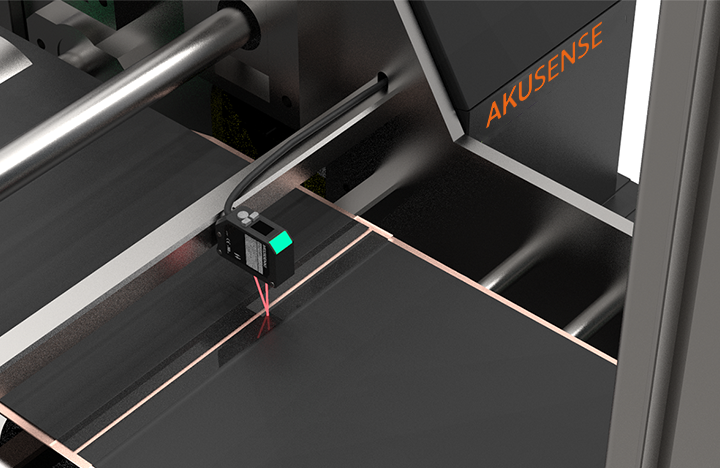

Splicing tape detection

When replacing the roll, the end and the beginning of the two rolls that are next to each other should be connected with splicing tape. colour / the color mark sensor can stably detect the splicing tape so that it can be removed before the film is processed into units.

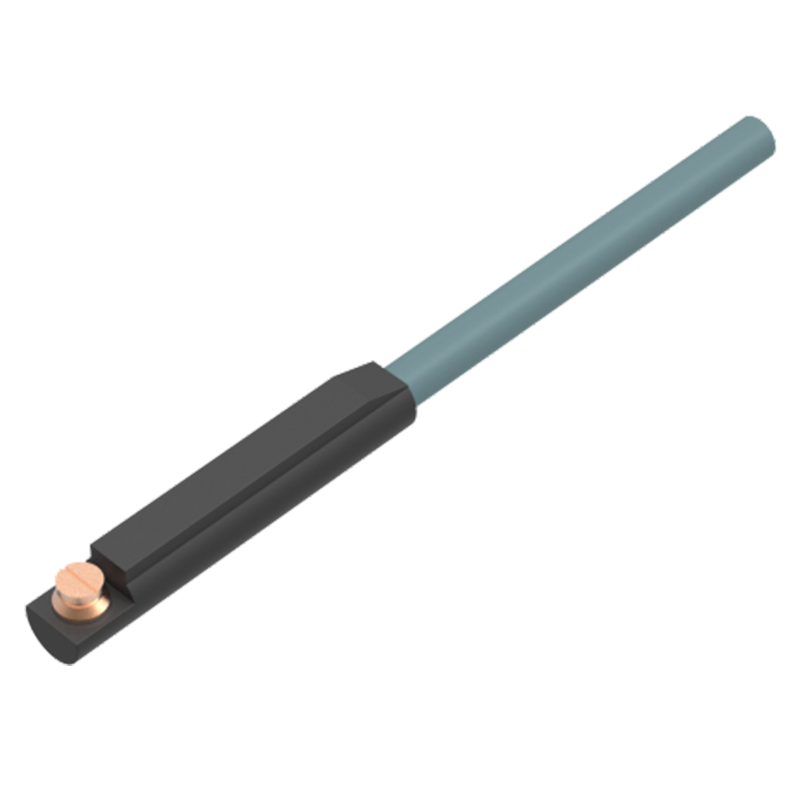

Prevent paper re-feeding detection

Use a contact sensor to detect the thickness of the paper to prevent multiple sheets from being taken out repeatedly.

Multi-sheet detection of separator plate

Ultrasonic MUD series accurately detect the adjacent suspended electrodes and minimize defective products. Electrode and separation,The stacking of the device board is very important for the manufacture of battery cells.

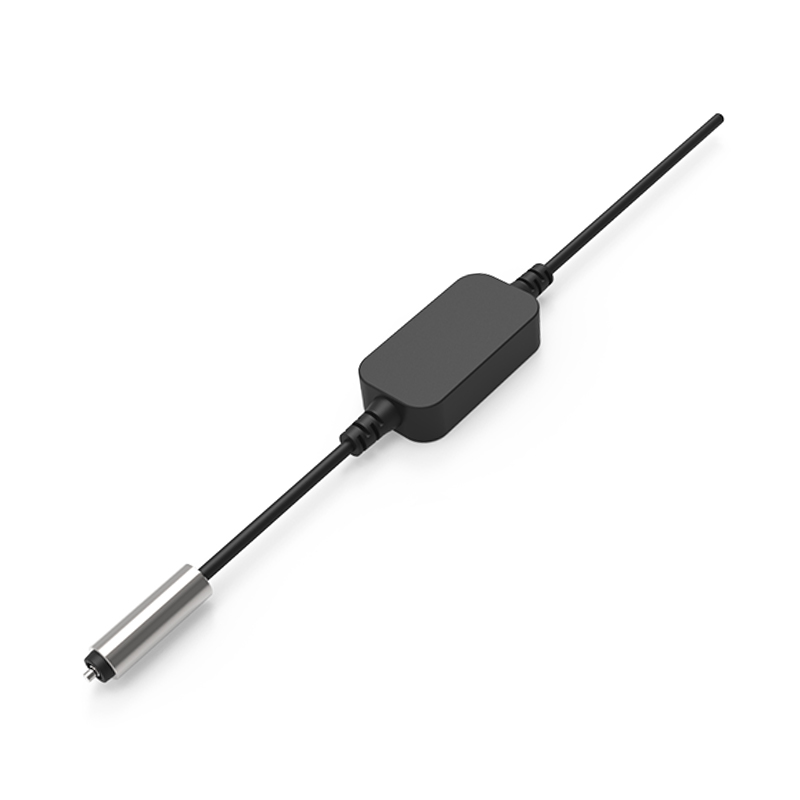

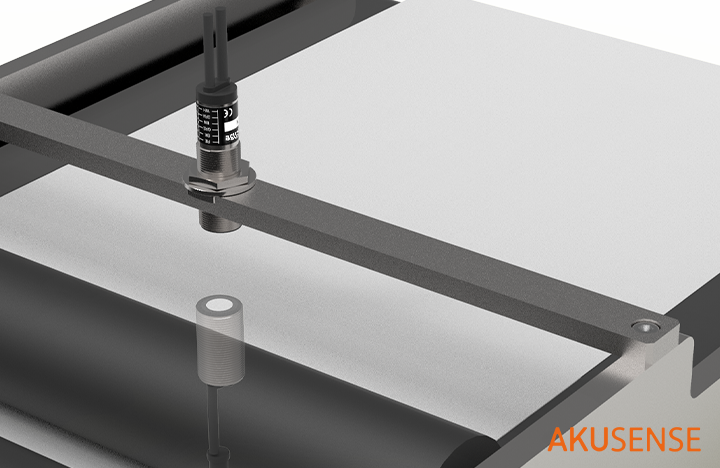

Detect the rotation stop to circulate the assembled product

An inductive sensor is used to detect the stop of rotation to cycle the assembled product.

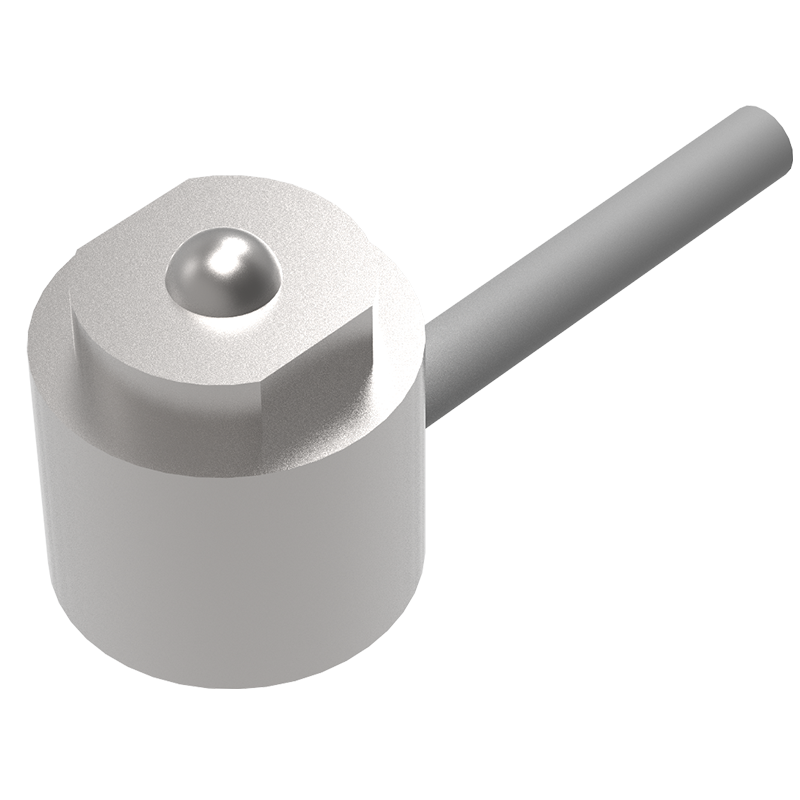

Measure the press-in point of stamping parts

Precision measurement, testing the height of the metal parts die casting, precision can reach μ levels.

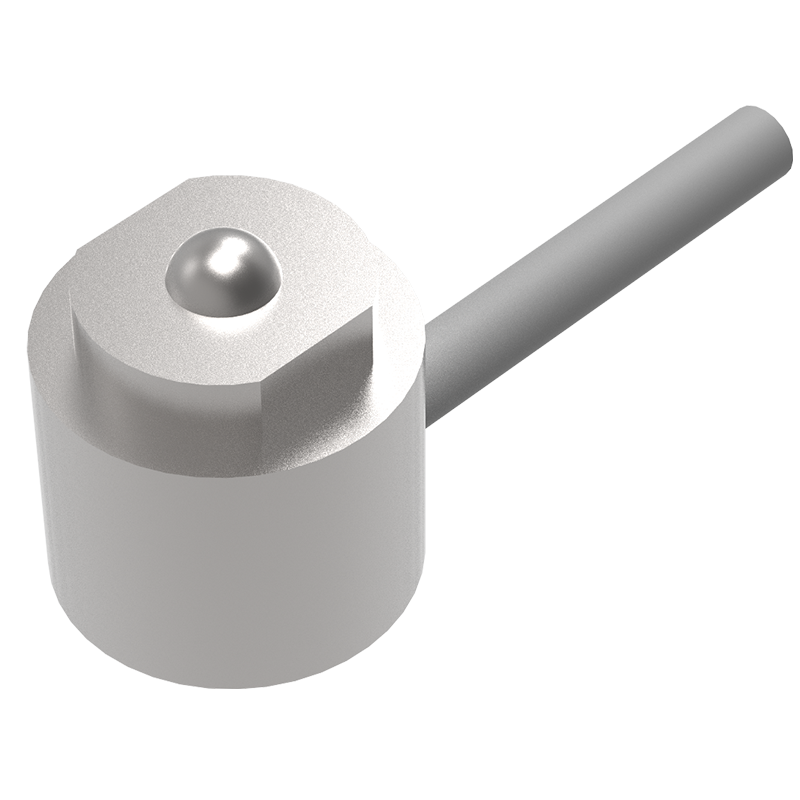

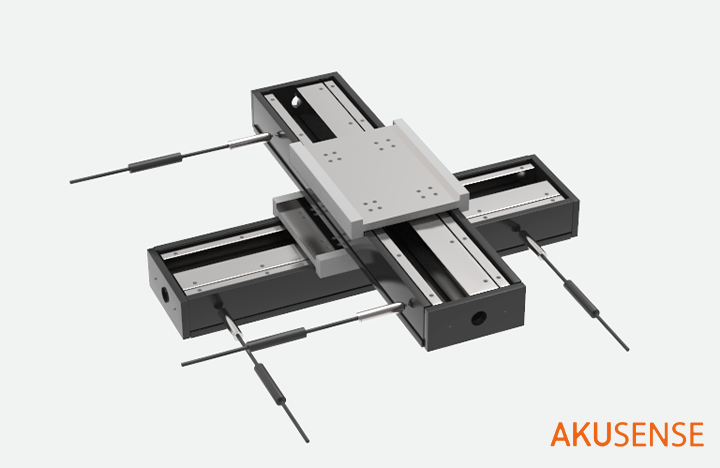

Measure the position of the XY platform

Precision contact positioning sensor for μm level positioning accuracy.

Measure the size of auto parts

Precisely inspect the height data of each point of auto parts to determine whether they are qualified.

Measuring the height of the screw after tightening

Check whether the screw height after tightening is within the calibration range and the error of screw height.

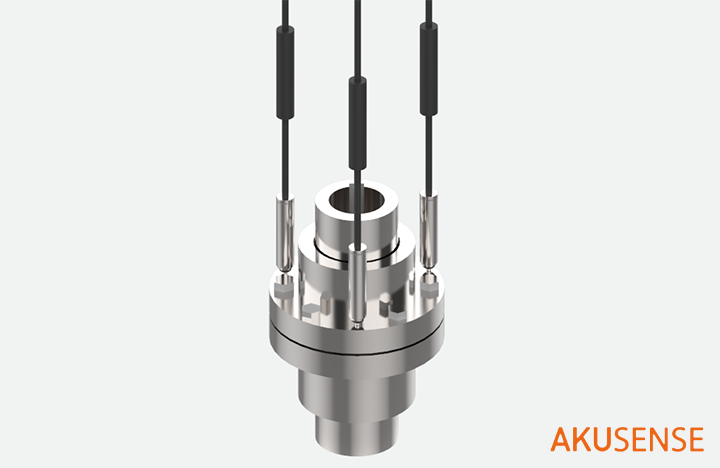

Assembly inspection of coupling

The contact displacement sensor detects the assembly error of the coupling.

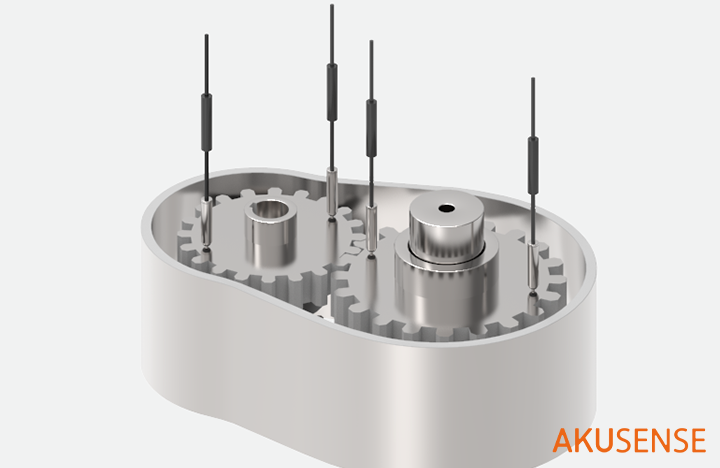

Measure the height of gearbox components

Contact probe can measure the installation flatness of gear and adjust the installation of gear.

Measure the characteristic dimensions of precision machined parts

Measuring the dimensions of precision machined parts.

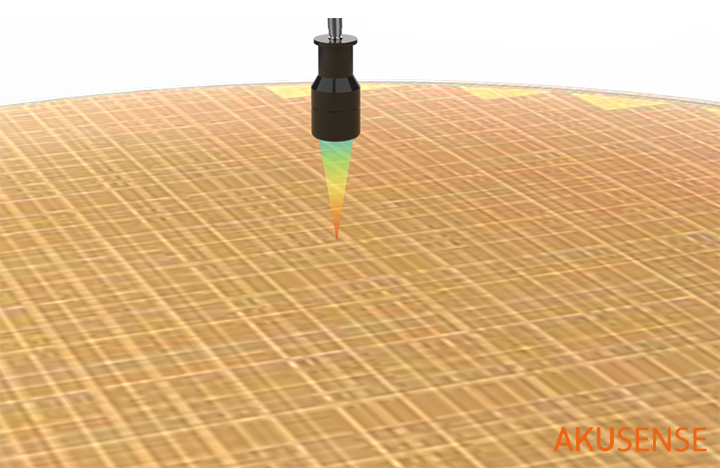

Measure wafer thickness and flatness

Measuring thickness and flatness of wafer.

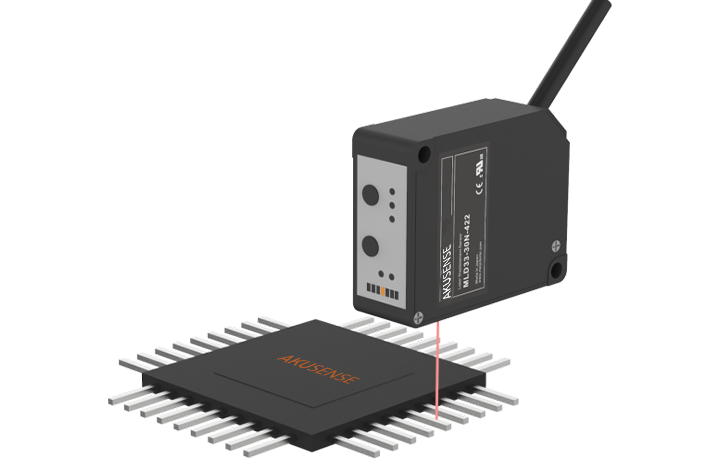

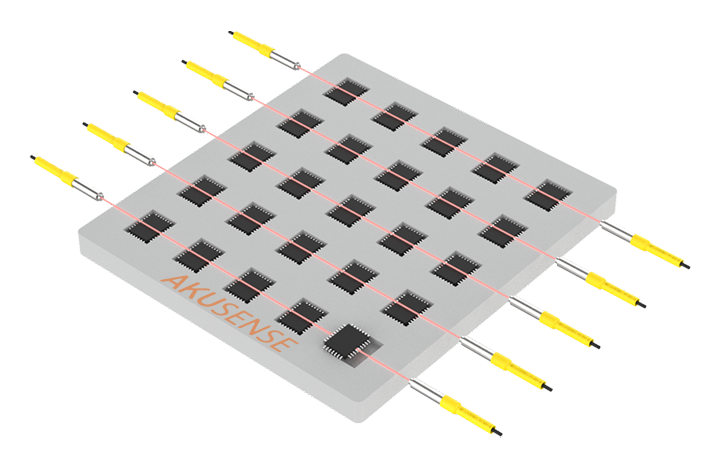

Use the IC tester to detect the workpiece

Check the bending degree of the pin with a high-speed drastic position meter.

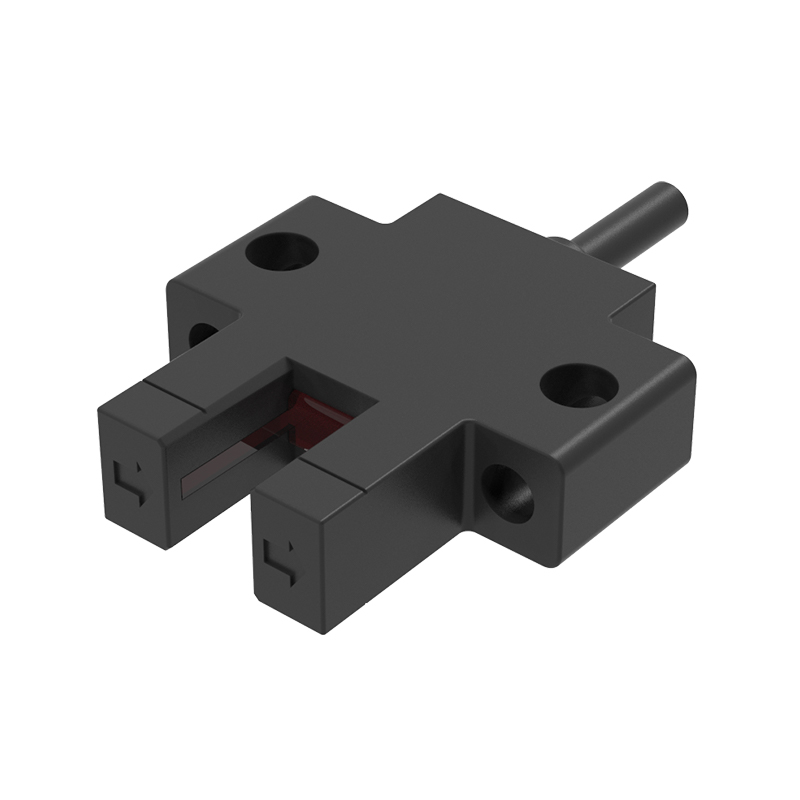

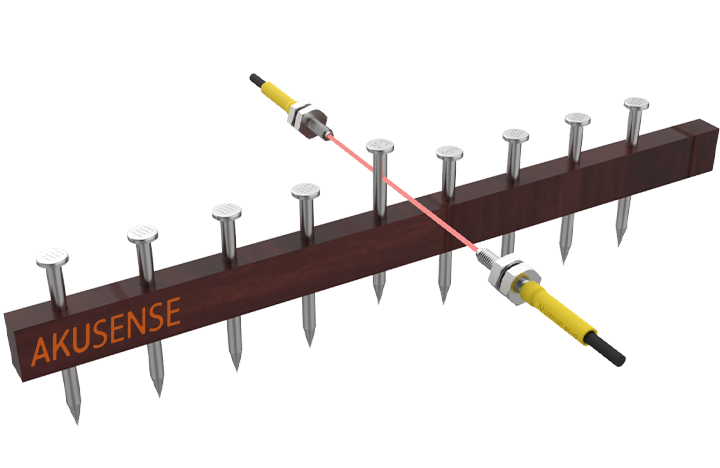

Detection of bad nail tape

Use the penetrating photoelectric sensor to detect nails with poor adhesive position.

Printing paper 2 sheets feed detection

Adjust the speed by the beat rate of the pressing or stamping process. The distance between the plate and the sensor is used as a signal to control the speed of the motor.

Detect the wear of small diameter drill bits

The contact sensor detects the abrasion of the cutter head and decides whether to change the cutter.

Detect the height difference of resistance before welding

Using the C-MOS sensor background suppression ELS-ZL70 can detect subtle height differences.

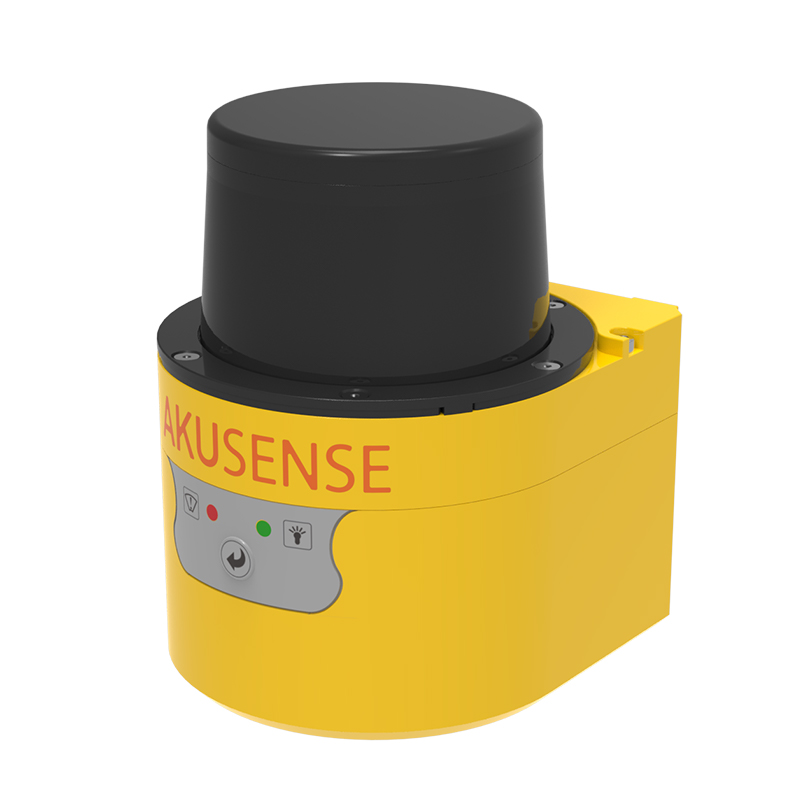

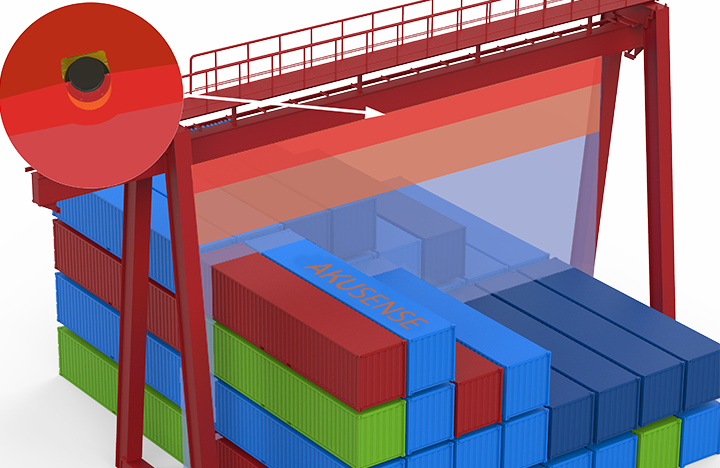

Container stack measurement

LiDAR AS-21C scans the stack of containers under the gantry crane, and then uses software processing to avoid collisions when lifting and fixing the container with a spreader.

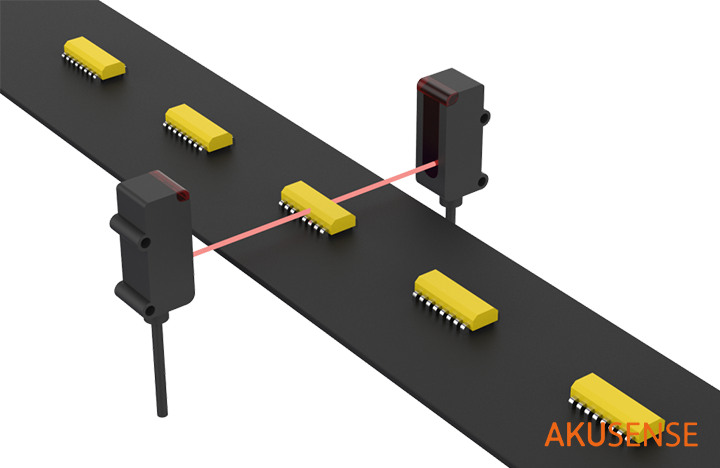

Small included angle through beam photoelectric

Detecting the passage of flat items accurately.

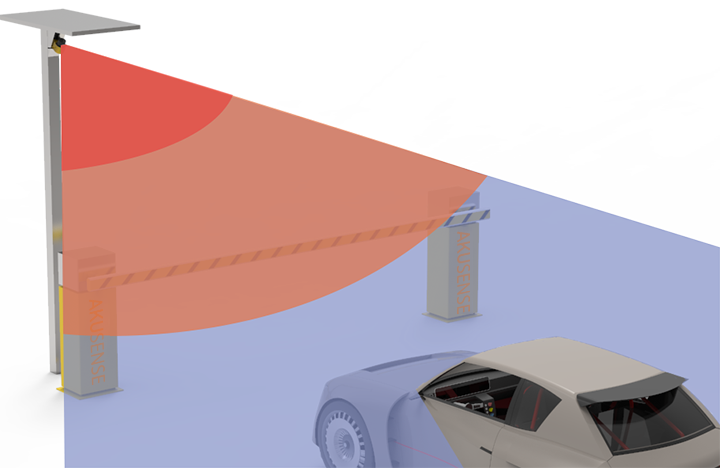

Parking lot vehicle detection

The AS-21C lidar sensor can be used for vehicle position detection and can trigger the gate system to achieve functions such as capture and billing.

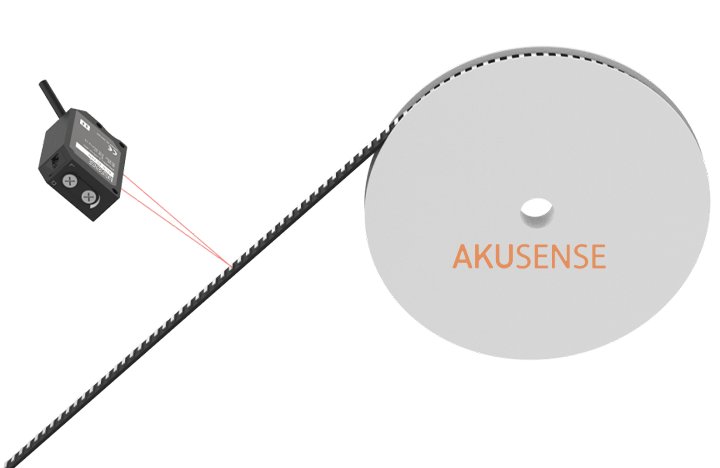

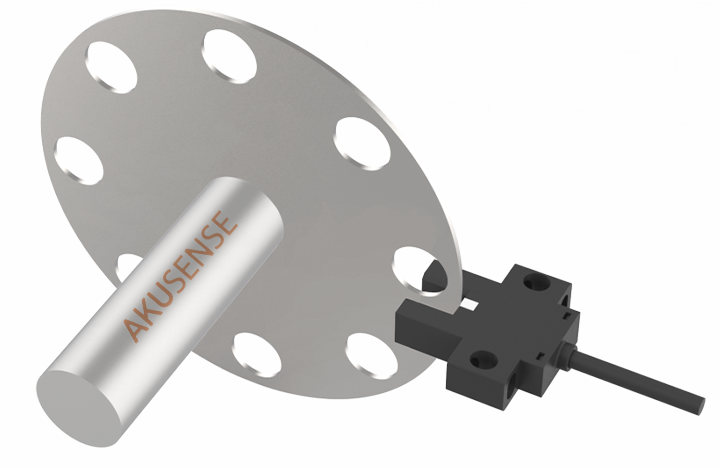

Axis rotation reading sensor

Check out the turning of circular plate hole, read revolutions and speed.

Check the flatness of the brake pads

Measure the relative position (height) of the front end and brake surface of the metal part PWI (Pad Wear Indicator).

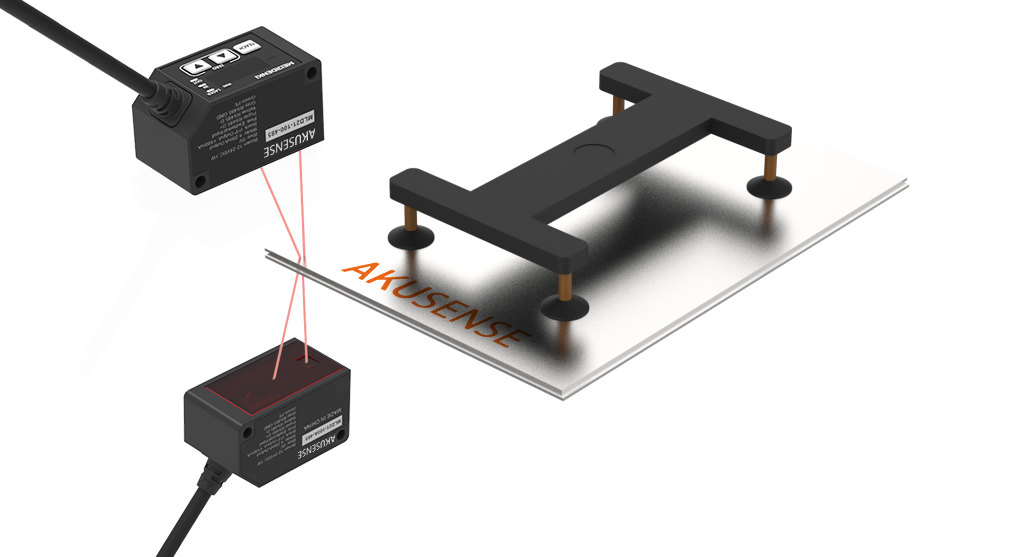

Detect double-layer sheet metal

Detect double-layer metal plates during transportation. MLD22 can measure 12 points at the same time with high speed and accuracy.

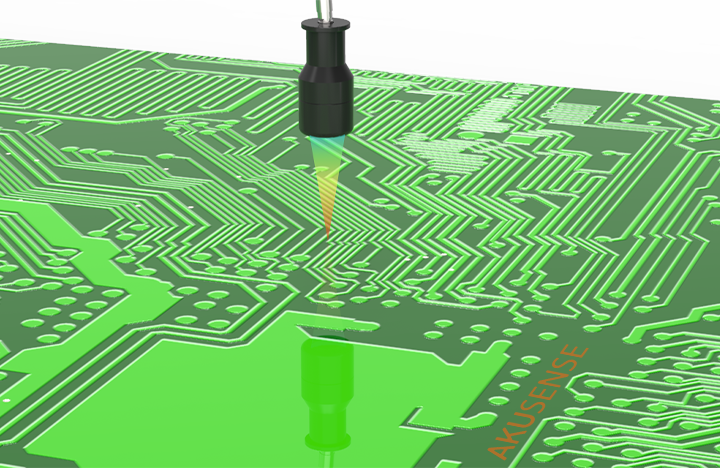

Measuring the flatness and segmentation of PCB board

Measuring the flatness and segmentation of PCB board.

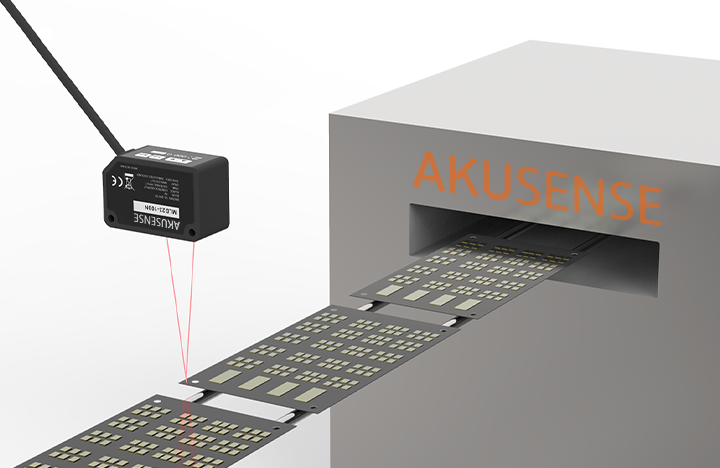

Detection of substrate warpage

The laser displacement sensor can accurately detect the warping range of the substrate.

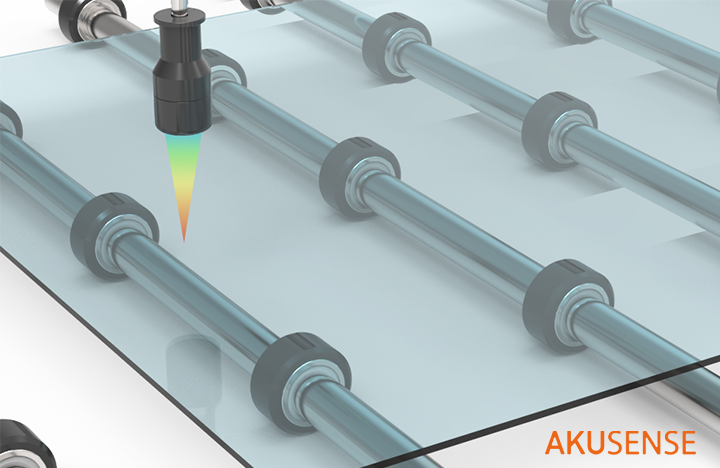

Measuring the flatness and thickness of the glass

Measuring the flatness and thickness of the glass

Outside diameter classification detection

Using a wide range of light and two output sensors, the outside diameter of the material is sorted and detected.

Check whether the chip is flat or not

The tiny optical fiber can detect the warpage of the tiny chip. The narrow beam projected from the ultra-fine fiber core can identify subtle changes.Sectors Filter

- Semiconductor

- 3C Electronics

- Package

- Automobiles

- logistics

- New energy